Plastic part manufacturing drives industries from automotive to medical devices. The processes used, such as injection molding, extrusion, blow molding, and 3D printing, determine part quality, consistency, and performance.

Choosing the wrong process or ignoring material characteristics can cause warping, cracking, or dimensional errors. Using the right plastic manufacturing processes ensures parts meet design needs while reducing waste and delays.

It is not just about machines; precision in selecting the correct process for the material and production volume is key. High-volume rigid parts suit injection molding, while intricate low-volume components fit 3D printing.

If you are producing plastic components or managing a line, these choices directly impact quality and efficiency.

In this article, we will cover key plastic part manufacturing techniques and actionable insights to optimize production and control costs.

Key Takeaways:

Choosing the right plastic part manufacturing process is critical to avoid defects such as warping, cracking, or dimensional errors and to ensure consistent part quality.

Process control including temperature, pressure, cooling, and material handling directly affects yield, scrap reduction, and overall operational efficiency.

Tooling and mold design strongly influence accuracy, part consistency, and cycle times. Features such as gate placement, cooling channels, and venting help prevent common defects.

Automation and real-time monitoring improve repeatability, reduce human error, and maintain stable production workflows across different techniques.

Emerging trends like sustainability, smart manufacturing, and advances in 3D printing are reshaping the industry by enabling eco-friendly materials, faster production, and more complex part designs.

Aligning material properties, production volume, and part complexity with the appropriate manufacturing method optimizes cost, quality, and efficiency across the production line.

How Plastic Part Manufacturing Works: A Simple Overview

Plastic part manufacturing is the process of shaping polymers into functional components using methods like injection molding, extrusion, blow molding, thermoforming, and 3D printing. Each process applies heat, pressure, and shaping forces to achieve the desired geometry while maintaining material properties.

The process works by feeding the polymer in the correct form, shaping it under controlled conditions, and allowing it to cool or cure gradually to stabilize dimensions.

The basic sequence:

Feed the polymer into the chosen process

Shape the part with precise temperature and pressure control

Cool or cure the part gradually to ensure dimensional stability

During production, plastics can experience rapid cooling, uneven pressure, or mechanical deformation. These factors can create internal stresses, warping, or surface imperfections that compromise part quality.

By understanding the material, part design, and production method, manufacturers can produce high-quality plastic parts efficiently while controlling costs and waste.

Even the most advanced plastic manufacturing process only delivers consistent results when melt preparation, delivery, and monitoring are precise.

That’s where MD Plastics comes in, with systems like Inject-EX™ Plasticating Systems, Posi-Melt™ Multipurpose Screws for monitoring and purging, and solutions that connect every stage of production for smooth, reliable, and high-quality parts.

Key Plastic Part Manufacturing Techniques

Choosing the right manufacturing technique prevents defects, reduces waste, and keeps production on schedule. Techniques like injection molding, blow molding, extrusion, rotational molding, thermoforming, compression molding, and 3D printing address specific production challenges.

Each method improves part quality, lowers costs, and fits the volume and complexity requirements of your application.

The table below shows the most common plastic part manufacturing techniques, their typical applications, and widely used materials:

Technique | Applications | Common Materials |

Injection Molding | Automotive components, medical devices, consumer electronics | ABS, Polycarbonate (PC), Acetal (POM), Nylon (PA) |

Blow Molding | Bottles, containers, automotive fuel tanks | HDPE, PET, Polypropylene (PP) |

Extrusion Molding | Pipes, packaging films, window frames, and decking | PVC, HDPE, Polypropylene (PP), ABS |

Rotational Molding | Storage tanks, playground equipment, large containers, kayaks | Polyethylene (PE), Polypropylene (PP) |

Thermoforming | Packaging trays, automotive panels, appliance components, signage | Polystyrene (PS), PVC, PETG |

Compression Molding | Automotive panels, electrical components, and industrial housings | Thermosetting composites (SMC, BMC) |

3D Printing | Rapid prototypes, custom parts, low-volume manufacturing | PLA, ABS, Nylon, PETG, other additive thermoplastics |

In the following sections, you’ll explore each method in detail, explaining how it works, why it matters, and the best practices to achieve high-quality parts.

1. Injection Molding

Injection molding is one of the most widely used plastic manufacturing processes. In this method, molten plastic is injected under high pressure into a mold cavity, where it cools and solidifies to form the desired shape.

How it works: Plastic pellets are melted in a heated barrel, then forced into the mold using a screw or plunger. After cooling, the part is ejected, ready for use or assembly.

Why it matters: Maintaining consistent temperature, pressure, and cooling time is critical to prevent defects such as warping, sink marks, or incomplete filling. Proper control ensures repeatable, high-quality parts.

Applications: Automotive components, medical devices, consumer electronics

Common Materials: ABS, Polycarbonate (PC), Acetal (POM), Nylon (PA)

2. Blow Molding

Blow molding is a key process for producing hollow plastic components. In this method, a molten tube of plastic, called a parison, is inflated inside a mold to take the desired shape.

How it works: The process begins with extruding a parison from the plastic melt. This parison is then clamped inside a mold and expanded using compressed air so that it conforms to the mold walls. After sufficient cooling, the mold opens, and the finished part is ejected.

Why it matters: Consistent control of parison thickness, mold temperature, and air pressure is essential to avoid weak spots, uneven wall thickness, or pinholes. Any variation can compromise structural integrity, leading to defects or rejected parts.

Applications: Bottles, containers, automotive fuel tanks, and other hollow components where uniform wall strength is critical.

Common Materials: HDPE, PET, Polypropylene (PP)

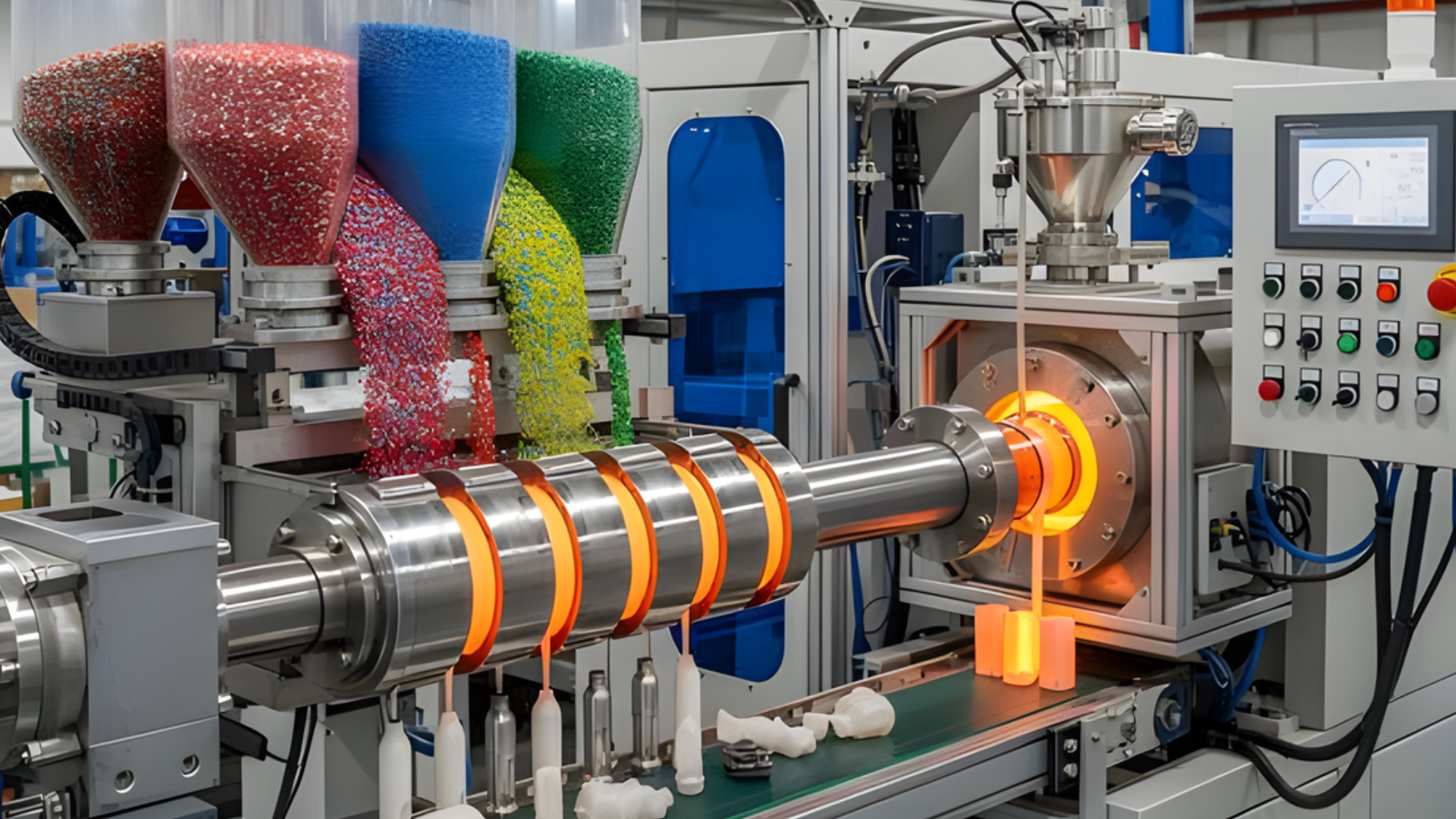

3. Extrusion Molding

Extrusion molding is a key process for producing continuous plastic shapes such as pipes, sheets, and profiles. In this method, molten plastic is forced through a shaped die to create the desired cross-sectional profile.

How it works: The plastic pellets are melted in a heated barrel and pushed through the die using a screw or ram. As the material exits the die, it is cooled, typically with water or air, and then cut to the required length. This produces long, uniform shapes with consistent dimensions.

Why it matters: Maintaining consistent barrel temperature, precise die design, and controlled cooling is essential to prevent surface defects, warping, or internal stresses. Any variation can affect dimensional accuracy and part performance, leading to rejected products.

Applications: Pipes, packaging films, window frames, decking, and structural profiles.

Common Materials: PVC, HDPE, Polypropylene (PP), ABS

4. Rotational Molding

Rotational molding is a process used to create large, hollow plastic components with uniform wall thickness. In this method, plastic powder is heated inside a mold that rotates along two perpendicular axes.

How it works: The mold rotates continuously while being heated, causing the plastic powder to melt and coat the interior evenly. After reaching the desired thickness, the mold is cooled, and the finished part is removed. This produces stress-free parts with minimal deformation.

Why it matters: Controlling rotation speed, heating temperature, and cycle time is critical to ensure uniform wall thickness and avoid weak spots. Very thick sections may require multi-stage heating or extended cycles for complete material fusion.

Applications: Storage tanks, playground equipment, large containers, kayaks, and industrial housings.

Common Materials: Polyethylene (PE), Polypropylene (PP)

5. Thermoforming

Thermoforming is a process used to shape plastic sheets into precise forms using heat and vacuum or pressure. It is ideal for producing low- to medium-volume parts with consistent quality.

How it works: Plastic sheets are heated until pliable and then pressed against a mold using vacuum or mechanical pressure. Once the material cools and solidifies, excess material is trimmed to achieve the final dimensions.

Why it matters: Consistent sheet heating prevents thinning or weak spots, while accurate mold alignment ensures the part meets dimensional requirements. Careful control of vacuum and pressure is essential to maintain uniform wall thickness and surface quality.

Applications: Packaging trays, automotive panels, appliance components, signage, and protective covers.

Common Materials: Polystyrene (PS), Polyvinyl Chloride (PVC), PETG

6. Compression Molding

Compression molding is a process that uses heat and pressure to shape polymer materials into solid components. It is particularly suited for large or simple parts where material efficiency and strength are essential.

How it works: The polymer material is placed in a heated mold cavity and compressed until it conforms to the mold shape. Once cooled, the part is removed and ready for use.

Why it matters: Controlling temperature, pressure, and hold time is crucial to achieve uniform density, high surface quality, and minimal flash. Proper venting ensures trapped gases are released, preventing voids or internal defects.

Applications: Automotive panels, electrical components, industrial equipment housings, and large molded items.

Common Materials: Thermosetting composites such as Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC)

7. 3D Printing

3D printing is an additive manufacturing process that creates parts layer by layer directly from a digital model. Unlike traditional molding techniques, it allows for highly customized or low-volume production, making it ideal for prototyping and specialized components.

How it works: Material, such as filament, resin, or powder, is deposited or cured layer by layer to gradually form the part. After printing, post-processing steps like sanding, polishing, or curing enhance dimensional accuracy and surface finish.

Why it matters: Careful control of layer adhesion, temperature, and print speed is crucial to ensure strength, precision, and consistent quality. Without proper settings, parts may warp, shrink, or develop weak spots, especially for larger components.

Applications: Rapid prototypes, custom or low-volume parts, design verification models, and specialized manufacturing needs.

Common Materials: PLA, ABS, Nylon, PETG, and other thermoplastics suitable for additive processes

Also Read: Designing Custom Screws for High-Temperature & Bio-Based Polymers

Factors to Consider When Choosing a Manufacturing Technique

Choosing the right plastic part manufacturing technique depends on how well the process fits your material, design, and production goals.

Each method comes with strengths and limits, so evaluating the factors menioned below helps you avoid defects, delays, and unnecessary costs.

1. Material Properties

What to do: Check how the polymer behaves during processing, including rigidity, flexibility, heat resistance, and flow. Rigid materials pair well with injection molding or CNC machining, while softer grades that stretch easily align with extrusion or blow molding.

Why do it: Each material responds differently to pressure and temperature, and using a process that does not match its behavior leads to weak parts, poor finish, or dimensional issues.

Polymer Type | Suitable Processes | Key Reason |

ABS | Injection molding, CNC machining | Rigid, holds shape under heat and pressure |

Polypropylene (PP) | Extrusion, Blow molding | Flexible, ideal for hollow parts |

Polycarbonate (PC) | Injection molding, Thermoforming | Heat-resistant, suitable for clear parts |

PET | Blow molding, Extrusion | Good for bottles and continuous profiles |

PVC | Extrusion, Thermoforming | Forms easily into sheets and pipes |

2. Production Volume

What to do: Decide whether you need high-volume output or small batches. Injection molding and blow molding fit large runs, while 3D printing or CNC machining support low-volume work where design changes are frequent.

Why do it: Injection molding and blow molding handle mass production efficiently, while 3D printing or CNC machining support short runs or custom parts. Matching volume avoids overspending on tooling and reduces delays.

3. Part Complexity and Design

What to do: Review how detailed or challenging the geometry is. Thin walls run well in injection molding, hollow shapes form reliably in blow molding, and intricate internal channels build cleanly in 3D printing.

Why do it: Thin walls and repetitive features perform well in injection molding, hollow forms work best in blow molding, and intricate internal channels are suitable for 3D printing. Using the right technique reduces rework and dimensional errors.

4. Cost Considerations

What to do: Compare tooling costs, cycle times, material waste, labor needs, and machine requirements before selecting the method. Processes like injection molding and blow molding need significant tooling, while CNC machining and 3D printing avoid that expense.

Why do it: Understanding where most of the cost comes from helps maintain budget control and ensures the chosen technique delivers reliable output without unnecessary spending.

Also Read: Unique plasticizing system forms basis of new IMM

How Is Quality Controlled and Optimized in Plastic Part Manufacturing?

Strong quality control is essential in plastic part manufacturing. Each step, from material handling to final finishing, affects how stable, accurate, and consistent the parts turn out.

To understand how manufacturers maintain this reliability, it helps to look at the core areas that influence overall quality.

1. Maintaining Part Quality

The first area that shapes quality is process control. Good control helps prevent issues like warping, shrinkage, and surface defects. Stable temperatures, proper cooling, and correct material preparation play a major role in producing reliable parts.

Post-processing steps such as trimming or annealing also help refine the final look and performance.

2. Tooling and Mold Design

Quality is also strongly influenced by the design and condition of the tooling. High-quality molds support consistent plastic manufacturing processes.

A well-built mold allows faster cycle times, clean part release, and better dimensional accuracy.

Features such as gate placement, cooling channels, and venting decide how smoothly production runs. When tooling is designed correctly from the beginning, it reduces long-term defects and delays.

Key Aspect | Why It Matters | Impact on Production |

Mold Quality | Ensures consistent part formation | Better accuracy and fewer defects |

Gate Placement | Controls flow into the cavity | Smooth filling and reduced stress |

Cooling Channels | Helps maintain stable temperatures | Faster cycles and uniform parts |

Venting | Allows trapped air to escape | Cleaner surfaces and fewer imperfections |

Overall Tool Design | Supports long-term efficiency | Lower downtime and predictable output |

3. Automation and Efficiency

Another important factor is the level of automation used during production. Automation improves how plastic parts are produced by bringing steady precision to repetitive tasks.

Robots and automated systems manage material feeding, part removal, and inline inspection with consistent speed.

This reduces errors, lowers labor costs, and helps maintain predictable workflows. Integrating automation into key stages supports stable output and overall efficiency.

Once quality control is optimized, next explore the recent trends in plastic part manufacturing.

Emerging Trends in Plastic Part Manufacturing

New approaches and technologies are reshaping how plastic parts are made. Each trend influences material choice, production speed, and overall part quality.

Here are a few notable emerging trends in plastic parts manufacturing:

1. Sustainability

More manufacturers are moving toward eco-friendly options. Bioplastics, recycled materials, and low-waste production methods are becoming common. These changes help reduce environmental impact while keeping parts strong and reliable.

2. Industry 4.0 & Smart Manufacturing

Smart systems are improving how plastic parts are produced. IoT sensors, AI tools, and data tracking allow real-time monitoring of machines. This leads to fewer errors, better consistency, and smoother production with less downtime.

3. Advances in 3D Printing

3D printing is expanding beyond prototypes. It’s now used for custom, low-volume parts that don’t need molds. Since it can create complex shapes easily, it offers more design freedom and can support traditional plastic manufacturing processes when faster changes or small batches are needed.

How MD Plastics Strengthens Plastic Part Manufacturing Efficiency?

In plastic part manufacturing, controlling residual stress is essential for producing stable, high-quality parts. At MD Plastics, we focus on improving the plasticating stage so your injection molding workflow runs smoother, cleaner, and more predictable from beginning to end.

Our technology is built to improve how the melt is prepared, delivered, monitored, and purged, helping you maintain consistent output across various plastic manufacturing processes.

Whether you're upgrading older machines or planning a fresh installation, our team helps you strengthen your overall production setup.

Here’s what we offer:

Inject-EX™ Plasticating Systems: A patented system that creates a more balanced and uniform melt, leading to better control and part consistency. Works with many existing molding machines.

Posi-Melt™ Multipurpose Screws: A flexible screw design that increases material contact with the barrel surface, supporting better mixing and steady melt quality.

MDP™ Non-Return Valves: Designed to ensure reliable melt delivery, reducing variation and helping maintain uniform shot performance.

Barrel Blitz Universal & Poly Clear Prime Purging Systems: Fast, effective purging solutions that cut downtime, speed up material changeovers, and keep the system cleaner.

Melt-IQ™ System: A real-time melt quality monitoring tool that gives you key data to fine-tune your molding process.

Reach out to us to see how our solutions can help you achieve smoother production and stronger results in your plastic part manufacturing operations.

FAQs

1. What are the most common plastic manufacturing processes?

Plastic manufacturing processes such as injection molding, extrusion, blow molding, and thermoforming are widely used because they provide repeatable quality, tight tolerances, and cost-efficient production for various applications.

2. How do you choose the right process for plastic part manufacturing?

The choice depends on part geometry, required strength, surface finish, production volume, and material type. Matching these factors ensures consistent output and reduces defects during manufacturing.

3. What factors impact the durability of plastic parts during production?

Material selection, melt temperature, cooling rate, and tooling design have the biggest influence. Controlled processing reduces internal stress, improves toughness, and supports long-term performance.

4. How important is tooling in plastic part manufacturing?

Tooling quality directly affects accuracy, part consistency, cycle time, and overall cost. Precision-built molds help avoid warping, uneven shrinkage, and surface defects.

5. What role does quality control play in plastic manufacturing processes?

Quality checks such as visual inspection, dimensional analysis, and stress testing help maintain consistent results, reduce rejects, and ensure the part meets application requirements.

6. Can recycled plastics be used for high-quality part production?

Yes, many plastic manufacturing processes support recycled materials. Proper sorting, cleaning, and compounding help achieve reliable mechanical properties while lowering production costs.