Barrier screws are designed to improve mixing and melting efficiency during polymer extrusion, but even the best screw won’t perform well if your barrel temperature profile is off.

Incorrect temperatures can cause poor material flow, polymer degradation, inconsistent product dimensions, and increased wear on your equipment. Optimizing the barrier screw temperature profile ensures uniform melting, smooth extrusion, and higher-quality output.

It’s not complicated, but it requires careful control of multiple zones, sensors, and cooling systems. Small adjustments can make a big difference in process stability and product consistency.

In this guide, we’ll break down how to optimize barrel temperatures for barrier screws and explain practical steps to get the best results.

Key Takeaways

A proper barrier screw temperature profile prevents polymer degradation, ensures smooth flow, and reduces defects in extruded products.

Multi-zone barrels allow independent temperature control across feed, barrier, and metering sections, forming the foundation for precise thermal management.

Cooling, insulation, and PID control are critical to maintain stable, repeatable temperatures throughout the extrusion process.

Material-specific heat properties must be considered when setting barrel temperatures, especially for heat-sensitive polymers.

Optimized barrel temperatures improve throughput, reduce downtime, and minimize scrap, positively impacting both quality and efficiency.

Understanding Barrier Screw Temperature Profiles: How They Shape Melt Quality

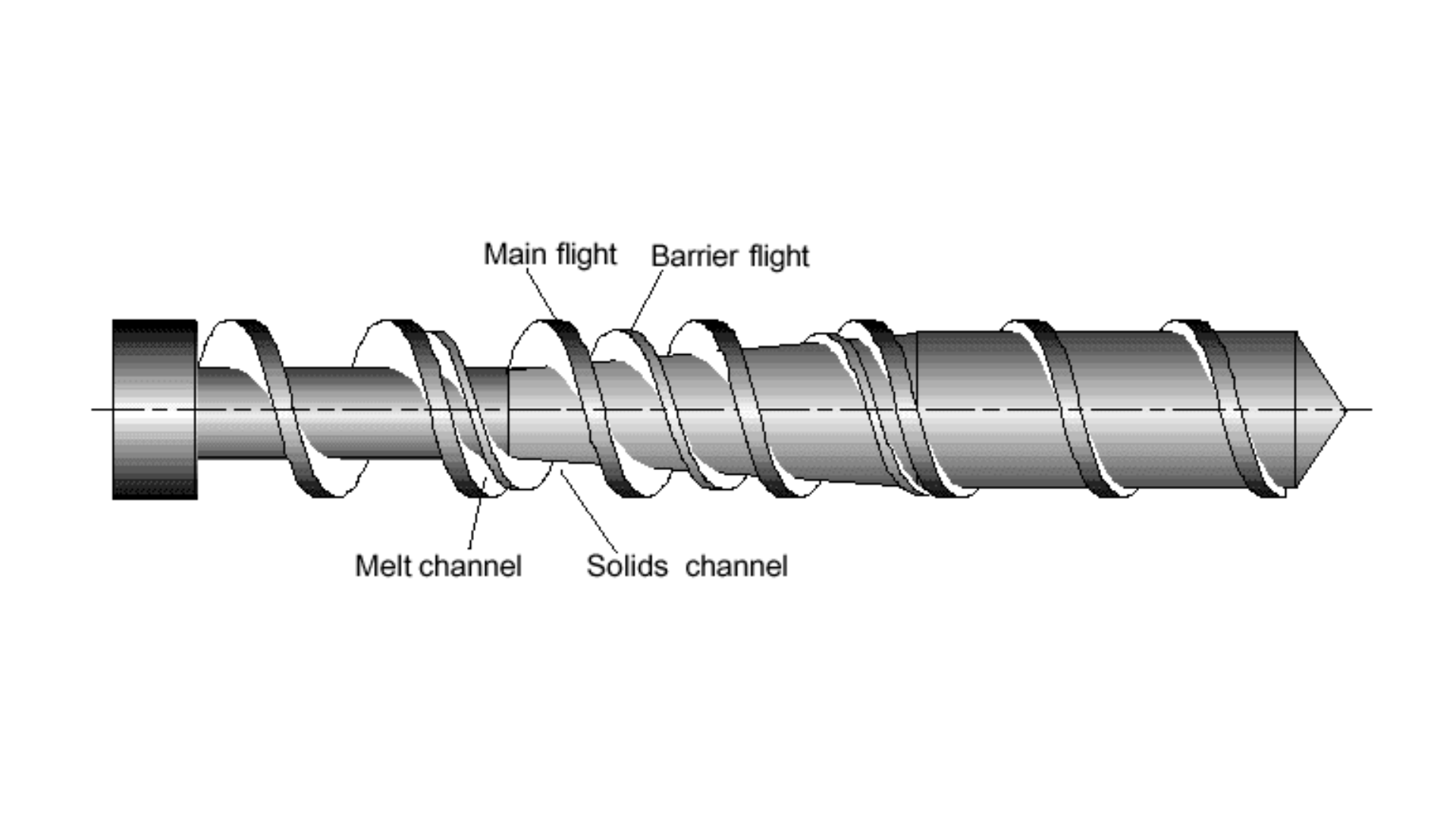

Barrier screw barrels are divided into distinct zones such as feed, barrier, and metering. each responsible for guiding polymer from solid pellets to a fully melted, uniform state.

The process works by carefully raising the polymer temperature as it moves through each zone, with precise control to ensure consistent melting. Cooling can be applied in sensitive areas to prevent overheating, and sensors or PID controllers help maintain stable temperatures throughout.

The typical sequence:

Feed Zone: Introduces polymer pellets and begins gradual heating

Barrier Zone: Separates melt from remaining solids, ensuring complete homogenization

Metering Zone: Pushes fully melted polymer toward the die, ready for shaping

Improper temperatures can cause incomplete melting, uneven flow, discoloration, foaming, or degraded material properties. Each zone requires precise management to ensure uniform melt, consistent part quality, and reliable production.

A well-controlled barrier screw temperature profile ensures smooth polymer flow, consistent melt quality, and predictable, high-quality parts across every production batch.

This is exactly where MD Plastics steps in. With solutions like nject-EX™ Plasticating Systems and Posi-Melt™ Multipurpose Screws for monitoring and purging, MD Plastics enhances barrier screw performance from feed to metering.

Our systems integrate every stage of extrusion to deliver smoother, more uniform, and high-quality parts for all barrier screw applications.

10 Essential Steps to Optimize Your Barrier Screw Temperature Profile

Proper barrel temperature control is the essential for high-quality extrusion and injection molding. Each barrel zone plays a unique role in melting, mixing, and conveying polymer. Optimizing these zones ensures consistent melt, fewer defects, and improved efficiency.

Here’s a detailed look at how to do it:

1. Understand Your Multi-Zone Barrel

The feed, barrier, and metering zones of a barrel are like different gears in a machine, each performs a distinct function. Knowing their purpose allows you to tailor temperatures precisely, preventing partial melting or uneven flow that leads to product defects.

Steps:

Identify each barrel zone and its function.

Verify independent control for precise adjustments.

Observe how polymer transitions from feed to metering.

Example: In PVC extrusion, the feed zone softens pellets, the barrier zone completes melting, and the metering zone ensures smooth delivery to the die.

2. Align Die and Adapter Zones

These exit zones determine the polymer’s final shape and surface quality. Incorrect temperatures here can warp or distort parts, even if upstream melting was perfect. Proper alignment ensures dimensional accuracy and smooth surfaces.

Steps:

Follow resin manufacturer recommendations.

Adjust zone temperatures to maintain uniform flow.

Regularly check dimensions and surface finish.

Example: PET bottle production achieves consistent wall thickness and clarity when die and adapter zones are set correctly.

3. Preheat the Feed Throat

The first touchpoint for polymer pellets, the feed throat, must be carefully managed. Preheating avoids bridging or jamming, reduces screw torque, and prevents early degradation, keeping production smooth.

Steps:

Heat feed throat slightly above ambient.

Monitor for pellet bridging.

Fine-tune for optimal pellet conveyance.

Example: PVC extrusion with preheated feed prevents blockages and reduces stress on the screw.

4. Gradually Increase Temperatures Across Zones

Rapid temperature changes can shock polymers, causing degradation or inconsistent melt. A progressive ramp ensures complete melting while preserving material integrity.

Steps:

Start lower in the feed zone and incrementally increase to the metering zone.

Avoid temperature spikes that may burn the polymer.

Observe melt uniformity before reaching the die.

Example: ABS extrusion: feed 180°C → barrier 220°C → metering 230°C ensures even melting and smooth flow.

5. Use Screw Cooling in the Feed Section

Some polymers are heat-sensitive and may melt prematurely in the feed zone. Cooling prevents early softening, stabilizes solids conveyance, and ensures the barrier section receives a consistent feed.

Steps:

Install cooling channels or jackets in the feed zone.

Adjust based on polymer sensitivity.

Monitor melt stability continuously.

Example: Nylon extrusion benefits from feed section cooling to prevent streaks and bubbles.

6. Employ PID Control for Each Zone

Precise temperature control is essential for reproducible results. PID systems provide feedback loops that maintain stable temperatures, preventing deviations that compromise part quality.

Steps:

Set target temperatures for each zone.

Monitor continuously for deviations.

Adjust PID parameters for different polymers.

Example: PETG extrusion requires ±2°C control to maintain clarity and uniform flow.

7. Place Temperature Sensors Strategically

Accurate data from sensors ensures PID controllers keep zones at their setpoints. Poor placement can give false readings, leading to uneven melt and product inconsistencies.

Steps:

Place thermocouples or RTDs at critical points along the barrel.

Verify sensor accuracy regularly.

Integrate readings into your control system.

Example: Barrier zone sensors in HDPE extrusion confirm complete melting before polymer enters the metering zone.

8. Add Cooling Zones Near the Die

Even if the polymer melts perfectly, it can overheat near the die, causing defects. Localized cooling ensures consistent temperature at the exit, preserving part dimensions and surface finish.

Steps:

Install cooling channels near the die.

Adjust cooling intensity depending on the polymer.

Check final part quality for surface and dimensional consistency.

Example: HDPE pipe extrusion uses die cooling to maintain smooth walls and precise diameter.

9. Adjust for Material-Specific Heat Needs

Every polymer has unique thermal properties. Ignoring these leads to under- or over-melting. Tailoring temperatures ensures complete fusion without degrading the polymer.

Steps:

Review the polymer’s heat capacity and sensitivity.

Adjust zone temperatures and dwell times accordingly.

Test and monitor melt flow and product quality.

Example: Polycarbonate requires slower ramping than polypropylene to prevent bubbles and maintain transparency.

10. Insulate Your Barrel Properly

Even with precise heating, heat loss reduces energy efficiency and destabilizes temperatures. Proper insulation maintains steady conditions, reduces energy costs, and improves overall part consistency.

Steps:

Use high-quality insulation around the barrel.

Inspect regularly for wear or damage.

Adjust heating as necessary to maintain uniformity.

Example: Insulated PVC extrusion barrels keep sheet thickness consistent and reduce energy consumption.

Once your barrel temperatures are properly managed, the advantages become clear.

Also Read: How Do You Monitor Screw and Barrel Wear Effectively?

Key Benefits of Optimizing Barrier Screw Temperature Profiles

A well-optimized barrier screw temperature profile addresses the root cause of many extrusion challenges by ensuring consistent melt quality and flow. The benefits are visible across your production metrics, from reduced scrap to predictable part performance.

It has optimized temperature profile across the main flight, barrier flight, melt channel, and solids channel improves melting efficiency, leading to consistent output quality and reduced material degradation.

Here’s how optimizing barrel temperatures helps your process:

Reduced Scrap: Improper barrel temperatures can lead to polymer degradation, uneven flow, and surface defects. By maintaining the right barrier screw temperature profile, material stress and defects are minimized, lowering scrap rates and material waste.

Improved Yield: Consistent melting and flow ensure uniform part quality. This reduces rejects, improves first-pass yield, and supports reliable production output.

Lower Equipment Wear: Stable temperatures reduce mechanical stress on screws, barrels, and supporting components, extending equipment life and lowering maintenance costs.

Enhanced Throughput: With predictable melt behavior, production can run faster and more efficiently, boosting overall throughput without compromising part quality.

Predictable Product Quality: A controlled barrier screw temperature profile ensures consistent results across batches, minimizing variation and improving part performance and reliability.

With the fundamentals in place, the next step is to focus on how precise temperature control across barrier screw barrels directly impacts part quality.

Improving Part Quality Through Barrel Temperature Control: Challenges and Best Practices

Optimizing barrel temperatures for barrier screws is critical, but several challenges can affect polymer melting, flow, and part quality. The table below outlines common challenges and recommended best practices to maintain consistent performance.

Challenge | Impact on Production | Best Practices |

Uneven Heating Across Zones | Poor melt consistency, flow defects, part warping | Use multi-zone PID temperature controllers and regularly calibrate sensors |

Overheating in Sensitive Sections | Thermal degradation, foaming, discoloration | Apply cooling in feed or barrier sections for heat-sensitive polymers |

Inconsistent Melt Flow | Dimensional errors, weak spots, increased scrap | Monitor polymer viscosity and adjust screw speed or temperature profile accordingly |

Material-Specific Temperature Requirements | Low-quality parts if wrong settings used | Tailor barrel temperature profile to polymer type (e.g., PE, PP, PVC, ABS) |

Residual Stresses in Melt | Internal stresses causing defects after cooling | Gradually ramp temperatures and maintain uniform heat distribution throughout zones |

Equipment Wear from High Temperatures | Increased maintenance, downtime | Maintain consistent temperatures to reduce mechanical stress on screws and barrels |

Lack of Real-Time Monitoring | Delayed detection of issues, inconsistent batches | Use melt monitoring systems like Melt-IQ or Melt-Profiler to track melt quality in real time |

Following these best practices ensures barrier screws operate efficiently, producing consistent melt quality, minimizing defects, and improving throughput.

How MD Plastics Improves Barrier Screw Performance and Part Quality?

Optimizing a barrier screw temperature profile is more than setting the right numbers. Partners like MD Plastics focus on the full extrusion system, ensuring every barrel zone works together for consistent melt quality and reliable production.

1. Engineered Profiles for Consistent Melt

A well-designed barrier screw temperature profile ensures each barrel zone feed, barrier, and metering maintains precise temperatures.

By carefully controlling these zones, the polymer melts evenly and flows predictably, reducing defects such as voids, inconsistent wall thickness, and surface imperfections.

The Result: Optimized profiles improve part consistency, reduce scrap, and allow you to process a wider range of polymers efficiently.

Also know About: Posi-Melt Screw and “MDP” Valve Performance Test

2. Supporting Components for Accurate Flow

Even the best profile needs precise hardware to perform well. Supporting tools from MD Plastics enhance extrusion reliability:

MDP Non-Return Valves for stable shot delivery

Mini-Shut and Posi-Shut nozzles to prevent leakage and backflow

These components work with the temperature profile to maintain steady melt pressure and flow, improving part quality and reducing downtime.

3. Real-Time Monitoring for Process Control

Tools like Melt-Profiler and Melt-IQ give R&D and process teams real-time insight into melt behavior.

By monitoring temperatures and flow in each barrel zone, teams can detect issues early, verify resin performance, and adjust parameters without guesswork.

Together, monitoring tools and optimized profiles transform a standard barrier screw into a high-performance extrusion system.

Conclusion

A barrier screw may seem simple, but every detail from temperature distribution to cooling balance impacts melt quality, part consistency, and cycle time.

Optimizing your barrier screw temperature profile is one of the most effective ways to reduce scrap, stabilize throughput, and achieve predictable production.

If you are dealing with inconsistent melt, warping, or uneven wall thickness, MD Plastics can help. Our experts evaluate your process and design multi-zone temperature profiles and supporting components tailored to your polymer, screw, and performance goals.

Ready to optimize your barrier screw temperature profile and improve melt quality? Contact MD Plastics for a quick engineering consultation.

FAQs

1. What is a barrier screw temperature profile?

A barrier screw temperature profile is the set of temperatures assigned to each barrel zone to ensure proper melting, mixing, and conveyance of polymers during extrusion.

2. Why is multi-zone control important?

Independent control of feed, barrier, and metering zones ensures uniform melting and consistent flow, which prevents defects and improves part quality.

3. Can cooling be applied in barrier screw barrels?

Yes. Cooling in the feed section or near the die prevents overheating, protects heat-sensitive polymers, and maintains dimensional stability.

4. How does a barrier screw temperature profile affect part quality?

Accurate temperature control reduces internal stresses, warping, and surface defects, producing consistent, high-quality plastic parts.

5. Do all polymers use the same barrier screw temperature profile?

No. Each polymer has unique thermal properties. Temperature profiles must be customized to achieve optimal melting, flow, and final part performance.