Poly Clear Prime Purging Compound

- 92% less material usage

- 50% faster color changes

- Advanced surfactant cleaning

US Patent Protected

ISO 9001:2015

Comprehensive plastic process equipment solutions including patented injection molding components, advanced temperature monitoring systems, high-performance screws, and specialized purging compounds. Our innovative technologies optimize melt quality, reduce downtime, and enhance manufacturing efficiency across automotive, medical device, and electronics applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 17 results

What makes MD Plastics' equipment different from standard plastic processing equipment?

Our equipment features patented technologies like Mini-Shut™ automatic shutoff and Posi-Melt™ screws that deliver superior melt quality and reduced downtime.

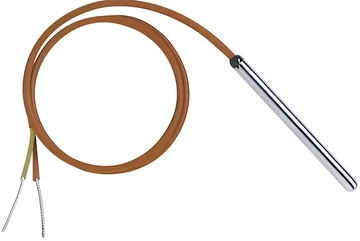

How accurate are your temperature monitoring systems?

Can your equipment work with existing injection molding machines?

What is the typical service life of your plasticating components?

Do you provide technical support for installation and optimization?

What industries benefit most from your plastic processing solutions?

How do your purging compounds reduce material waste?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components for automotive applications requiring consistent quality and durability

Sterile plastic components and precision molding equipment for critical medical device applications

High-quality plastic housing components and precision parts for electronic devices and assemblies

Heavy-duty plastic processing equipment and components for demanding industrial manufacturing environments

Talk to our experts for custom solutions and tailored guidance.

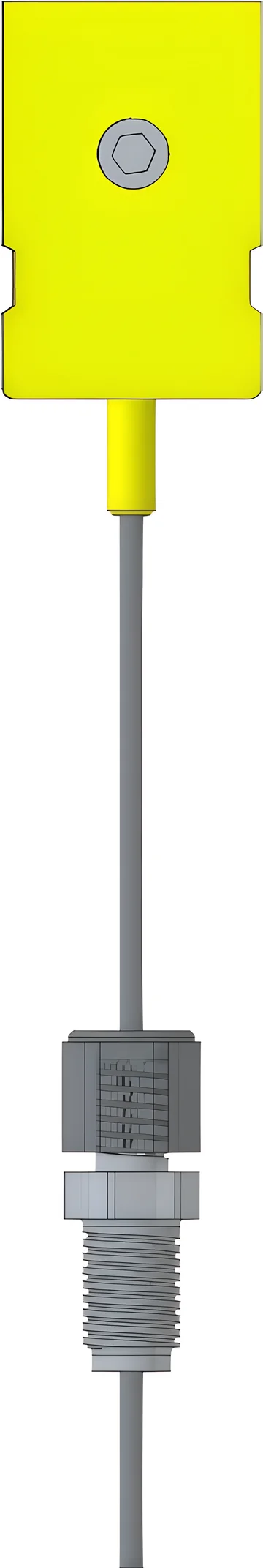

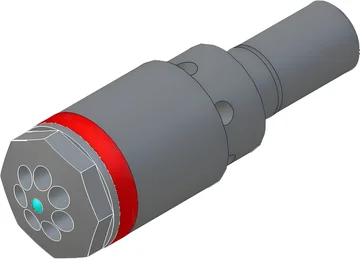

Eight patents in plasticating technologies including Mini-Shut™, Posi-Melt™, and Inject-EX™ systems delivering proven performance improvements across all applications.

Founded by Mike Durina with 40+ years experience, combining deep industry knowledge with cutting-edge design tools for optimal plasticating solutions.

From temperature sensors to mixing screws, providing end-to-end equipment solutions that optimize melt quality, reduce downtime, and enhance profitability.

Connect with our technical team for custom solutions and application-specific recommendations. Fast response guaranteed.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com