Posi-Melt™ Plasticating Screws

Custom-designed screws with precision-engineered segments for optimal melt quality, material flow, and mixing performance tailored to your specific application.

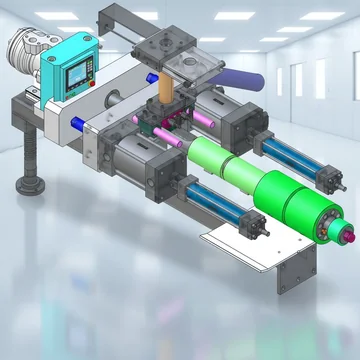

Transform your injection molding operations with MD Plastics' innovative custom solutions. Our patented Posi-Melt™ screws, Inject-EX™ systems, and precision-engineered components deliver superior melt quality, increased productivity, and reduced downtime. Partner with industry leaders who understand your unique challenges and engineer solutions that drive profitability.

Comprehensive solutions from custom screw designs to complete melt delivery systems.

Custom-designed screws with precision-engineered segments for optimal melt quality, material flow, and mixing performance tailored to your specific application.

Revolutionary non-reciprocating screw technology with integrated plunger design for superior process control and consistent melt density monitoring.

High-performance valves engineered for 58% improved shot consistency, 20% reduced cycle time, and extended maintenance intervals.

Expert partnership for material behavior assessment, process troubleshooting, and system redesign to optimize your molding operations.

Tailored screw designs with intensive process analysis, advanced surface treatments, and proprietary coatings for maximum wear resistance.

Proprietary temperature measurement technology for precise process control, reduced variability, and repeatable results in critical applications.

At MD Plastics, we don't believe in one-size-fits-all solutions. Our engineering team carefully analyzes your operations, machines, materials, and objectives to deliver custom injection molding technologies that maximize your profitability. From patented Posi-Melt™ screws to complete Inject-EX™ systems, every component is precision-engineered for your specific application needs.

Proven results with leading manufacturers worldwide including Foxconn, Boston Scientific, and TE Connectivity.

25 years of innovation and excellence in injection molding technologies.

Eight patents including revolutionary Inject-EX™ and Melt-Profiler™ technologies for superior performance.

Never one-size-fits-all - every solution is precision-engineered for your specific materials and objectives.

25+ years of plasticating experience with proven results across medical, automotive, and electronics sectors.

Complete partnership from initial consultation through design, manufacturing, testing, and ongoing follow-up support.

Industry leaders with decades of plasticating experience.

Founder

Mike Durina brings unparalleled expertise to injection molding technologies with an AAS in Plastic Engineering from Ferris State University and a BS in Industrial Engineering from Kent State University. His career began in 1978 across three injection molding firms before joining Spirex in 1984, where he served as VP of Sales & Service for 16 years. Under his leadership, Mike transformed Spirex from $1.8 million in sales with 18 employees to $22 million with 180 employees. In 1999, he founded MD Plastics Inc. with a vision to advance plasticating technologies. Mike holds eight patents with one pending, including innovations like the Melt-Profiler™, Inject-EX™, Mini-Shut™, and MDP™ Performance Valve. His deep understanding of the plasticating process drives MD Plastics' commitment to helping injection molders achieve greater profitability through better technology.

What makes MD Plastics' injection molding solutions different?

Our solutions are never one-size-fits-all. We analyze your specific operations, machines, materials, and objectives to provide custom-engineered components. With eight patents including revolutionary technologies like Inject-EX™ and Melt-Profiler™, we deliver measurable improvements in melt quality, productivity, and profitability.

How do Posi-Melt™ screws improve molding performance?

What results can I expect from MDP™ Non-Return Valves?

Do you provide support for existing equipment modifications?

How does the Inject-EX™ system differ from traditional reciprocating screws?

What industries benefit most from your technologies?

How long does custom screw design and manufacturing take?

Do you offer training and ongoing technical support?

Connect with our engineering experts for a custom solution consultation.

Revolutionary plasticating and injection molding system technology.

Automatic shutoff nozzle tip eliminating drooling and strings.

Precise control non-return valve for superior consistency.

Connect with our engineering team to discuss how our patented technologies can optimize your operations and increase profitability.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com