Custom Screw Design

Precision-engineered Posi-Melt™ plasticating screws tailored to your specific materials and applications for optimal melting and mixing performance.

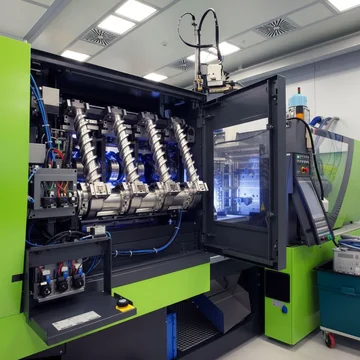

Transform your injection molding operations with MD Plastics' innovative plasticating components and cutting-edge technologies. Our custom-engineered solutions deliver improved melt quality, increased productivity, and reduced scrap rates while extending equipment life. From patented Posi-Melt™ screws to revolutionary Inject-EX™ systems, we optimize your entire plastic processing workflow for maximum profitability and operational excellence.

Comprehensive plasticating components and technologies designed to maximize your injection molding profitability.

Precision-engineered Posi-Melt™ plasticating screws tailored to your specific materials and applications for optimal melting and mixing performance.

Revolutionary injection molding technology with non-reciprocating screw design that improves melt quality and enables advanced process monitoring.

MDP™ Performance and Posi-Shut™ valves engineered to improve shot-to-shot consistency and extend mold maintenance intervals.

Melt-Profiler™ and Melt-IQ™ systems provide real-time temperature monitoring and process control for consistent, repeatable results.

LSR conversions, vented barrel modifications, and injection unit resizing to expand your processing capabilities without new equipment.

Expert engineering support for material behavior analysis, process troubleshooting, and system redesign to improve overall performance.

Initial Process Assessment and Consultation

Our engineers conduct intensive data gathering relative to your current process, machine specifications, materials, and production objectives to identify optimization opportunities and establish baseline performance metrics.

Custom Design and Mathematical Modeling

Precision Manufacturing with Advanced Materials

Installation, Testing and Performance Tuning

Ongoing Support and Performance Monitoring

Transforming injection molding operations with measurable improvements in consistency, cycle time, and maintenance efficiency.

Over two decades of plasticating innovation delivering measurable results for injection molders worldwide.

Eight patents including revolutionary Inject-EX™, Melt-Profiler™, and Mini-Shut™ innovations that solve real manufacturing challenges.

Never one-size-fits-all solutions - every component is precisely engineered using proprietary software for your specific application needs.

Documented results including 58% improved shot consistency, 20% cycle time reduction, and 30% extended maintenance intervals.

End-to-end engineering support from initial consultation through installation, testing, and ongoing performance optimization for sustained results.

Industry experts with decades of plasticating experience.

Founder

Mike Durina brings over four decades of plastics industry expertise to MD Plastics Inc. He holds an AAS in Plastic Engineering from Ferris State University and a BS in Industrial Engineering from Kent State University. His career began in 1978 with three separate injection molding firms before joining Spirex in 1984. As VP of Sales & Service at Spirex, Mike demonstrated exceptional leadership, growing company sales from $1.8 million with 18 employees to $22 million with 180 employees over 16 years. In 1999, he founded MD Plastics Inc. to advance plasticating technologies and help injection molders achieve greater profitability. Mike's innovative mindset has resulted in eight awarded patents with one pending, including breakthrough technologies like the Melt-Profiler™, Inject-EX™, Mini-Shut™, and MDP™ Performance Valve that have revolutionized the injection molding industry.

What makes MD Plastics' screw designs different from standard screws?

Our Posi-Melt™ screws are never one-size-fits-all. Each screw is custom-designed using proprietary software that analyzes your specific materials, machine parameters, and production goals. We calculate precise compression ratios, channel depths, pitch geometry, and incorporate advanced mixing elements like XLA mixers or MB barrier flights for superior melt quality.

How does the Inject-EX™ system improve upon traditional reciprocating screw technology?

What kind of performance improvements can I expect from MD Plastics components?

Do you provide support for installation and optimization?

Can you convert existing equipment rather than requiring new machines?

What materials and surface treatments do you use for durability?

How do your process monitoring systems work?

What is your typical project timeline from consultation to implementation?

Contact our engineering team for a comprehensive consultation and performance assessment.

Revolutionary plasticating and injection molding system technology

Miniature automatic shutoff nozzle tip innovation

Advanced plasticating screw for efficient polymer processing

Get expert consultation on optimizing your injection molding performance with our proven plasticating solutions.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com