Real-Time Process Monitoring

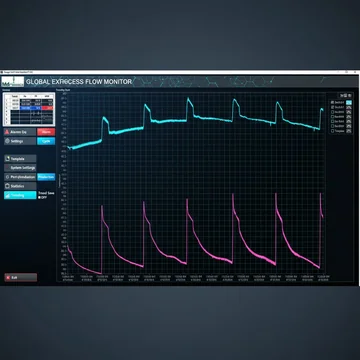

Advanced monitoring capabilities that track temperature, pressure, and flow rates in real-time, providing instant feedback for optimal process control and quality assurance.

Transform your extrusion operations with MELTIQ's cutting-edge process management software. Our advanced platform integrates seamlessly with your existing equipment to optimize material flow, reduce waste, and maximize productivity through real-time monitoring and intelligent control systems designed for modern manufacturing environments.

Comprehensive software tools designed to optimize every aspect of your extrusion process management.

Advanced monitoring capabilities that track temperature, pressure, and flow rates in real-time, providing instant feedback for optimal process control and quality assurance.

Smart automation features that adjust process parameters automatically based on material characteristics and production requirements, ensuring consistent output quality.

Machine learning algorithms that analyze historical data to predict potential issues, optimize maintenance schedules, and prevent costly downtime before problems occur.

Advanced algorithms that optimize material usage, reduce waste, and improve product quality by analyzing material behavior and process conditions continuously.

Comprehensive quality management tools that integrate with existing systems to ensure consistent product quality and compliance with industry standards.

Detailed analytics and reporting capabilities that provide insights into production efficiency, material usage, and overall equipment effectiveness for data-driven decisions.

MELTIQ represents the next generation of extrusion process management software, combining decades of industry expertise with cutting-edge technology. Our platform provides unprecedented visibility into your manufacturing processes, enabling precise control over temperature profiles, material flow, and quality parameters to maximize efficiency and profitability.

Discover how leading manufacturers achieve exceptional results with MELTIQ software solutions.

Experience the MD Plastics difference with our revolutionary process management technology.

Patented technology backed by 25 years of plastics engineering expertise and continuous R&D investment.

Seamless compatibility with existing equipment and manufacturing systems for effortless implementation and operation.

Advanced AI-driven analytics provide actionable insights for optimizing performance and preventing costly production issues.

Comprehensive technical support and training from our team of experienced plastics engineering professionals.

Leading experts in plastics engineering and software development.

Founder

Mike Durina brings unparalleled expertise to MELTIQ software development with an AAS in Plastic Engineering from Ferris State University and a BS in Industrial Engineering from Kent State University. Since founding MD Plastics Inc. in 1999, Mike has revolutionized the plastics industry with eight awarded patents and one pending. His 16-year tenure at Spirex, where he grew sales from $1.8 million to $22 million as VP of Sales & Service, provided the foundation for understanding real-world manufacturing challenges. Under his leadership, MD Plastics has developed groundbreaking technologies including the Melt Profiler™ and Inject-EX™ systems that form the technological backbone of MELTIQ's advanced process management capabilities.

What is MELTIQ software and how does it work?

MELTIQ is an advanced process management software that integrates with extrusion equipment to provide real-time monitoring, intelligent control, and predictive analytics. It uses proprietary algorithms to optimize material flow, temperature profiles, and quality parameters automatically.

Is MELTIQ compatible with existing extrusion equipment?

What kind of ROI can I expect from implementing MELTIQ?

Do you provide training and support for MELTIQ software?

How does MELTIQ handle data security and compliance?

Can MELTIQ integrate with our existing quality management systems?

What ongoing maintenance does MELTIQ software require?

How quickly can MELTIQ be implemented in our facility?

Connect with our software specialists for a personalized MELTIQ demonstration.

Industry-leading innovation in plastics processing technology

Meeting international standards for quality management

Trusted by Fortune 500 manufacturing companies worldwide

Contact our team to schedule a personalized MELTIQ demonstration and discover how our software can transform your manufacturing operations.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com