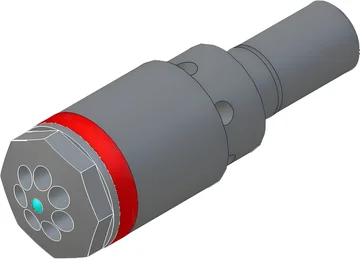

Inject-EX™ Plasticating System

- Stationary screw eliminates deficiencies

- Ultra precise shot control mechanism

- Real-time melt density verification

Patented Technology

Advanced plastic injection molding machines and plasticating systems designed for precision manufacturing. Our innovative Inject-EX™ technology delivers superior melt quality, precise shot control, and enhanced productivity for thermoplastics and LSR processing applications across automotive, medical, and industrial sectors.

What makes the Inject-EX™ system different from traditional injection molding machines?

Revolutionary stationary screw design eliminates reciprocating screw deficiencies for superior melt quality and precise shot control.

Can the Inject-EX™ system be retrofitted to existing injection molding machines?

What materials are compatible with your injection molding systems?

What technical support is available after installation?

What machine size ranges does the Inject-EX™ system accommodate?

How does the Temp-Sense™ Melt Sensor improve quality control?

Is global shipping available for injection molding equipment?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components for automotive suppliers requiring consistent quality and reliability

Sterile plastic components and precision molding for medical devices with strict quality standards

Plastic housing components and precision parts for electronics manufacturers requiring tight tolerances

Heavy-duty plastic processing for industrial facilities requiring superior material handling capabilities

Talk to our experts for custom solutions and tailored guidance.

Decades of proven expertise in plasticating technology with innovative patented solutions for enhanced productivity and quality.

Exclusive Inject-EX™ system with stationary screw design delivers superior melt quality and precise shot control for consistent results.

Personal consultation with founder Mike Durina for custom system design and comprehensive technical support throughout your project.

Connect with our technical team for custom system design, retrofit solutions, and comprehensive support for your manufacturing requirements.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com