Running a molding machine gets difficult when drool, stringing, or an unstable cushion keeps pushing your scrap rate above target. These issues not only waste material, but they also consume maintenance hours and disrupt planned throughput.

Report Linker forecasts show that US plastic exports alone are projected to reach around $80.5 billion by 2028. In that context, every lost cycle due to melt leakage or freeze-off raises your cost per unit and hurts overall equipment effectiveness.

If you often adjust temperatures or clean the mold face, the nozzle may be the source of melt issues, and you are not alone in facing the problem.

This guide answers questions like "how many types of nozzle in injection molding machine" and "injection plasticizing nozzle." It helps you compare nozzle types, align them with your resin and KPIs, and decide when a shut-off or engineered design is worth adopting.

Key Takeaways

Most machines rely on two core nozzle families: fixed (open) nozzles and shut-off (automatic) nozzles.

Nozzle choice can directly improve scrap rate, cost per unit, throughput, and lead time stability.

Specialized designs, such as mixing, filtering, and modular nozzles, solve color, contamination, and maintenance problems.

Nozzles work as part of a full plasticating system with the screw, barrel, and check valve, not as isolated parts.

A simple selection checklist and maintenance checklist can help teams reduce downtime and supplier risk.

What Is an Injection Molding Nozzle and Why Does It Matter?

An injection molding nozzle is the component at the end of the barrel that seals against the mold sprue. It provides the final flow path for the molten plastic as it enters the mold.

Before comparing varieties, it helps to ground the nozzle's basic role in the plasticating system.

The nozzle is the final channel the melt passes through before entering the cold mold. Small design choices here can have a significant effect on melt quality and process stability.

1. What is the Nozzle's Role in Melt Delivery

The nozzle sits between the barrel and the mold's sprue bushing. It performs three core functions:

Sealing the system: It holds pressure and keeps the molten plastic inside the barrel until injection starts.

Directing the melt: It directs the melt into the sprue bushing at the required flow rate and velocity profile.

Supporting temperature control: It helps maintain the correct melt temperature at the last point before the plastic enters the mold cavity.

If the nozzle leaks, freezes off, or runs at the wrong temperature, you see the impact immediately in scrap rate, cycle time, and unplanned downtime.

2. The Two Main Families of Nozzles

If you are asking "how many types of nozzle in injection molding machine are commonly used," most machine-side nozzles fall into two prominent design families:

Nozzle Type | Primary Function | Best Use Case | Primary Operational Risk |

Fixed (Open) Nozzle | Simple flow channel, basic seal | Higher-viscosity resins are general-purpose work | Stringing, drooling, and material leakage |

Shut-Off (Automatic) | Mechanical gate to close the melt path | Sensitive or lower-viscosity resins, higher precision | More complex internals, added maintenance |

You can then build extra functions on top of these families, such as mixing or filtering, which we will cover later.

1. The Fixed Nozzle

The fixed (open) nozzle is the most common variety on many older or general-purpose machines. It has no moving parts and is attractive when simplicity and low maintenance are the main requirements.

Understanding the Straight-Through Design

A fixed nozzle is essentially a tapered tube attached to the machine barrel. It mates against the mold sprue bushing and provides a clear path for the melt.

In practice, it works like this:

Continuous flow path: The melt flows straight through, with no shut-off pin or valve inside the nozzle body.

Sprue seal by freezing: After injection, the mold cools the sprue region. A small plug of solidified plastic blocks further slows the flow until the next cycle. In cold-runner molds, the sprue face typically creates a small freeze plug. In hot-runner or insulated systems, sealing is achieved by pressure balance, not freezing.

Simple heat control: With no internal mechanisms, it is easier to heat and control. Many commodity resins run well under this arrangement.

When to Use an Open Nozzle

The fixed nozzle is not ideal for every resin or mold. It works when the leakage risk is low. Use a fixed nozzle when most of these apply:

Relatively viscous materials: You run resins such as polypropylene (PP) or polyethylene (PE) that are less likely to leak at your normal temperature and pressure settings.

Temperature-sensitive resins: Your material may degrade if it sits near a shut-off pin or complex internal parts for too long.

Shortest possible cycle time: You need minimal additional actuation time in the cycle, and a simple nozzle helps keep injection time tight.

Low maintenance preference: You want fewer moving parts to inspect and rebuild, and you accept some risk of drool in exchange.

If you notice drool, stringing, or weight variation, your process may require more control than an open nozzle can provide.

2. The Shut-Off Nozzle: For Melt Control and Shot Stability

When drool, stringing, or cushion variation raises scrap, an automatic shut-off nozzle is a practical upgrade. It opens during injection and closes between cycles to seal the melt path.

How the Automatic Shut-Off Helps the Process

A shut-off nozzle improves melt control and KPI performance in several ways:

Reduces drool and stringing by closing the melt channel between cycles, helping lower scrap and keep the mold face clean.

Improves shot consistency because the melt does not escape, giving the screw steadier back pressure and more stable part weight.

Supports higher back pressure, allowing better mixing without losing material at the tip.

Protects cosmetic surfaces by preventing leakage that can cause flash or surface defects.

These improvements influence cost per unit, yield, and unplanned downtime.

Note: A shut-off nozzle may reduce scrap rate by minimizing drool and stringing, helping lower cost per unit through less material waste and rework.

Common Shut-Off Mechanisms

Shut-off nozzles use several actuation methods. The mechanism affects complexity, reliability, and maintenance load.

Mechanism Type | How It Works | Best Used For | Key Considerations |

Spring-loaded | Spring holds a pin or ball closed. Melt pressure opens it. | Small to mid-size machines, general duty | Simple, but springs can fatigue over time. |

Pneumatic/hydraulic | External cylinder drives a pin or sleeve open or closed. | Larger machines, high-speed applications | Requires external plumbing and control |

Melt-pressure assisted | Melt pressure itself helps keep the tip in the closed seat until injection. | Sensitive or higher-value resins, precision work | Fewer external parts, cleaner layout. |

Melt-pressure-assisted designs use melt pressure to control shut-off. This reduces external hardware and lowers supplier risk by limiting actuated parts.

Also Read: How Do You Monitor Screw and Barrel Wear Effectively?

3. Specialized Nozzle Functions: Mixing, Filtering, and Modularity

Once you have chosen between fixed or shut-off behavior, you can add specialized features to solve color, contamination, or maintenance problems. These options are common in higher-mix or higher-value plants.

1. Mixing Nozzles

Mixing nozzles incorporate internal elements that repeatedly divide and recombine the melt. Mixing nozzles increase residence time and shear, so avoid them for heat-sensitive resins

Primary function

Promote color and additive uniformity

Improve the melt temperature balance near the gate

Benefits

Fewer color streaks in cosmetic parts

Better additive distribution

More consistent properties across cavities

Risks and trade-offs

Increased pressure drop, which can require higher injection pressure

Greater risk of hang-up if purging is not done correctly

2. Gap-Filter and Screen-Pack Nozzles

Gap-filter and screen-pack designs add internal restriction to catch solid particles and unmelted pellets.

Primary function

Protect fine gates and core pins from hard contamination

Benefits

Proper when running higher levels of regrind

Reduces the risk of tool damage and blocked cavities

Risks and trade-offs

Premature blockage can cause short shots and pressure spikes

Excess shear at tight passages can increase local melt temperature. Avoid filter nozzles with shear-sensitive resins (PVC, POM, PC, PLA), as tight passages can cause thermal degradation.

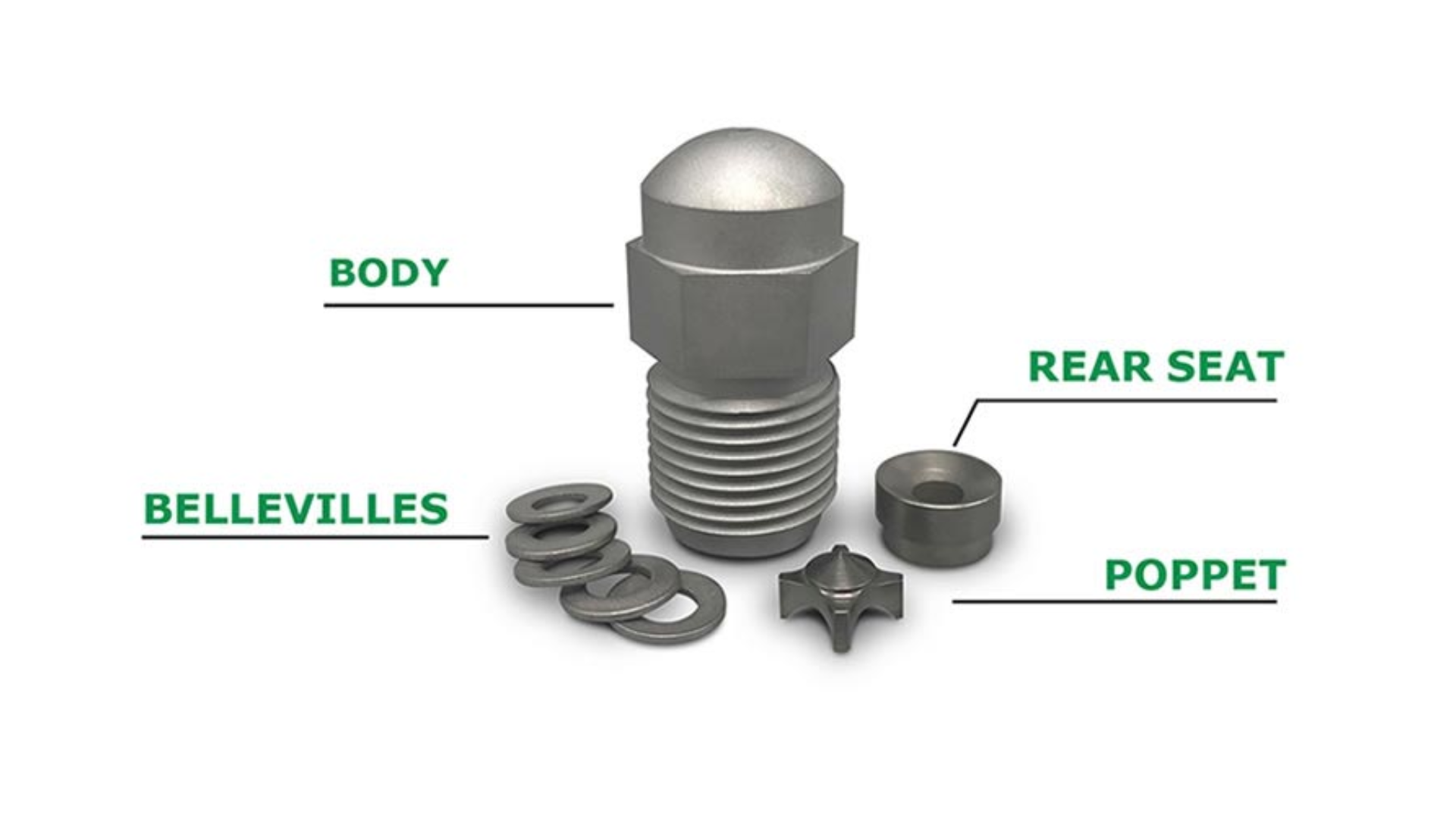

3. Modular Nozzle Designs

Modular designs use a body, tip holder, and interchangeable tips.

Primary function

Make wear parts easier and cheaper to replace

Adapt geometry quickly to different molds

Benefits

Replace only the tip instead of the entire nozzle

Match the tip radius to different sprue bushings with less downtime

Risks and trade-offs

Reassembly requires care and correct torque

Misalignment between sections can cause leakage and pressure loss

These options improve flexibility and long-term cost per unit, but they also create new quality checkpoints, which we address later through a maintenance checklist.

Why Nozzle Choice Matters for Your KPIs

The nozzle is not only a spare part, but it is a point of direct influence on your core KPIs: scrap rate, cost per unit, downtime, throughput, yield, and lead time stability.

1. Decision Checklist: Matching Nozzle to Material and KPIs

For process and R&D engineers, nozzle selection starts with the resin and ends with the numbers. Use this checklist when deciding if you should move from a fixed nozzle to an engineered shut-off or specialized design.

Nozzle Selection Checklist

Is scrap rate above target due to drool or stringing? [Yes/No]

Does your resin type increase unit cost when leakages occur? [Yes/No]

Are cosmetic defects impacting yield? [Yes/No]

Is shot stability outside acceptable variation? [Yes/No]

Does nozzle issue affect throughput or downtime? [Yes/No]

If you answer "Yes" to 2 or more, consider a shut-off or specialized nozzle.

2. Nozzle Wear, Downtime, and Supplier Risk

Nozzles see wear at the tip and at internal sealing surfaces, especially with glass- or mineral-filled resins. Wear shows up as:

Poor sealing against the sprue bushing

Higher leakage and pressure loss

Sticking pins in shut-off designs

Using durable nozzle materials, maintaining them regularly, and working with an engineering-focused supplier helps lower supplier risk and improve uptime.

Nozzle Maintenance Checklist

Inspect nozzle tip and seal weekly.

Clean and purge before material changes.

Check shut-off pins for wear monthly.

Monitor melt temperature at the nozzle tip regularly.

With this foundation, it becomes easier to define what a high-quality nozzle should deliver.

Characteristics of a Top Quality Nozzle

A well-designed injection molding nozzle typically includes these traits:

Even heat across its working length

Minimal dead spots

A consistent seal with the sprue bushing

Metallurgy suited to your resin and fillers

Easy access for cleaning and inspection

With hot runners, tip geometry and heat control become critical because freeze-off or overheating can affect multiple cavities. At this stage, the nozzle is part of the full plasticating system, not a standalone component.

Integrating the Nozzle into the Full Plasticating System

The nozzle does not work alone. Its behavior interacts with the screw, barrel, and check valve.

Precision Tips and Flow Control

For engineering-focused partners, the nozzle is the final quality checkpoint before the mold. Mini-Shut™ and Posi-Shut™ tips are designed for consistent shut-off and smooth flow, especially when matched with the correct screw and valve.

Used in the proper application, these features can:

Reduce drool and improve shot repeatability

Support quick material changeovers by reducing dead spots

Extend tip life when combined with suitable alloys for abrasive resins

You can learn more from the Automatic Shut-Off Nozzles section.

Also Read: Unique plasticizing system forms basis of new IMM

System Synergy with Check Valves and Melt Monitoring

Nozzle performance depends heavily on the non-return valve at the front of the screw. If the valve leaks, pressure at the nozzle will vary, even when the nozzle is in good condition.

For engineers focused on throughput and lead time stability, it helps to view this as a full melt system:

A precision non-return valve, such as the MDP™ Valve, stabilizes metering pressure.

A high-quality nozzle tip provides the final seal and flow pattern.

Melt monitoring tools like Melt-Profiler™ give live data on melt conditions.

Together, these elements help control scrap rate, unit cost, and on-time delivery KPIs. Sustaining these results requires managing nozzle wear and operational risk.

You can learn more by viisting the service page here.

Common Defects and Troubleshooting Related to the Nozzle

Many issues that are blamed on the mold or screw begin at the nozzle. Having a short, practical troubleshooting list helps maintenance and production teams respond faster.

Defect | Likely Cause | Corrective Action |

Drool / Stringing | Melt too fluid for a fixed nozzle, or the shut-off is not sealing. | Lower nozzle temperature, inspect shut-off pin, or switch to a shut-off nozzle. |

Freeze-Off | Nozzle tip temperature too low or long dwell time. | Raise nozzle heat, check the thermocouple, or use a tip with higher melt volume. |

External Leakage at Sprue | Tip radius mismatch or worn tip. | Stop the machine, check alignment, and inspect the radius before restarting. |

Short Shots | Blocked filter, degraded material, or uneven melt flow. | Clean nozzle, inspect filters, and verify melt temperature. |

Pressure Loss / Inconsistent Cushion | Wear in the tip or check valve, or partial blockage. | Inspect wear areas, purge thoroughly, and confirm check valve function. |

Note: Addressing nozzle defects directly impacts key metrics, like fixing drool cuts, scrap rate, and unit cost.

Tips for Servicing Modular and Gap-Filter Nozzles

Servicing these nozzles takes care of their internal paths as they can trap degraded material. Poor cleaning often leads to black specks, pressure loss, and short shots.

1. Cleaning Gap-Filter Nozzles

Gap-filter nozzles use screens or narrow passages to catch debris. Keep them clean with these steps:

Disassemble thoroughly: The filter cannot be adequately cleaned while inside the nozzle body.

Use soft tools: Brass brushes or copper rods remove residue without scratching metal surfaces.

Use heat cleaning when needed: A solvent-free cleaning oven is the safest way to remove heavy buildup without harming the metal.

2. Cleaning Modular Nozzles

Modular nozzles have more parts, so precision matters during cleaning and reassembly.

Inspect the shut-off pin: Look for wear or carbon buildup that could cause sticking.

Clean threads carefully: Removing old plastic prevents misalignment and external leaks.

Soften stubborn materials: For high-temperature resins, pre-soak parts in an approved solvent or use a low-temperature furnace cycle to make residue brittle.

Bottom Line

The nozzle may be small, but it directly affects melt control, scrap rate, and cost per unit. Knowing how many types of nozzle in injection molding machine suit your process, choosing well, and maintaining routinely helps lower scrap and improve uptime.

For challenging resins or higher-value parts, treating the nozzle as a strategic component might improve throughput and yield. If recurring drool, stringing, or nozzle-related downtime is affecting your line, partners like MD Plastics can review your setup and recommend nozzle, valve, and melt-monitoring options.

If improving nozzle performance should be simple, start by visiting MD Plastics for engineering-driven upgrade options.

FAQs

1. What does an injection plasticizing nozzle do?

It stabilizes melt flow between the barrel and mold, supporting consistent plasticizing, metering, and shot delivery for better part quality.

2. When should you switch from a fixed nozzle to a shut-off nozzle?

Upgrade when scrap rises, melt leakage affects part quality, or low-viscosity materials cause inconsistent shot weights.

3. How can you extend nozzle tip life?

Use wear-resistant alloys, maintain correct alignment, and purge regularly to prevent buildup and premature wear.

4. Which injection molding nozzle works best for high-precision applications?

A melt-pressure-assisted shut-off nozzle offers stable sealing, tighter melt control, and more consistent shot performance.