Plastic parts fail for all sorts of reasons, but one of the most preventable is residual stress. These internal tensions get locked into the material during molding, extrusion, or machining.

Left untreated, they can lead to warping, cracking, and premature failure. Annealing is a thermal treatment that eliminates these stresses by giving polymer chains the energy to relax and reorganize.

It's not complicated, but it does require precision. Too much heat and you deform the part. Too little and you waste time without solving the problem.

If you're sourcing plastic components or running production lines, this process directly impacts your quality metrics.

In this article, we’ll break down the plastic annealing process and explore how you can use it to improve your operations.

Key Takeaways:

Residual stress is a primary cause of plastic part failure, leading to warping, cracking, and reduced performance if left unaddressed. Annealing is essential to eliminating these stresses.

Annealing significantly reduces scrap and improves yield by ensuring consistent material properties, enhancing part quality, and optimizing throughput.

Precision in temperature, hold time, and cooling rates is critical for effective annealing; too much heat causes deformation, while too little doesn’t relieve stress properly.

Energy efficiency is a growing focus in annealing, with innovations like heat recovery systems and optimized process controls helping to reduce environmental impact and operating costs.

Annealing plays a key role in integrating with other manufacturing processes such as injection molding, extrusion, and 3D printing, improving stability and minimizing defects across the entire production workflow.

How Does Plastic Annealing Work? A Simple Overview

Annealing is a controlled heat treatment that removes internal stresses from plastic parts after they've been molded, machined, or formed.

The process works by heating the component to a specific temperature range where the polymer chains become mobile enough to relax and reorganize. You hold it at that temperature for a set duration, then cool it gradually under controlled conditions.

The basic sequence:

Heat the part to below its glass transition temperature or melting point

Maintain that temperature long enough for stress relief

Cool slowly to prevent new stresses from forming

During manufacturing, plastic undergoes rapid cooling, mechanical deformation, or uneven pressure distribution. These create frozen-in molecular tensions that remain locked in the finished part.

Without annealing, these stresses cause dimensional changes over time, premature cracking under load, and reduced impact resistance. Parts may pass initial inspection but fail during assembly or in service.

This treatment is particularly critical for machined components, welded assemblies, and thick-walled parts, where stress concentrations are highest. Very thick sections may require multi-stage or extended cycles and may never reach full relaxation.

Common materials that benefit from annealing:

Acetal (POM)

Polycarbonate (PC)

Nylon (PA)

PTFE

Acrylic (PMMA)

PVC

Each of these materials benefits from annealing by improving its physical properties, reducing defects, and increasing its suitability for different applications.

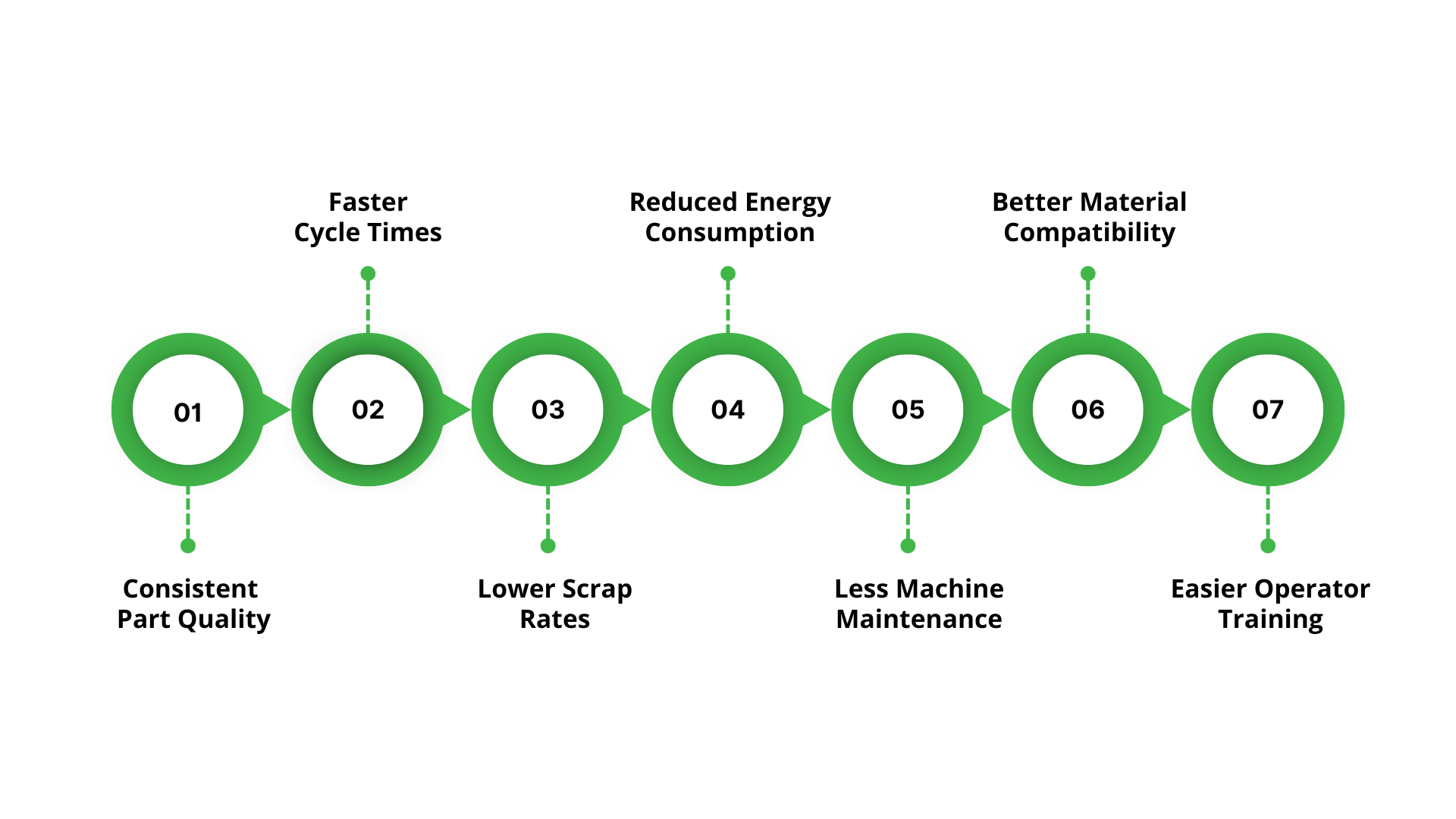

Key Benefits of Annealing Plastic for Quality Improvement

Annealing addresses the root cause of many plastic component failures by eliminating internal stresses that compromise performance. The benefits show up across your quality metrics, from first-pass yield to warranty claims.

Here’s how plastic annealing helps your production process:

Reduced Scrap: Plastic production and waste have doubled between 2000 and 2019. If current trends continue, the amount of plastic produced and discarded could triple by 2060, posing significant challenges for the industry. By minimizing internal stresses, annealed plastic is less likely to warp or crack, reducing material waste.

Improves Yield: Better material consistency means fewer rejects and higher product quality, directly impacting your yield rate.

Enhanced Equipment Uptime: Less stress on machinery due to more stable materials reduces wear and tear on production equipment, leading to increased uptime.

Optimized Throughput: With more reliable materials, production speeds can be optimized, leading to higher throughput.

Reduced Downtime: Fewer material defects and failures during production lead to reduced downtime for repairs and adjustments.

How to Optimize the Plastic Annealing Process in Your Plant

To get the most out of plastic annealing, it’s important to optimize the process to match the specific needs of your materials and production goals. Small adjustments in temperature, time, and cooling rate can have a significant impact on your product quality and operational efficiency.

Here’s how to improve the annealing process in your plant:

Select the Right Temperature for Your Material

When selecting a material for annealing, it’s important to understand that different plastics have distinct annealing temperature ranges. For example, annealing polycarbonate requires careful temperature control to prevent issues like deformation or property degradation.

Each polymer has a specific temperature range for stress relief. If the temperature is too low, you’ll waste energy without relieving enough stress, while too high a temperature can risk material damage.

Your optimal temperature for annealing will depend on the type of plastic, part geometry, stress levels, and material grade. Always run trials with sample parts, measuring dimensional changes before and after treatment to ensure the best results.

Important note: For filled or reinforced grades, use the lower end of the range to avoid matrix degradation around reinforcement fibers.

Calculate Hold Time Based on Part Thickness

Thicker sections require a more prolonged exposure to heat to penetrate fully and allow complete stress relaxation

Base calculations on the thickest section for complex geometries

Thinner areas will complete stress relief faster, but won't be harmed by extended exposure

Control Heating Rate to Prevent Thermal Shock

Rapid heating can cause surface stress or cracking, especially in brittle materials

Heat slowly and uniformly to bring the entire part to temperature together

Air circulation ovens work well for most applications

Use inert atmosphere or vacuum ovens for parts sensitive to oxidation at elevated temperatures

Manage Cooling Rate to Lock in Benefits

Cooling is as critical as heating

Fast cooling reintroduces thermal stress and negates the annealing effect

Allow parts to cool naturally inside the turned-off oven

Never quench annealed parts or expose them to drafts during cooldown

Parts should return to near room temperature before handling or subsequent processing

Support Parts Properly During Heat Treatment

Plastic becomes more compliant at annealing temperatures

Parts can sag or deform under their own weight if not properly supported

Use flat fixtures for sheet goods

Support long components at multiple points to prevent bending

Use fixtures that maintain critical dimensions for precision parts

Aluminum fixtures work well for most applications

Validate Results with Measurement

Check the dimensional stability before and after annealing on sample parts from each batch. Measure the critical dimensions immediately after annealing and again after 24-48 hours at room temperature.

Parts should show minimal dimensional change post-annealing compared to pre-annealing measurements. Significant change indicates either incomplete stress relief or incorrect process parameters.

Quality checks to implement:

Visual inspection for warping or surface defects

Dimensional verification of tolerance-critical features

Stress crack testing on witness samples

Comparison of first-piece to last-piece consistency

Set Up Process Controls for Repeatability

Document annealing parameters for each material and part family

Record temperature, hold time, heating rate, and cooling method

Use ovens with calibrated temperature controllers and maintain regular calibration records

Track oven loading density to prevent temperature non-uniformity

Overloading reduces air circulation and leads to inconsistent results

Integrate into Production Flow Efficiently

Schedule annealing after all machining operations, but before final inspection or assembly

Batch parts by material type and size to minimize oven changeover time

Pre-sort incoming work to keep similar parts together

Consider in-house capability versus outsourcing to heat treatment specialists

In-house control improves lead time and quality consistency

Outsourcing reduces capital investment and floor space requirements

Train Operators on Critical Parameters

Plastic annealing appears simple, but requires attention to detail

Operators need to understand why temperature accuracy matters and how improper handling affects results

Provide clear work instructions that specify temperature, time, loading patterns, and acceptance criteria

Include photos of proper part support methods

Build in verification steps where operators confirm oven temperature before loading and record actual cycle parameters for traceability

Common Challenges in the Plastic Annealing Process and How to Overcome Them

Even well-established plastic annealing processes can run into issues that affect part quality or production efficiency. Most problems trace back to temperature control, handling errors, or incomplete process documentation.

Recognizing these challenges early helps you implement corrective measures before they impact your scrap rate or lead time.

Challenge | Root Cause | Solution |

|---|---|---|

Warped parts after annealing | Inadequate support during heat treatment or uneven heating | Use proper fixturing that supports all sections. Verify oven temperature uniformity across the workspace. Check for blocked air circulation. |

Surface discoloration or degradation | Temperature too high or exposure to oxygen at elevated temperatures | Verify actual oven temperature against setpoint. Use an inert atmosphere for oxidation-sensitive materials. Reduce temperature or hold time. |

Inconsistent results between batches | Temperature variation, different loading densities, or operator variation | Calibrate oven temperature controllers regularly. Document and enforce standard loading patterns. Implement batch tracking with actual process parameters. |

Parts still fail stress testing post-annealing | Insufficient hold time, incorrect temperature, or cooling too fast | Increase hold time based on the thickest section. Verify temperature is within the material-specific range. Implement controlled cooling rate. |

Dimensional change during annealing | Temperature too high for material or insufficient part support | Lower annealing temperature. Improve fixturing to maintain critical dimensions. Consider using the material's lower annealing range. |

Long cycle times affecting throughput | Overly conservative parameters or small batch sizes | Optimize heating and cooling rates for your specific material. Increase batch size without overloading. Consider dedicated plastic annealing equipment for high-volume parts. |

Parts stick to fixtures or each other | Fixtures too hot, incompatible materials, or parts in direct contact | Use lower thermal mass fixtures. Place separator sheets between stacked parts. Ensure fixtures don't exceed material softening temperature. |

Cracking during heat treatment | Heating rate too fast or existing defects in material | Reduce heating rate for brittle materials. Inspect incoming material for pre-existing stress cracks. Check for contamination or moisture absorption. |

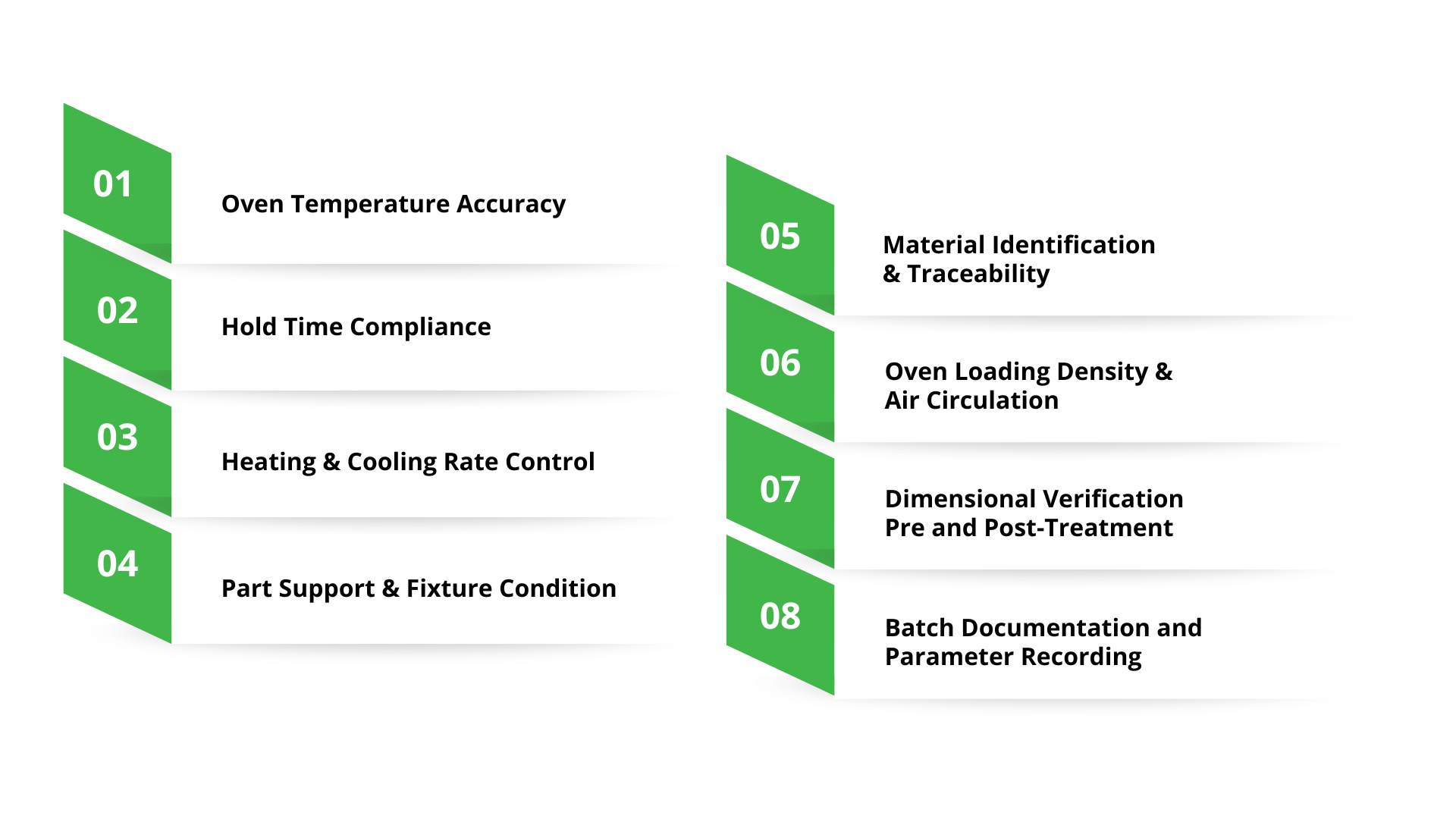

Key Factors to Monitor for Successful Plastic Annealing in Your Plant

Consistent annealing results depend on controlling the variables that affect heat transfer and stress relaxation. Your monitoring system should track both process parameters and quality outcomes to catch deviations before they become defects.

Oven Temperature Accuracy

What to do: Verify actual temperature matches setpoint using calibrated instruments at multiple locations within the oven workspace to ensure uniformity across the heating zone.

Why do it: Temperature variation beyond a narrow range creates inconsistent stress relief and can lead to part-to-part quality differences within the same batch.

Hold Time Compliance

What to do: Track actual time at temperature for each batch to ensure thicker sections receive adequate heat penetration for complete stress relaxation throughout the cross-section.

Why do it: Insufficient hold time leaves residual stresses that cause delayed failures, while excessive time wastes energy without additional benefit to part performance.

Heating and Cooling Rate Control

What to do: Monitor ramp-up speed to prevent thermal shock in brittle materials, and verify controlled cooldown to avoid reintroducing stresses that negate annealing benefits.

Why do it: Rapid temperature changes can cause surface cracking or internal stress formation that compromises the structural integrity you're trying to achieve.

Part Support and Fixture Condition

What to do: Check that fixtures maintain proper support without creating contact stress points, and verify that fixtures remain clean and free from contamination that transfers to parts.

Why do it: Sagging or deformation during treatment indicates inadequate support, while marks or stains suggest fixture material incompatibility with your process temperature.

Material Identification and Traceability

What to do: Confirm material type before processing, since different polymers require different temperature ranges, and annealing at the wrong parameters can destroy parts or provide no benefit.

Why do it: Mix-ups between similar-looking materials can lead to scrapped batches, making positive identification and segregation critical for quality control and cost management.

Oven Loading Density and Air Circulation

What to do: Maintain consistent spacing between parts to allow uniform heat distribution and avoid overloading, which blocks airflow and creates temperature gradients within the batch.

Why do it: Poor circulation causes some parts to under-anneal while others may overheat, resulting in quality variation that shows up during inspection or field use.

Dimensional Verification Pre and Post-Treatment

What to do: Measure critical features before annealing and after cooldown to detect unexpected dimensional changes that indicate process problems or incorrect temperature selection.

Why do it: Tracking dimensional stability provides early warning of parameter drift and helps validate that your process delivers the expected stress relief without unwanted side effects.

Batch Documentation and Parameter Recording

What to do: Record actual process conditions for every batch, including temperature profiles, hold times, and any deviations, to enable traceability when quality issues arise downstream.

Why do it: Complete documentation supports root cause analysis when defects occur and provides the data foundation for continuous process improvement and capability studies.

Economic Impact and Cost Considerations

Annealing adds a process step, which means added cost. But the calculation isn't as simple as energy bills and equipment depreciation. You need to look at what annealing prevents and where it creates value downstream.

Direct Cost Components

Energy consumption forms the largest ongoing expense

Equipment investment varies based on volume and requirements

Basic convection ovens for small batches require a lower capital outlay

Automated systems with atmosphere control cost more but deliver tighter process control

Maintenance includes temperature controller calibration and heating element replacement

Where Annealing Creates Savings

Scrap reduction from parts that no longer crack during machining or fail in assembly

Lower warranty claims when parts don't warp or crack in the field

Each return costs a replacement part plus shipping, handling, and customer relationship damage

Reduced machining time because cutting tools last longer without fighting internal stresses

Tighter tolerances using standard molding instead of expensive precision techniques

Throughput and Lead Time Factors

In-house capability eliminates the delays of sending parts out for heat treatment

Parts move directly from machining to inspection without vendor wait times

Lead time reduction is often worth more than direct cost savings for urgent orders

Batch processing efficiency improves as you optimize loading patterns and cycle times

Making the Business Case

Track these metrics to build your ROI calculation:

Current scrap rate on parts that would benefit from annealing

Material and labor cost per rejected piece

Annual warranty returns for stress-related failures

Full cost of processing each return, including handling

Compare against:

Equipment depreciation

Annual energy consumption

Labor hours for operation

Maintenance costs

Most operations find annealing pays for itself within the first year when applied to parts where residual stress drives quality problems.

Environmental Impact and Sustainability Considerations

Annealing consumes energy, which means it has an environmental footprint. But the calculation gets more complex when you factor in waste reduction and product longevity.

Operational Strategies That Reduce Impact

Batch processing minimizes energy waste by running the oven continuously

Temperature setpoint optimization identifies the minimum effective temperature for your parts

Heat recovery systems capture exhaust heat to preheat incoming parts or warm adjacent areas

Programmable controls minimize idle time and optimize heating profiles

Schedule cycles during peak solar production hours to maximize renewable utilization

Equipment Selection for Lower Impact

Modern ovens automatically reduce temperature during off-shifts

Gas-fired ovens can offer lower carbon intensity, depending on local grid mix

Solar or renewable energy integration works well because the process doesn't require an instant power response

Combined heating systems that handle multiple thermal processes cut equipment count

Integration with Other Manufacturing Processes

Annealing doesn't exist in isolation. Where you place it in your production sequence affects both part quality and operational efficiency.

Synergy with Injection Molding: In injection molding, parts often experience residual stresses during cooling. Annealing these parts helps to stabilize them before any further operations, reducing the chances of warping or cracking during subsequent steps like machining or bonding.

Optimizing with Extrusion: For extruded parts, annealing is crucial to relieve stress caused by the extrusion process. Annealing at the right stage ensures the material is easy to handle and shape during secondary operations, such as cutting or forming.

Additive Manufacturing (3D Printing): With 3D printing, parts are built layer by layer, and each layer can introduce its own stresses. Annealing is beneficial, but optional—and must be tuned for material-specific shrinkage.

How MD Plastics Can Help

The best way to minimize annealing requirements is to prevent residual stress from forming in the first place. At MD Plastics, we specialize in advanced plasticating systems that improve your injection molding process from start to finish.

Our solutions are designed to deliver better melt preparation, delivery, monitoring, and purging, increasing efficiency, precision, and ultimately, profitability.

Whether you're upgrading existing equipment or designing a custom system, we have the expertise to enhance your production line.

Here’s how we can help:

Inject-EX™ Plasticating Systems: A patented system that ensures more uniform and homogeneous melt, improving quality and control. Can be retrofitted onto existing presses.

Posi-Melt™ Multipurpose Screws: The most versatile screw technology, improving melt quality with up to 60% more exposure to the barrel wall for uniform homogenization.

MDP™ Non-Return Valves: Designed to enhance the accuracy of melt delivery, improving overall efficiency and part consistency.

Barrel Blitz Universal & Poly Clear Prime Purging Systems: Efficient purging solutions that reduce downtime, improve material changeover times, and ensure cleaner, more consistent production.

Melt-IQ™ System: Advanced monitoring system that tracks melt quality in real-time, providing crucial data for process optimization.

Contact us today to learn how our systems can enhance the performance and profitability of your molding operation.

FAQs

1. What is the main purpose of plastic annealing?

Annealing reduces internal stresses in plastic materials, improving their dimensional stability, strength, and durability, which prevents failures in later manufacturing steps.

2. How does annealing affect plastic part quality?

Annealing improves material consistency, leading to fewer defects, higher yield rates, and better performance in final applications, reducing scrap and failures.

3. What are the key parameters in the annealing process?

Critical factors include the annealing temperature, soak time, cooling rate, and the material’s thickness, all of which must be precisely controlled for optimal results.

4. Can plastic annealing be done in-house?

Yes, if you have the right equipment, in-house annealing can save time and improve control over your production process. Outsourcing is another option for reducing investment.

5. What materials benefit most from annealing?

Common materials like Acetal (POM), Polycarbonate (PC), Nylon (PA), and Acrylic (PMMA) benefit from annealing, improving their physical properties and reducing defects.