Temp-Sense™ Melt Sensors

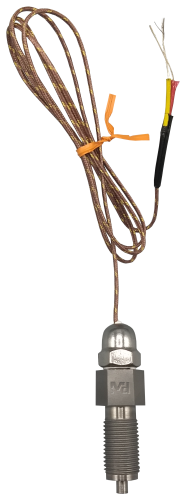

Micro Bead Sensors, Patent 6,649,095

- Measures Real Time Melt Temperature

- Industrial Grade

- High Temperature Flex Cable

- Extremely Accurate Polymer Readings

GET BETTER MELT MONITORING

Temp-Sense™ Melt Sensors measure polymer melt temperature real time when in direct contact with the melt pool. The designs are industrial grade products manufactured to withstand the harsh environments of an injection or extrusion process where high temperatures, pressures and corrosion are prevalent. A protective high temperature flexible armored or glass cable extends from its body for increased flexibility and life.

WHY YOU NEED THE

TEMP-SENSE ™ MELT SENOR

Temp-Sense™

Models TS-TJC36-2.0 and TS DYN-TJ36-3.9 measure polymer melt temperature real time when in direct contact with the melt pool. The designs are industrial grade products manufactured to withstand the harsh environments of an injection or extrusion process where high temperatures, pressures and corrosion are prevalent. A protective high temperature flexible armored or glass cable extends from its body for increased flexibility and life.

Temp-Sense™ Dynisco Style

Models TS-TJC36-2.0 and TS DYN-TJ36-3.9 measure polymer melt temperature real time when in direct contact with the melt pool. The designs are industrial grade products manufactured to withstand the harsh environments of an injection or extrusion process where high temperatures, pressures and corrosion are prevalent. A protective high temperature flexible armored or glass cable extends from its body for increased flexibility and life.

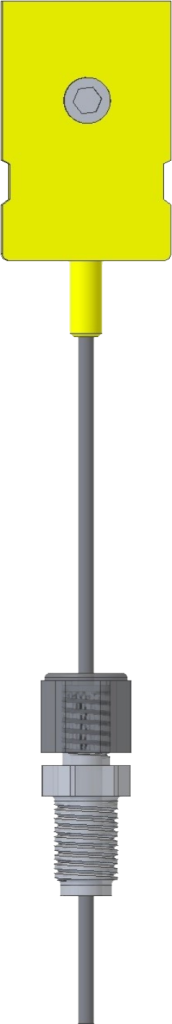

Temp-Sense™ In-Mold Sensor “CB-100”

Md Plastics developed the CB-100 Flush Mount in-mold Temperature Sensor as a tool to analyze the polymeric flow inside the cavity. The Temp-Sense Sensor is precise enough to sense the molten polymer flow front as it enters the cavity and proceeds to the sensor position. As the Hot flow front progresses in the cavity from the gate position, the flow front heats up the air that is being displaced to the vent position and closer to the sensors micro-bead. The time it takes to reach the sensor is indicative of the injection velocity but the increased temperature along it’s path can be used to trigger the Melt-IQ to determine Good/Bad part production. The temperature of the melt and mold make up two of the four “Plastics Variables” that determine how a part is formed.

Melt and cavity temperature can be critical to many parts, especially those made with semicrystalline materials and requiring tight dimensional tolerances. Thermodynamic stability in injection molding with crystalline material is extremely critical. Achieving proper temperatures after a cycle break can require numerous cycles.

The flush mount temperature sensor is small enough to be installed in smaller molds and molds with more challenging geometries. The sensor is very easily installed in position and held in position with an epoxy solution. In order to find the best location for the sensor, a short shot progression test should be made and the sensor placed in the last to fill cavity, towards the last to fill position before the vent. Placement of the Temp-Sense™ Sensor (USpatents #7,585,166 & 6,649,095) into the last to fill cavity will enable the processor to verify the thermal properties of the Polymer, promising 100% product verification. It’s as simple as 1,2,3!

The Temp-Sense™ Melt sensor takes the applied pressure (P) by the melt and measures the work applied to the polymer. The actual thermocouple meter readout displayed in our Melt-IQ unit shows the thermal energy being imparted to the polymer instantaneously for a unique “LOOK” into the thermodynamics of the injection unit.

Temp-Sense™ In-Mold Sensor “CF25-28”

Md Plastics developed the CF25-28 Flush Mount in-mold Temperature Sensor as a tool to analyze the polymeric flow inside the cavity. The Temp-Sense Sensor is precise enough to sense the molten polymer flow front as it enters the cavity and proceeds to the sensor position. As the Hot flow front progresses in the cavity from the gate position, the flow front heats up the air that is being displaced to the vent position and closer to the sensors micro-bead. The time it takes to reach the sensor is indicative of the injection velocity but the increased temperature along it’s path can be used to trigger the Melt-IQ to determine Good/Bad part production. The temperature of the melt and mold make up two of the four “Plastics Variables” that determine how a part is formed.

Melt and cavity temperature can be critical to many parts, especially those made with semicrystalline materials and requiring tight dimensional tolerances. Thermodynamic stability in injection molding with crystalline material is extremely critical. Achieving proper temperatures after a cycle break can require numerous cycles.

The flush mount temperature sensor is small enough to be installed in smaller molds and molds with more challenging geometries. The sensor is very easily installed in position and held in position with an epoxy solution.

In order to find the best location for the sensor, a short shot progression test should be made and the sensor placed in the last to fill cavity, towards the last to fill position before the vent. Placement of the Temp-Sense™ Sensor (US patents #7,585,166 & 6,649,095) into the last to fill cavity will enable the processor to verify the thermal properties of the Polymer, promising 100% product verification. It’s as simple as 1,2,3!

Get the Industry's BEST Melt Monitoring Sensors

IT'S EASIER THAN EVER TO

GET BETTER MELT MONITORING

1. Request A Quote & Talk To Our Owner

Md Plastics' Owner Mike Durina will talk you through the process of how the Temp-Sense™ Melt Sensor will help your molding performance.

2. Install the Melt-IQ™ System

Install the Temp-Sense™ Melt Sensor onto a new or modified nozzle body. We can design or modify any nozzle body for your IMM machine.

3. Save Time, Save Money, Save Materials

Maximize Yield and Profits with Better Melt Monitoring and turn your Injection Molding Machine into a 5-Star quality control manager.

TEMP-SENSE ™ MELT SENSORS

ARE USED ACROSS THE WORLD

DON'T JUST TAKE OUR WORD

WATCH TO SEE HOW IT WORKS

GET BETTER MELT MONITORING TODAY CONTACT Md PLASTICS