Polymer melt viscosity measures how much your material resists flow during processing. It influences injection pressure, fill patterns, cycle speed, and part quality. You're working with a fluid that doesn't behave like conventional liquids.

Apply more force, and the viscosity drops. Raise the temperature, and it flows more easily. Change the molecular weight, and everything shifts again. These behaviors affect your daily decisions on the floor, from selecting processing windows to diagnosing defects.

Viscosity isn't just a lab measurement. It's the reason one resin processes cleanly at 230°C while another needs 260°C, or why increasing injection speed suddenly improves fill without raising pressure.

This guide explains polymer melt viscosity, how to measure it, and how to apply that knowledge on the manufacturing floor.

Key Takeaways:

Polymer melts are shear-thinning fluids: Increasing injection speed or screw RPM actually reduces effective viscosity, allowing faster cycles without adding heat or pressure.

Temperature swings destroy consistency: Even minor variations can change viscosity significantly, creating fill imbalances, surface defects, and unpredictable part quality across production runs.

High viscosity accelerates equipment wear exponentially: High viscosity increases equipment wear, causing parts like screws and barrels to need replacement more often than usual.

Melt Flow Index provides a quick viscosity reference: A high MFI means low viscosity and easy flow. Low MFI indicates high viscosity, requiring more robust injection systems and higher pressures.

Viscosity optimization delivers substantial energy savings: Proper material selection, temperature profiling, and screw design reduce motor load, heating demands, and overall power consumption throughout production.

What is Polymer Melt Viscosity?

Polymer melt viscosity is the measure of a molten polymer's resistance to flow. When you heat a polymer above its melting point, it transitions into a viscous liquid. Viscosity quantifies how thick or thin a liquid is, or more precisely, how much force you need to make it move.

In practical terms, viscosity determines:

During Processing

How much injection pressure your machine needs

How fast the melt fills the mold cavity

Whether the material flows uniformly through gates and runners

How much energy you consume during extrusion or molding

For Final Product Quality

Surface finish and gloss levels

Weld line strength where flow fronts meet

Dimensional accuracy and part consistency

Internal stress distribution

Higher viscosity means the polymer resists flow and requires more pressure or heat. Lower viscosity means it flows more easily, but can be harder to control.

You're constantly managing viscosity when you adjust barrel temperatures, modify screw speeds, or select processing parameters for a new material grade.

Factors Affecting Polymer Melt Viscosity

Polymer melt viscosity isn't fixed. It shifts based on material properties, processing conditions, and what you add to the base resin. Understanding these factors helps you predict how a material will behave in your equipment and what adjustments you'll need to make.

Polymer Type & Molecular Structure

Different polymers have different viscosity profiles. Polypropylene flows more easily than polycarbonate. High-density polyethylene behaves differently from low-density grades. Molecular weight plays a major role here. Longer polymer chains tangle more, creating higher resistance to flow.

Temperature

Temperature is your primary tool for controlling viscosity. As you increase the heat, polymer chains move more freely and viscosity drops. This relationship is exponential, not linear. A 10°C increase can cut viscosity significantly.

Processing Implications

Higher barrel temperatures reduce the load on your injection system

You consume more energy to maintain elevated melt temperatures

Temperature controllers need a tight tolerance to keep viscosity consistent

Overheating degrades some polymers, so there's always a processing window

Cooling time in the mold increases with higher melt temperatures

Our Melt-IQ™ System and Temp-Sense™ Melt Sensors offer real-time melt temperature monitoring, allowing for precise control of the molding cycle. These advanced systems optimize melt quality, reduce energy consumption, and improve consistency.

In addition, MD Plastics offers high-performance barrels, designed for optimal corrosion and abrasion resistance in challenging environments.

Our bimetallic cylinders and precision-honed barrels ensure maximum durability and optimal performance.

Explore our full range of high-performance solutions today.

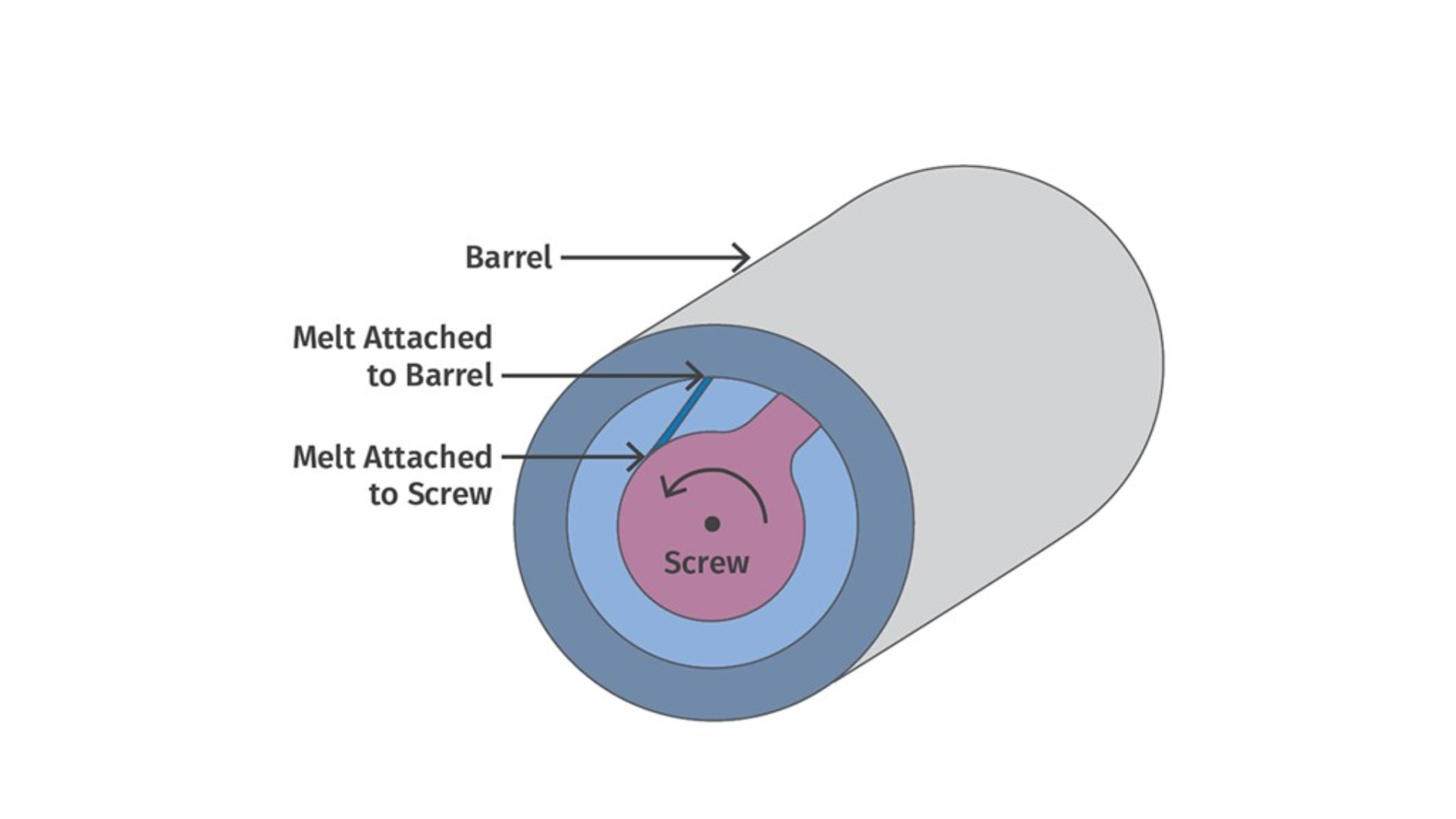

Shear Rate

Shear rate describes how fast layers of molten polymer slide past each other during flow. When you increase injection speed or extrusion rate, you're increasing shear rate. Most polymer melts are shear-thinning, meaning their viscosity drops as shear rate rises.

Impact on Equipment and Processing

Faster injection speeds can actually reduce the pressure required

Shear heating occurs at high rates, adding heat to the melt beyond barrel settings

Gate size and runner design affect local shear rates and flow behavior

Screw RPM directly controls shear rate during plasticization

High shear rates can degrade heat-sensitive polymers

Additives & Fillers

Adding glass fiber, minerals, colorants, or stabilizers changes the base polymer's viscosity. Fillers generally increase viscosity because they disrupt flow and add solid particles to the melt. Some additives act as processing aids and reduce viscosity.

Polymer Melt Flow Index (MFI)

MFI measures how many grams of polymer flow through a standard orifice in 10 minutes under specific temperature and load conditions. It's an inverse indicator of viscosity. High MFI means low viscosity and easy flow. Low MFI means high viscosity and stiffer material.

The Impact of Viscosity on Manufacturing Efficiency

Viscosity directly affects your bottom line. It determines how fast you can run, how much energy you consume, and how long your equipment lasts. Small changes in viscosity create measurable differences in production costs and output quality.

Cycle Time

High-viscosity materials flow slowly through runners, gates, and into mold cavities. The polymer needs more time to fill completely, especially in thin-wall sections or complex geometries. You're forced to extend the injection time, which pushes out your overall cycle.

Business Impact

Longer cycles mean fewer parts per hour from each machine

Production capacity drops without adding equipment or shifts

Energy costs rise because heaters and hydraulics run longer per part

Labor efficiency decreases when operators manage fewer parts per day

High-viscosity grades may require mold design changes to maintain acceptable cycle times

Energy Consumption

Moving a high-viscosity polymer requires more force. Your injection motor works harder. Barrel heaters consume more power to reach temperatures that bring viscosity down. Hydraulic systems strain under increased pressure demands.

Business Impact

Higher injection pressures translate directly to kilowatt-hour increases

Maintaining elevated barrel temperatures for viscous materials adds a continuous energy load

Pump motors running at capacity wear faster and fail sooner

Energy costs per part rise, eating into margins on high-volume runs

Optimizing viscosity through material selection or processing conditions can cut energy consumption by 10-20%

Plants with multiple machines see energy savings multiply across the floor

Component Wear and Tear

Viscous polymer creates friction and mechanical stress throughout your processing equipment. Screws push harder during plasticization. Barrels experience more abrasion. Check valves seal against higher backpressure. Every component that contacts the melt works under greater load.

Business Impact

Screws and barrels wear faster, requiring replacement every 12-18 months instead of 3-5 years

Check valves fail more frequently, causing shot-size inconsistency and unplanned downtime

Nozzles and hot runner systems develop leaks or blockages sooner

Preventive maintenance intervals shorten, increasing labor and spare parts costs

Unexpected component failure stops production and delays orders

Switching to filled or reinforced high-viscosity grades accelerates wear exponentially

Final Product Quality

Viscosity variation batch-to-batch creates inconsistent fill patterns, surface finish, and mechanical properties. When viscosity is too high, short shots and incomplete fills occur. When it's too low, flash and dimensional issues appear.

Business Impact

Inconsistent viscosity leads to higher scrap rates and rejected parts

Rework cycles add labor costs and delay shipments

Customers return parts that don't meet dimensional or appearance specs

Quality inspections take longer when viscosity isn't controlled

Process windows narrow with viscosity-sensitive materials, making setup harder

Weld lines in high-viscosity materials are weaker, increasing field failures

Tight viscosity control reduces defect rates and improves first-pass yield

How to Control and Optimize Polymer Melt Viscosity

You can't eliminate viscosity variation entirely, but you can manage it. The right combination of material selection, processing parameters, and equipment settings keeps viscosity within your target range and maintains consistent output.

Control Method | How It Works | When to Use | Limitations |

|---|---|---|---|

Increase Melt Temperature | Reduces viscosity by increasing molecular mobility | High injection pressures, slow fill times, incomplete fills | Excessive heat degrades some polymers, increases cooling time, and raises energy costs |

Adjust Shear Rate | Higher injection speed or screw RPM lowers effective viscosity through shear-thinning | Need faster cycles, want to reduce pressure without adding heat | Can cause shear degradation, increase wear, mand ay create surface defects |

Select Lower MFI Material | Switch to a grade with higher flow characteristics | Switching applications, thin-wall parts, complex geometries | May sacrifice mechanical properties, and availability can be limited |

Add Flow Modifiers | Chemical additives reduce intermolecular friction | Locked into specific resin, need incremental improvement | Adds material cost, can affect final properties, requires testing |

Optimize Screw Design | Better mixing and shear control through screw geometry | Processing multiple materials, frequent viscosity issues | Requires capital investment, downtime for changeover |

Control Residence Time | Prevents degradation that raises viscosity | Heat-sensitive materials, long cycle times | Limited by part size and process requirements |

Important: Monitor your process with consistent viscosity measurement. Track injection pressure, fill time, and part weight shot-to-shot. These indicators tell you when viscosity is drifting before quality problems appear.

Key Components for Managing the Viscosity of Polymer Melt

Your equipment directly determines how well you can control viscosity and handle different polymer grades. The right components give you processing flexibility. The wrong ones create bottlenecks and quality issues.

Injection Units & Screws

Screw design is critical for viscosity management. The screw does more than push material forward. It generates shear, adds heat through friction, and homogenizes the melt. Length-to-diameter ratio (L/D) affects how much work the screw can do on the polymer.

Design Considerations

General-purpose screws work for medium-viscosity materials but struggle with extremes

High-viscosity polymers need deeper feed sections and gradual compression ratios

Barrier screws improve mixing and temperature uniformity, reducing viscosity variation

Longer screws provide better melting for high-viscosity grades

The compression ratio must match the polymer family - too aggressive creates excessive shear and degradation

Mixing sections help break up viscosity gradients before injection

Best Practices for High-Viscosity Materials

Choose screws with larger flight depths in the feed zone to handle denser pellets

Reduce the compression ratio or lower to prevent overheating

Add mixing elements only if the material requires homogenization. Extra shear can degrade sensitive polymers

Verify screw recovery time matches your cycle. Inadequate recovery causes short shots

Use hard-face or nitride screws when processing filled materials to extend wear life

Match screw design to your typical viscosity range rather than trying to handle everything with one screw

Modern screw technologies like MD Plastics' Posi-Melt™ technology address many traditional viscosity challenges through improved geometry.

Our patented design increases barrel wall contact by up to 60%, which creates more uniform melt temperatures and reduces viscosity variation shot-to-shot.

These screws handle materials from LCP to rigid PVC, making them versatile options when you're processing multiple polymer families with different viscosity profiles.

Request a free quote today and improve your polymer melt preparation with MD Plastics.

Heaters & Temperature Controllers

Temperature accuracy directly translates to viscosity consistency. Band heaters maintain barrel zones at setpoints, but their performance varies widely by design and quality. Controllers read thermocouples and adjust power output to maintain target temperatures.

Why Precision Is So Important

A 5°C temperature swing can change viscosity by 15-20% in some polymers

Poor zone-to-zone temperature control creates viscosity gradients in the melt

Overshooting temperature degrades heat-sensitive materials and changes their flow properties

Undershooting temperature increases viscosity and can cause incomplete plasticization

Selecting the Right Components

Ceramic band heaters respond faster and distribute heat more evenly than mica heaters

PID controllers with auto-tuning maintain a tighter temperature tolerance than simple on-off controllers

Multi-zone control (5-7 zones minimum) lets you create optimal temperature profiles for viscosity management

Invest in controllers with data logging to track temperature stability over time

Insulation jackets on barrels reduce energy loss and improve temperature consistency

Thermocouples should be positioned correctly—poor contact gives false readings and inconsistent control

Pumps & Valves

In extrusion systems and hot runner applications, pumps move polymer melt at controlled rates. Gear pumps are common for metering high-viscosity materials. Valves control flow direction and timing. Both components must handle the specific viscosity range of your material.

Sizing for Viscosity

Gear pumps for high-viscosity polymers need larger motors and reinforced gearing

Undersized pumps cavitate or stall when viscosity exceeds their design range

Valve seats and seals must withstand pressure spikes from viscous materials

Hot runner valve gates require adequate actuation force to open and close against melt pressure

Preventing Wear and Failure

High-viscosity melts accelerate wear on pump gears and valve stems

Select pumps with hardened steel gears when processing filled or abrasive materials

Regular maintenance intervals should shorten for high-viscosity applications

Backup pumps and valves reduce downtime when wear-related failures occur

Monitor discharge pressure as an indicator of component wear—rising pressure often signals internal degradation

Molds & Cooling Systems

Mold design affects how viscosity behaves during cavity fill and packing. Gate size, runner dimensions, and venting all interact with viscosity. Cooling systems then solidify the part, and cooling efficiency depends partly on melt viscosity.

Mold Design Impacts

Small gates increase local shear rate, which lowers effective viscosity but can cause jetting

Thick runners reduce pressure loss when processing high-viscosity materials

Inadequate venting traps air that prevents complete fill in viscous melts

Hot runner systems maintain melt temperature and viscosity throughout the flow path

Cold runners allow temperature drop and viscosity increase between shots

Cooling System Considerations

High-viscosity melts take longer to cool because they enter the mold hotter

Conformal cooling channels improve heat extraction uniformity and reduce cycle time

Cooling line flow rate must match the thermal load from the melt

Temperature controllers for mold water maintain consistent cooling across production runs

Inconsistent mold temperatures create viscosity-related fill imbalances in multi-cavity molds

Fast-cycling thin-wall applications need aggressive cooling even with lower-viscosity materials

Conclusion

Viscosity challenges don't have to dictate your production limits or drive up your operating costs.

The right combination of material knowledge, process control, and equipment design keeps viscosity within manageable ranges across different polymer grades and production demands.

When you address viscosity systematically rather than fighting it part by part, you see improvements in cycle time, energy consumption, component longevity, and product consistency that directly impact profitability.

MD Plastics has spent over two decades engineering solutions for viscosity challenges that slow down production lines and drive up costs.

Our plasticating components are designed with the real-world behavior of polymer melts in mind, not outdated assumptions from decades ago.

We work with injection molders to identify the specific viscosity issues affecting their operations and provide components that deliver measurable improvements.

Get in touch with our technical team to discuss your viscosity challenges and find out which solutions fit your process.

FAQs

What is the viscosity of polymer melt?

Polymer melt viscosity measures how much molten polymer resists flow during processing. It determines injection pressure requirements, fill speed, and energy consumption throughout the manufacturing cycle.

How does temperature affect polymer melt viscosity?

Higher temperatures reduce viscosity by increasing molecular mobility. The relationship is exponential, so modest temperature increases can significantly lower viscosity and reduce the pressure needed for injection.

What is shear-thinning behavior in polymer melts?

Most polymer melts become less viscous when forced to flow faster. Increasing injection speed or screw RPM raises shear rate, which lowers effective viscosity without adding heat.

How does MFI relate to polymer melt viscosity?

Melt Flow Index is an inverse indicator of viscosity. High MFI values mean low viscosity and easy flow. Low MFI values indicate high viscosity and stiffer materials that require more processing force.

Why does high viscosity increase manufacturing costs?

High-viscosity materials extend cycle times, consume more energy for heating and injection, accelerate equipment wear, and create quality issues that increase scrap rates and maintenance expenses.