In the world of manufacturing, injection molding has long stood as a cornerstone process for producing plastic parts with precision, efficiency, and consistency. From medical devices and automotive components to consumer goods and packaging, injection molding continues to shape the products we rely on every day. However, as technology evolves and global demands intensify, the industry faces increasing pressure to innovate. Enter a novel Inject-EX TM Design.

At Md Plastics, we have been helping injection molders be more profitable since 1999 by designing and manufacturing superior plasticating components and developing entirely new technologies.

The State of Injection Molding Today

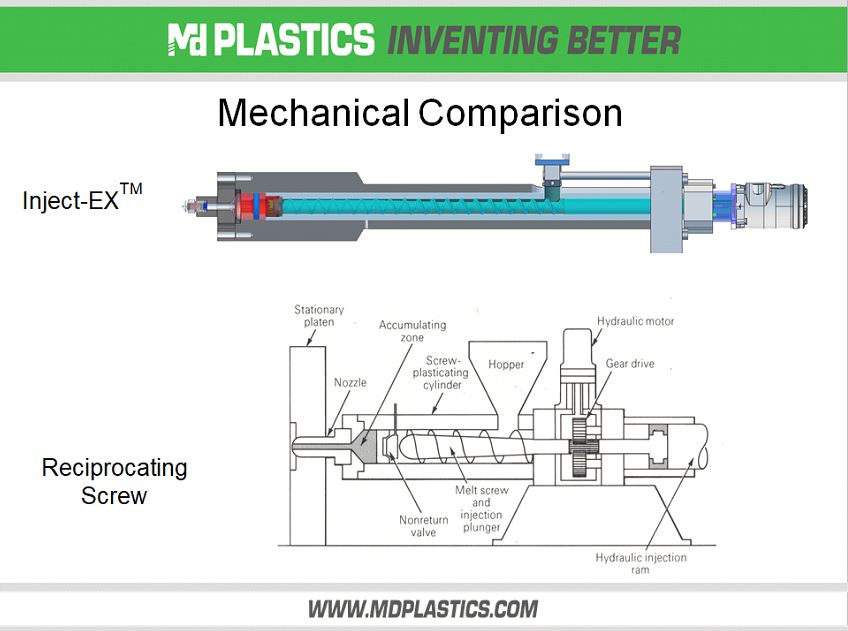

The manufacturing process of injection molding is a primary form of manufacturing of plastic products in the world today. The demands of high molded part tolerances, dimensional stability, and shot-to-shot repeatability are increasing and better controls and mechanical components of injection machines are required to meet the increasing demands. The primary design for injection molding machines today utilize what is referred to as “the reciprocating screw” process which is a 70 year old process of feeding, melting, homogenizing, pumping and injecting polymeric material. There are four widely recognized deficiencies of the reciprocating screw injection molding process that lead to molded part variation:

- Viscosity variations that are primarily caused by poor melt quality and homogenization, (every pellet is exposed to a different shear rate and residence time)

- Variation in the amount of polymer downstream of the Non Return Valve due to constant pressure flow changes

- Variation in the Quantity of Melt displaced due to inconsistent Non Return Valve closure

- No accurate way to measure the mass density displacement that takes place, theretofore, the Molding Machine does not know if it produced a Good or Bad Part!

Accordingly, this invention relates to an improved injection molding system of melt preparation, division between the melting chamber and melt pool, accurate dispensing of the melt and the ability to measure the volumetric mass density that is injected into a mold.

What Is the Inject-EX TM and how does it address the deficiencies of the existing technology?

The present invention utilizes a stationary (relative to the feed opening), non- reciprocating helical plasticating screw that is housed in a inner barrel that is connected to a plunger head, drive housing, and motor comprising an integrated unit that moves axially in unison within an outer barrel/pressure vessel during the injection process along one axis. The means for moving the assembly from the upstream end to the downstream end and into a mold is provided by conventional pneumatic, hydraulic or electric cylinders, ball-roller screws or other suitable method. By not allowing the helical screw to reciprocate relative to the fed port opening during the plasticating process, each plastic pellet or powder sees the same residence time, heat and shear history, regardless of the shot size which improves melt quality and homogenization as the screw acts like an extruder screw which is well known to those skilled in the art to be the preferred way to melt plastic pellets, this feature addresses deficiency #1 listed above.

The plunger head that is connected to the distal end of the heating cylinder has a unique mechanically operated check valve-shutoff mechanism similar to the authors US patent 8,734,146 B2 (that is in the normally closed position) opened when the screw is rotated pumping prepared molten polymeric fluid through the mechanism, downstream into the awaiting pressure vessel where the shot size is accumulated. The instantaneous closure of the plunger head when the screw stops turning assures that the melting chamber and the melt pool of the pressure vessel are distinctly separated, and assures that no backflow of material is allowed to enter the helical plasticating screw, this feature addresses deficiencies #2 and 3.

The outside diameter of the plunger head is fit in close proximity to the inside diameter of an outer barrel/pressure vessel in communication therewith so as to act like a cylinder head whose purpose is to form a seal while in the plasticating mode as well as the injection forward mode. The entire assembly is fitted with a nozzle tip for transfer of the molten polymeric material into a mold.

A direct drive motor is connected to the helical screw and is nestled to the drive housing that is free to reciprocate as a unit along a linear rail/guide system providing a more effective, inexpensive, and efficient method for melting and injecting molten polymeric fluid into an injection mold.

The design allows for a mass density sensor or the like to be added to the melt pool for determining the state of the melt in the pressure vessel and checking for volumetric mass density by adding a control feature to the system’s program whereas the screw/plunger unit can be held in position while the screw continues to rotate to determine a more precise mass density with a compressible polymeric fluid. This feature cannot be utilized in a reciprocating screw design because the screw and pressure vessel are always connected by a single flow path which leads to constant pressure flow changes as described in deficiency #2 and 4 above.

Adapt Today for a Smarter Tomorrow

The injection molding industry stands on the edge of a new era — one defined by speed, intelligence, and resilience. Automation, robotics and New Mechanical designs are not optional upgrades; they are critical tools for competing in a global, fast-paced marketplace. Forward-thinking manufacturers who embrace these changes today will be tomorrow’s leaders.

At Md Plastics, we’re here to help you achieve your goals. Let us help you harness the power to optimize your melt management, and build a smarter, more profitable molding operation from the ground up.

Contact Us Today

Are you ready to take your injection molding operations to the next level? Whether you’re exploring automation for the first time or looking to refine an existing system, Md Plastics is your trusted partner for technical knowledge, proven solutions, and innovative design.

Reach out to us to learn more about our products, technologies, and consulting services.

Let’s build the future of injection molding — together.