Temp-Sense™

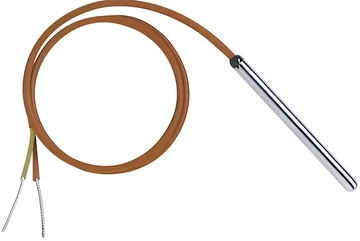

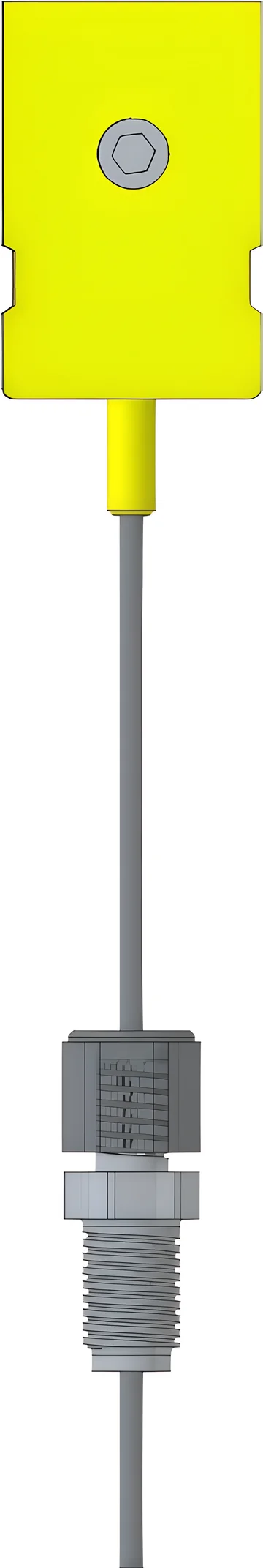

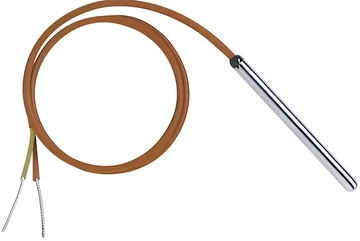

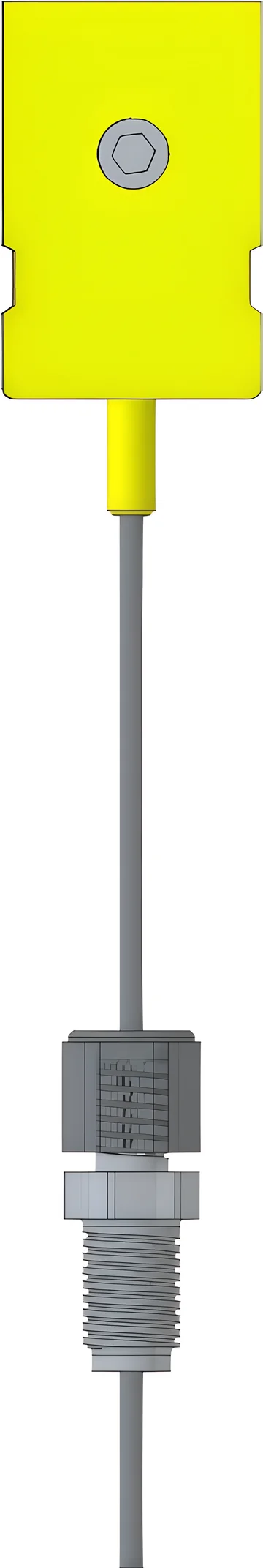

- Direct Contact Measurement

- Multiple Model Options

- High-Temp Environments

US Patent Technology

ISO 9001:2015

Advanced temperature profile control systems featuring patented micro-bead thermocouple technology for precise polymer melt monitoring. Our comprehensive range includes in-mold sensors, monitoring systems, and plasticating solutions engineered for injection molding, extrusion, and LSR applications with real-time accuracy and industrial durability.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 7 results

What temperature range can these sensors handle?

Our sensors operate continuously up to 450°C with industrial-grade durability for polymer processing applications.

How accurate are the temperature measurements?

Can sensors withstand high-pressure environments?

Are the systems compatible with existing equipment?

What installation support is provided?

How do monitoring systems improve quality control?

What makes the patented technology unique?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components requiring consistent quality and thermal control for safety-critical applications.

Sterile plastic components with strict quality requirements and precision molding for healthcare applications.

Plastic housing and component manufacturing requiring precise dimensional control and surface finish quality.

High-volume polymer processing and extrusion operations requiring continuous temperature monitoring and control.

Talk to our experts for custom solutions and tailored guidance.

Industry-leading accuracy with ±1°C precision and sub-second response times for unmatched real-time polymer melt monitoring and process control.

Proven expertise since 1999 with 8 granted patents and deep understanding of plasticating unit importance in injection molding processes.

Comprehensive solutions from sensors to monitoring systems with seamless compatibility and end-to-end technical support for optimal performance.

Connect with our technical team for customized solutions and receive expert guidance on sensor selection and system implementation.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com