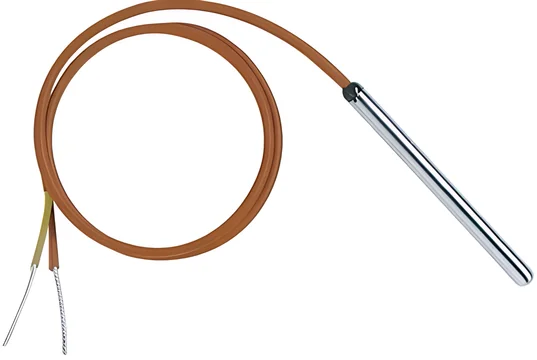

Inject-EX™ Plasticating System

- Stationary screw eliminates deficiencies

- Ultra precise shot control mechanism

- Real-time melt density verification

ISO 9001:2015

Advanced injection molding machine control systems featuring patented temperature monitoring, melt quality sensing, and process optimization technologies. Designed to enhance manufacturing precision, reduce scrap rates, and improve overall production efficiency for thermoplastic and LSR processing applications.

What materials are compatible with these control systems?

Our systems support thermoplastics, thermoset LSR materials, and recycled materials across various processing applications.

Can these systems retrofit existing injection molding machines?

How accurate is the temperature monitoring capability?

What industries benefit most from these control systems?

Do you provide technical support and installation services?

What makes your control systems different from competitors?

How do these systems help reduce manufacturing costs?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components with consistent quality control for automotive suppliers.

Sterile plastic component production with precision molding and quality validation systems.

Plastic housing components manufacturing with consistent dimensional accuracy and surface quality.

High-volume plastic processing operations requiring continuous monitoring and process optimization.

Talk to our experts for custom solutions and tailored guidance.

Over 8 patented technologies including revolutionary Inject-EX™ and Melt-IQ™ systems that deliver measurable improvements in quality and productivity.

Deep plasticating expertise since 1999 with proven track record serving leading manufacturers like Foxconn, TE Connectivity, and Boston Scientific.

Direct consultation with founder Mike Durina plus comprehensive installation, retrofit services, and ongoing technical support worldwide.

Connect with our plasticating specialists for custom system design, retrofit solutions, and technical guidance tailored to your manufacturing requirements.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com