Melt-Profiler™ II System

- Dual Sensor Reading Capability

- Built-In Audible Alarm System

- Stand-Alone Operation Design

US Patent Protected

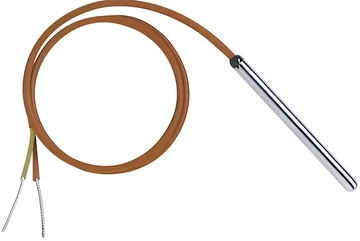

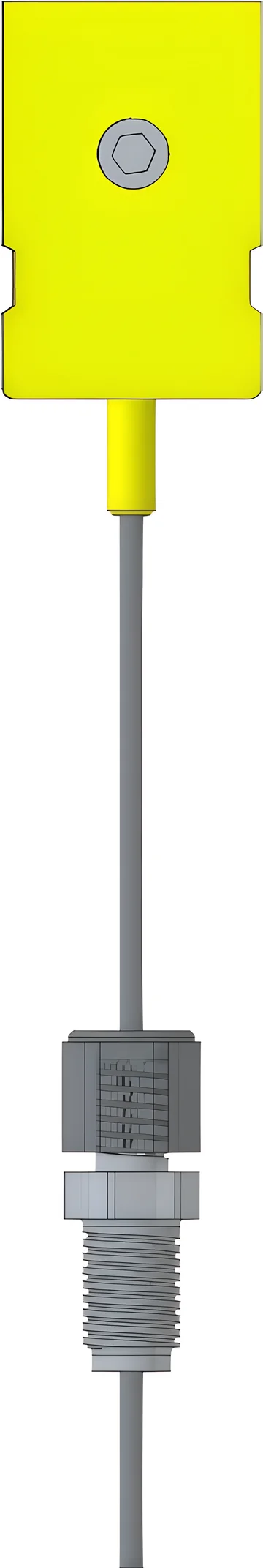

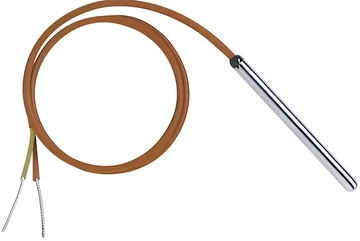

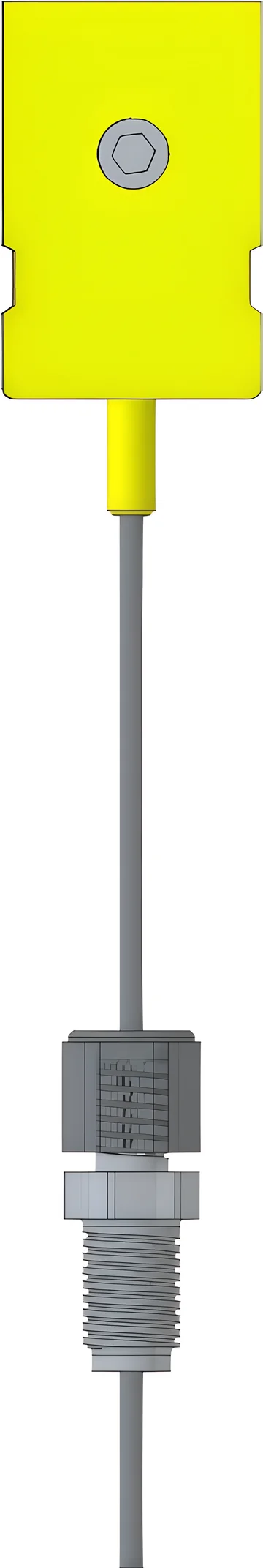

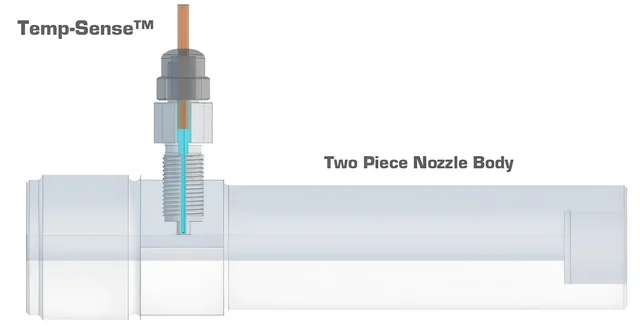

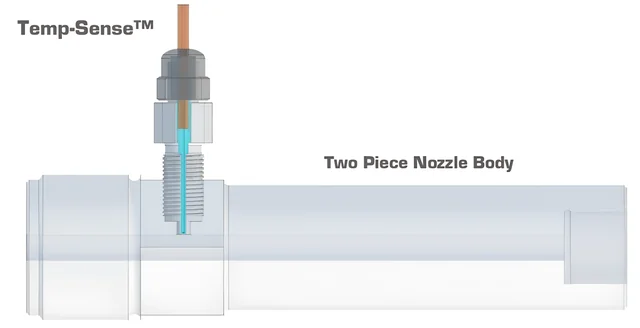

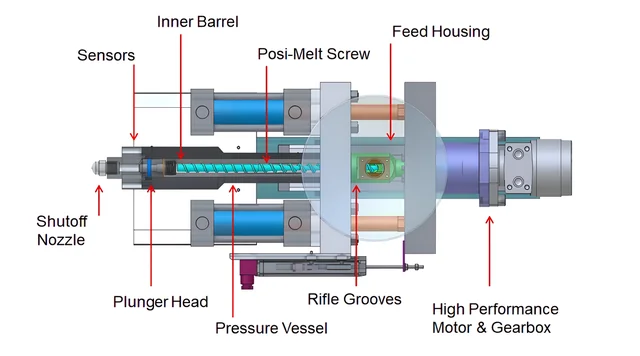

Advanced injection molding sensors for real-time process monitoring and quality control. Our patented temperature sensors and monitoring systems provide precise melt temperature measurement, flow front detection, and process optimization for injection molding operations across automotive, medical, and electronics manufacturing industries.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

How do you detect short shots in injection molding?

Use in-mold temperature sensors placed at the last-to-fill cavity location to monitor flow front progression and detect incomplete fills.

What is PLC in injection molding?

What temperature accuracy can these sensors achieve?

Can sensors withstand high injection molding pressures?

What is the maximum temperature range for these sensors?

Do you provide installation support for the sensors?

Are the sensors compatible with existing molding equipment?

Talk to our experts for custom solutions and tailored guidance.

Precision temperature monitoring for injection molded automotive components and plastic parts production

Critical temperature control for sterile plastic components and precision medical device molding

Quality monitoring for plastic housing components and electronic device enclosure manufacturing

High-temperature and pressure monitoring for industrial plastic processing and extrusion operations

Talk to our experts for custom solutions and tailored guidance.

Our proprietary micro-bead sensing technology with multiple US patents delivers unmatched accuracy and reliability for critical process monitoring applications.

Founded by plastics engineering expert Mike Durina, we bring decades of hands-on injection molding expertise to every sensor solution and application.

From installation guidance to technical consultation, we provide comprehensive support with direct access to our engineering team for optimal implementation.

Connect with our technical team for personalized sensor recommendations and application-specific solutions. Quick response guaranteed.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com