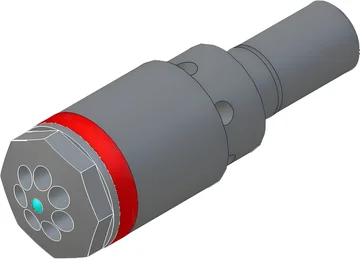

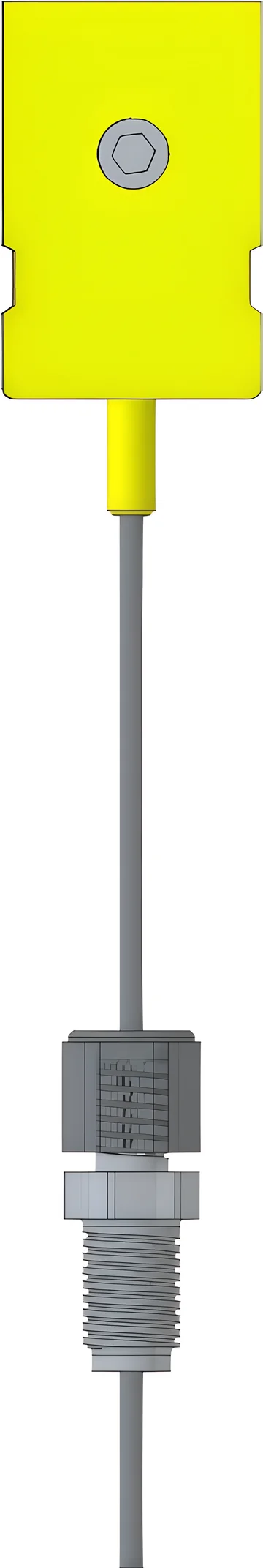

Mini-Shut™ Automatic Shut-Off Nozzle

- Instant automatic shutoff

- Universal machine compatibility

- Eliminates drooling & stringing

US Patent Protected

Advanced injection molding technologies featuring patented plasticating systems, precision temperature monitoring, and automatic shut-off solutions. These cutting-edge components enhance melt quality, reduce scrap rates, and optimize production efficiency for modern injection molding operations across automotive, medical device, and electronics manufacturing industries.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 10 results

What is the advanced injection molding process?

Advanced injection molding incorporates precision monitoring, automated controls, and optimized plasticating systems for enhanced quality and efficiency.

What is the future of injection molding?

What is the future of advanced molding?

Who makes the best injection molding machines?

How do temperature sensors improve injection molding quality?

What are the benefits of automatic shut-off nozzles?

How long do advanced injection molding components last?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components for vehicles requiring consistent quality and advanced process control

Sterile plastic components and precision molding for medical devices with strict quality requirements

Plastic housing components and electronic parts manufacturing with precise dimensional control

Heavy-duty plastic components and industrial parts requiring advanced plasticating technologies

Talk to our experts for custom solutions and tailored guidance.

Pioneering advanced injection molding technologies with 8 patents and revolutionary plasticating solutions that transform manufacturing processes.

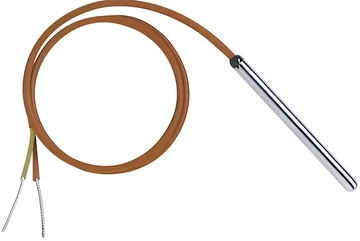

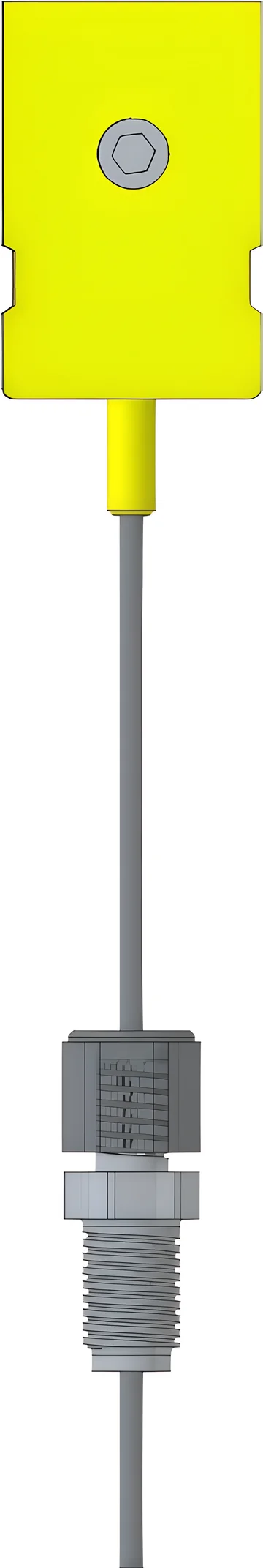

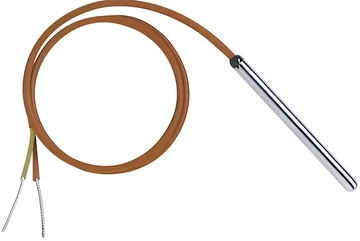

Exclusive patented systems including Inject-EX™, Mini-Shut™, and Temp-Sense™ technologies that deliver measurable improvements in quality and efficiency.

Direct consultation with founder Mike Durina and technical team providing custom solutions backed by decades of plastics industry expertise.

Connect with our technical experts for custom system design and implementation guidance. Quick response from experienced engineers.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com