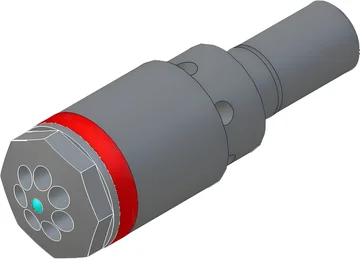

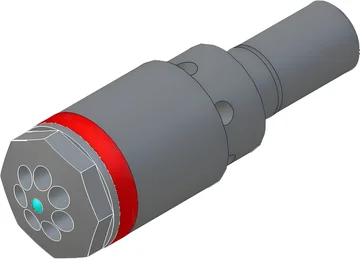

MDP™ Performance Non-Return Valve

- Lowest pressure drop design

- 6-7 year service life

- Universal polymer compatibility

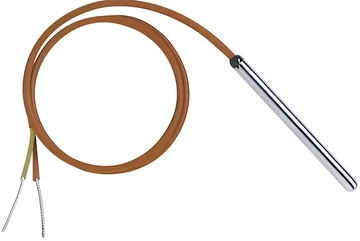

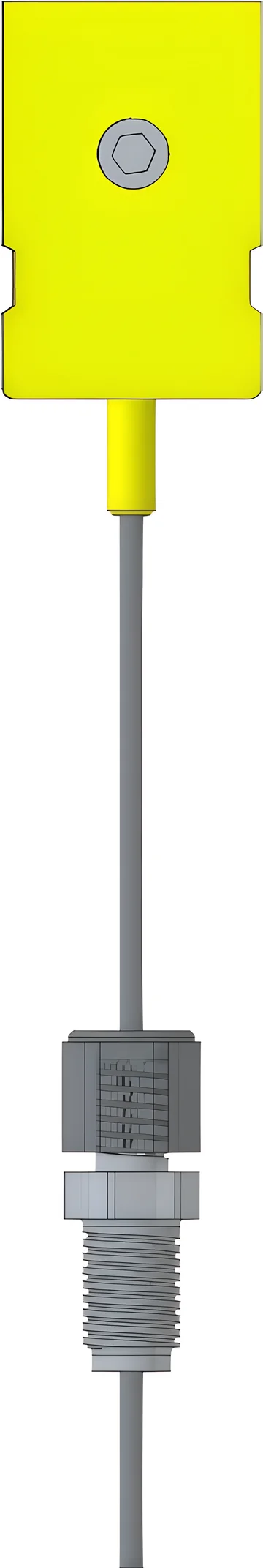

MD Plastics offers comprehensive precision molding solutions including patented shut-off valves, temperature sensors, plasticating systems, and monitoring equipment. Our high-performance components ensure optimal injection molding processes with enhanced quality control, reduced scrap rates, and improved productivity for automotive, medical, and industrial manufacturing applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 15 results

What is precision molding?

Precision molding is a manufacturing process that creates highly accurate plastic parts with tight tolerances using advanced injection molding technologies and specialized components.

What are the three types of molding?

How much does it cost to have an injection mold made?

What are the benefits of using patented shut-off valves?

How do temperature sensors improve molding quality?

What maintenance is required for precision molding equipment?

Can your systems retrofit existing injection molding machines?

Talk to our experts for custom solutions and tailored guidance.

High-precision plastic components for vehicle interiors, exteriors, and engine compartments requiring strict quality standards.

Sterile plastic components and precision molded parts for medical devices with stringent regulatory requirements.

Plastic housing components and electronic enclosures requiring precise dimensions and surface finish quality.

High-performance components for industrial applications including extrusion, blow molding, and specialty processing.

Talk to our experts for custom solutions and tailored guidance.

Over 25 years developing cutting-edge plasticating technologies with 12+ patents for enhanced molding performance and quality.

Direct consultation with founder Mike Durina and technical team for custom solutions tailored to your specific requirements.

Trusted by industry leaders like Foxconn, TE Connectivity, and Boston Scientific for reliable, high-performance molding components.

Connect with our technical team for custom solutions and pricing. Expect personalized guidance within 24 hours.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com