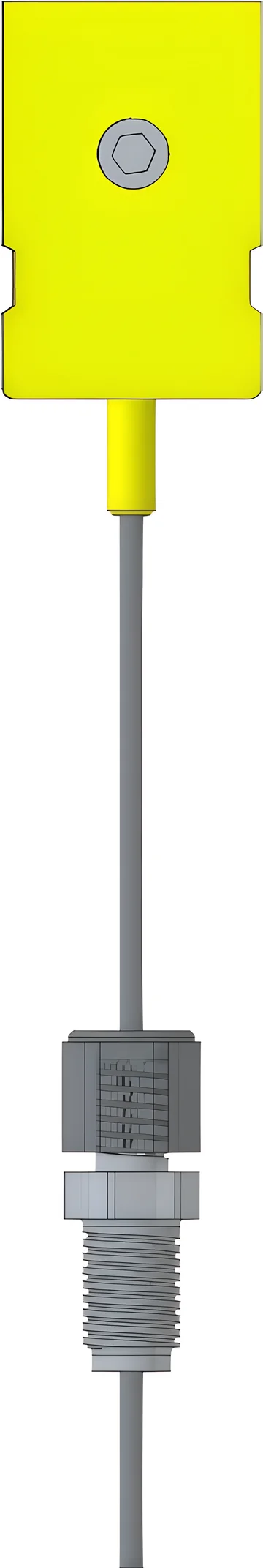

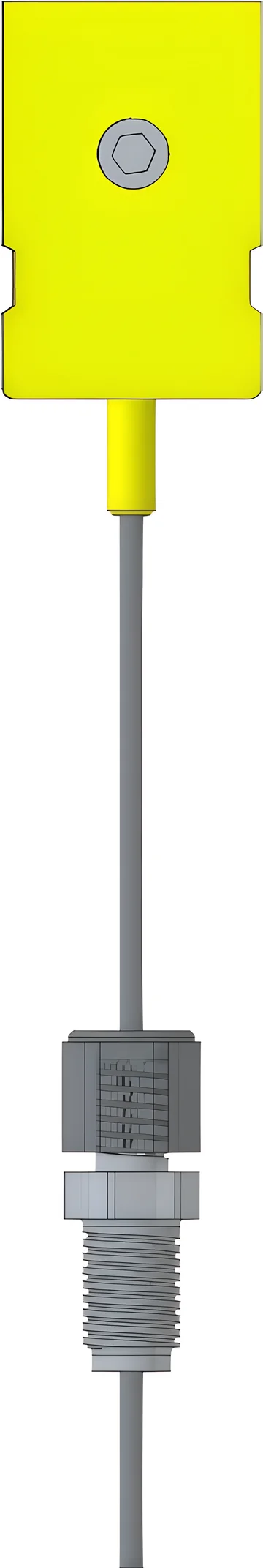

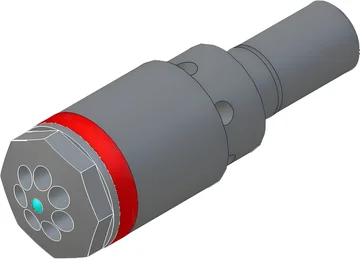

Temp-Sense™ Dynisco Style

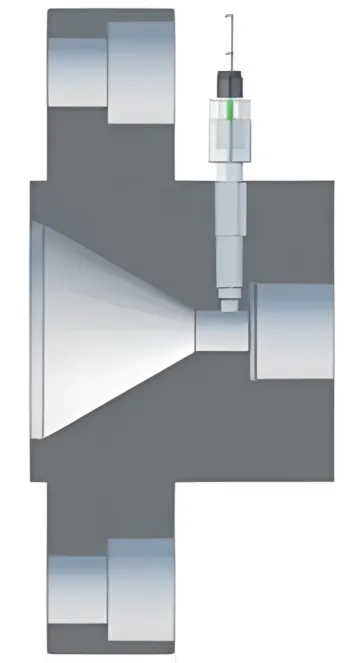

- Fits Dynisco ports & adapters

- Withstands up to 20,000 psi

- Made in the United States

ISO 9001:2015

U.S. Patent 7,585,166

U.S. Patent 6,649,095

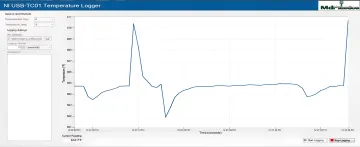

Our comprehensive mold cooling components catalog features advanced temperature monitoring systems and sensors for injection molding and extrusion processes. These patented solutions provide real-time melt temperature measurement, process optimization, and quality control to enhance production efficiency and reduce scrap rates across automotive, medical device, and electronics manufacturing applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

What is the cooling system in a mold?

A mold cooling system circulates coolant through channels to regulate temperature, ensuring consistent part quality and reducing cycle times in injection molding processes.

What are the cooling channels in mold?

What are the different types of cooling in mold?

How accurate are Temp-Sense™ sensors for melt temperature measurement?

Can the Melt-Profiler™ II System monitor multiple temperature zones simultaneously?

What pressure and temperature ranges can these sensors withstand?

Are these temperature monitoring systems compatible with existing molding equipment?

Talk to our experts for custom solutions and tailored guidance.

Real-time melt temperature monitoring ensures consistent quality for injection molded automotive components and plastic parts production.

Precision temperature control and validation for sterile plastic components requiring strict quality standards and regulatory compliance.

Optimized process control for plastic housing components and electronic enclosures with tight dimensional tolerances.

Advanced temperature monitoring for extrusion and injection molding operations requiring consistent quality and reduced scrap rates.

Talk to our experts for custom solutions and tailored guidance.

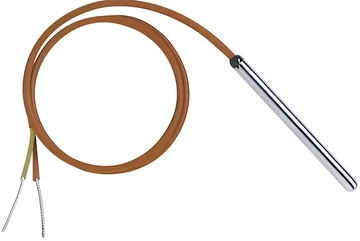

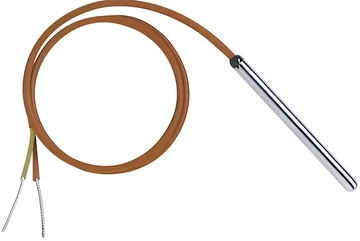

Our micro-bead sensing technology delivers ±1°C accuracy and sub-second response times, backed by U.S. Patents #7,585,166 and #6,649,095, ensuring unmatched real-time melt temperature measurement for optimal process control.

Founded in 1999 by plastics engineering expert Mike Durina with 40+ years of experience, we combine deep technical knowledge with disciplined innovation to solve complex plasticating challenges and improve profitability for injection molders.

From sensor selection and custom configuration to installation guidance and ongoing technical consultation, our expert team provides comprehensive support to ensure optimal performance and maximum return on investment for your operations.

Submit your requirements and our technical experts will respond within 24 hours with application-specific recommendations and custom quotes.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com