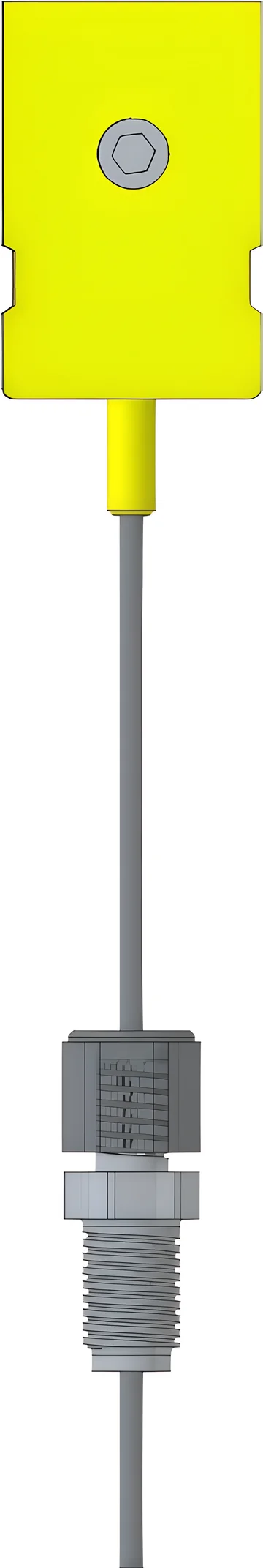

MDP™ Performance Non-Return Valve

- Lowest pressure drop in industry

- 6-7 year extended service life

- Universal polymer compatibility

US Patent Protection

ISO 9001:2015

Comprehensive injection equipment and supplies featuring patented shut-off valves, temperature sensors, monitoring systems, and plasticating components. Designed for injection molding, extrusion, and specialized applications requiring precise control, enhanced mixing, and real-time monitoring for optimal processing efficiency.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 15 results

What types of injection equipment does MD Plastics offer?

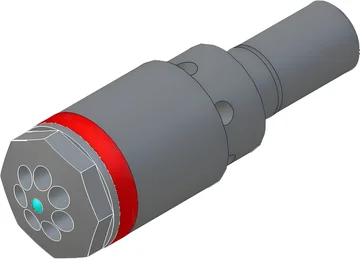

We manufacture shut-off valves, temperature sensors, monitoring systems, plasticating barrels, screws, and complete injection systems with patented technologies.

Are MD Plastics products compatible with existing injection molding machines?

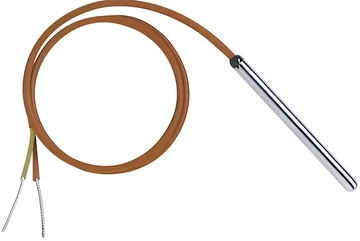

What temperature ranges can your sensors handle?

How accurate are your temperature monitoring systems?

What materials are compatible with your injection equipment?

Do you provide technical support and installation assistance?

What industries benefit most from your injection equipment?

Talk to our experts for custom solutions and tailored guidance.

Precision injection equipment for automotive plastic components requiring consistent quality and durability

Sterile plastic components and precision molding equipment for critical medical applications

Advanced injection equipment for plastic housing components and electronic device manufacturing

Robust injection and extrusion equipment for high-volume industrial plastic processing operations

Talk to our experts for custom solutions and tailored guidance.

Eight patents including revolutionary Mini-Shut™, Posi-Melt™, and Inject-EX™ technologies delivering proven performance advantages for injection molders worldwide.

Founded by Mike Durina with decades of plasticating experience, providing technical knowledge and custom solutions for optimal process control.

Real-time monitoring capabilities with Melt-Profiler™ and Temp-Sense™ systems ensuring consistent part quality and reduced scrap rates.

Connect with our technical team for personalized equipment recommendations and custom solutions. Quick response guaranteed.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com