Barrel Blitz Universal Purging Compound

- Universal compatibility all processes

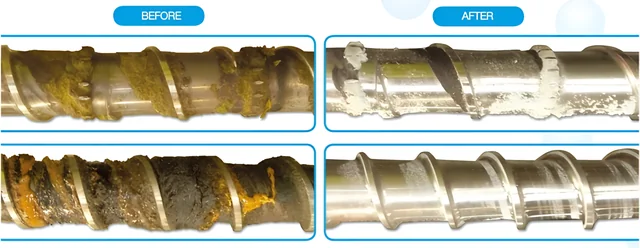

- Deep-clean next-gen technology

- Easy color and material changes

Industry Tested

Made in USA

Industrial injection mold cleaners and degreasers engineered to remove carbon deposits, facilitate color changes, and maintain optimal equipment performance. Our mechanical and chemical purging compounds deliver superior cleaning efficiency with reduced material usage and faster processing times across injection molding, extrusion, and blow molding operations.

What's the difference between mechanical and chemical purging compounds?

Mechanical compounds use physical scrubbing action while chemical compounds use surfactants for cleaning different contamination levels.

How much purging compound do I need for a color change?

Can these cleaners work with heat-sensitive materials?

What temperature range do your purging compounds cover?

How long does carbon deposit removal take?

Are your purging compounds safe for food-grade applications?

Do you provide technical support for application guidance?

Talk to our experts for custom solutions and tailored guidance.

Purging compounds for injection molded automotive components with efficient color changes and contamination removal.

Sterile plastic component production with contamination-free purging for critical medical applications.

Precision cleaning for plastic housing production ensuring defect-free electronic component manufacturing.

Comprehensive purging solutions for extrusion operations and multi-process plastic manufacturing facilities.

Talk to our experts for custom solutions and tailored guidance.

Founded in 1999, we bring decades of injection molding expertise and eight patented innovations to every solution we deliver.

Our purging compounds work first time, every time with proven performance across all applications and temperature ranges.

Direct access to our engineering team with comprehensive application guidance and custom solution consultation available.

Connect with our technical team for personalized purging compound recommendations and application-specific guidance.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com