High Performance Plasticating Barrels

- Bimetallic Construction Design

- Precision Honed Close Tolerance

- Abrasion & Corrosion Resistant

Made in USA

Patent Holder

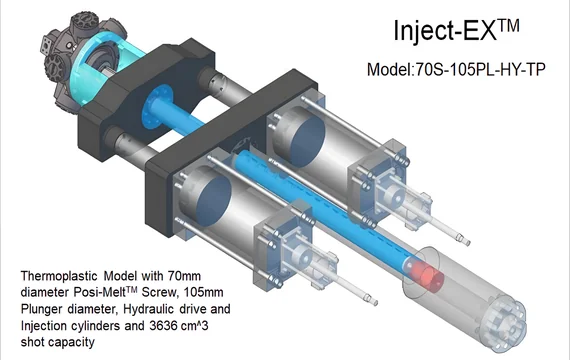

Industrial injection molding barrels engineered for superior performance in plastics processing. Our high-performance plasticating barrels feature bimetallic construction with precision-honed tolerances, designed for injection molding, extrusion, blow molding, and LSR applications across diverse manufacturing environments.

What is a barrel in injection molding?

An injection molding barrel is the heated cylinder that melts and conveys plastic material from the hopper to the mold cavity.

How to calculate injection molding barrel capacity?

What materials are used in barrel construction?

What size range do you offer for injection molding barrels?

Do you provide custom barrel design services?

What applications are these barrels suitable for?

Do you offer barrel repair and relining services?

Talk to our experts for custom solutions and tailored guidance.

Precision barrels for injection molded automotive components requiring tight tolerances and durability

High-precision barrels for sterile plastic medical components with stringent quality requirements

Reliable barrels for plastic housing components in electronics manufacturing with consistent quality

Heavy-duty barrels for demanding industrial plastic processing environments requiring maximum durability

Talk to our experts for custom solutions and tailored guidance.

Deep technical expertise with patented innovations and proven track record in plasticating component design and manufacturing excellence.

Owner Mike Durina personally designs barrels to fit specific machine requirements with proprietary design software for optimal performance.

Expert consultation, application review, repairs and relining services backed by dedicated technical team and industry knowledge.

Connect with our technical team for custom barrel design, application review, and optimum bore selection for your specific requirements.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com