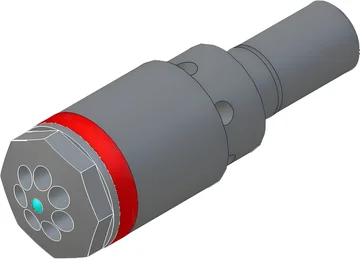

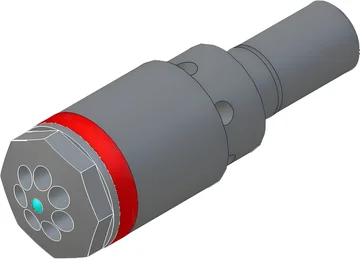

MDP™ Performance Non-Return Valve

- Lowest pressure drop industry

- 6-7 year service life

- Universal polymer compatibility

US Patent Protected

Manufacturing Excellence

MD Plastics specializes in precision injection molding screw barrels and plasticating systems designed to maximize performance, efficiency, and profitability. Our bimetallic construction and patented technologies deliver superior melt quality, extended equipment life, and reduced downtime for injection molding operations across diverse industries.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 8 results

What is a barrel in an injection molding machine?

A barrel is the heated cylinder component that houses the plasticating screw and melts polymer pellets into homogeneous melt for injection.

What is screw injection molding?

What is the price of 1000 ton injection molding machine?

How do bimetallic barrels improve performance?

What size range do your barrels cover?

How often should injection molding screws be replaced?

Can you retrofit existing injection molding equipment?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molding components for interior, exterior, and under-hood automotive applications

Sterile plastic components and precision molding for medical devices and healthcare applications

Plastic housing components and precision parts for electronic devices and consumer products

Heavy-duty plasticating systems for industrial plastic processing and manufacturing operations

Talk to our experts for custom solutions and tailored guidance.

Eight patents including revolutionary Inject-EX™, Mini-Shut™, and Posi-Melt™ technologies that deliver measurable performance improvements and competitive advantages.

Founded by Mike Durina with deep plasticating expertise, we've helped thousands of molders improve profitability through better component design and engineering.

Direct consultation with our founder and proprietary design software ensure optimal barrel bore selection and screw geometry for your specific applications.

Connect with our technical team for custom barrel and screw design. Receive personalized recommendations within 24 hours.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com