Posi-Melt™ Extrusion Screws

- Custom flight geometry design

- Low pressure drop operation

- Complete pressurization

Patented Technology

Advanced extruder screws and barrels engineered for superior plastic processing performance. Our patented Posi-Melt™ technology delivers up to 60% increased plastic exposure for uniform mixing, faster changeovers, and reduced manufacturing costs across injection molding, extrusion, and blow molding applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

What are the different types of extruder screws and barrels?

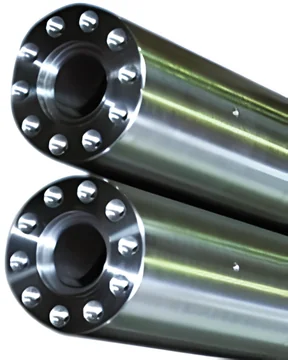

Md Plastics Inc offers several specialized types including Mixing Screws with advanced dispersive mixing technology, Barrier Screws featuring single-channel design for fast purging, Extrusion Screws with custom flight geometry, Multipurpose Screws with un-tangential flight design as drop-in OEM replacements, and Plasticating Barrels with bimetallic construction and precision honed tolerance up to 260 inches in length.

What is an extruder barrel?

What makes Posi-Melt™ technology different from standard extruder screws?

How do I know which extruder screw type is right for my application?

What industries benefit most from upgraded extruder screws and barrels?

Can I get custom screw designs for unique processing challenges?

What is the advantage of bimetallic barrel construction?

How do these extruder components reduce manufacturing costs?

Talk to our experts for custom solutions and tailored guidance.

Precision extruder screws for injection molded automotive components requiring consistent quality.

High-performance barrels and screws for sterile plastic medical device component production.

Advanced mixing screws for plastic housing components in consumer electronics manufacturing.

Heavy-duty extruder components for continuous industrial plastic processing and production.

Talk to our experts for custom solutions and tailored guidance.

Founded by industry veteran with 8 patents and decades of plasticating expertise, delivering proven performance solutions.

Proprietary designs increase plastic exposure by 60% for superior mixing, faster changeovers, and reduced manufacturing costs.

Owner Mike Durina personally designs solutions with direct technical consultation and comprehensive support services.

Connect with our technical team for custom screw and barrel solutions. Expect prompt response from our plasticating experts.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com