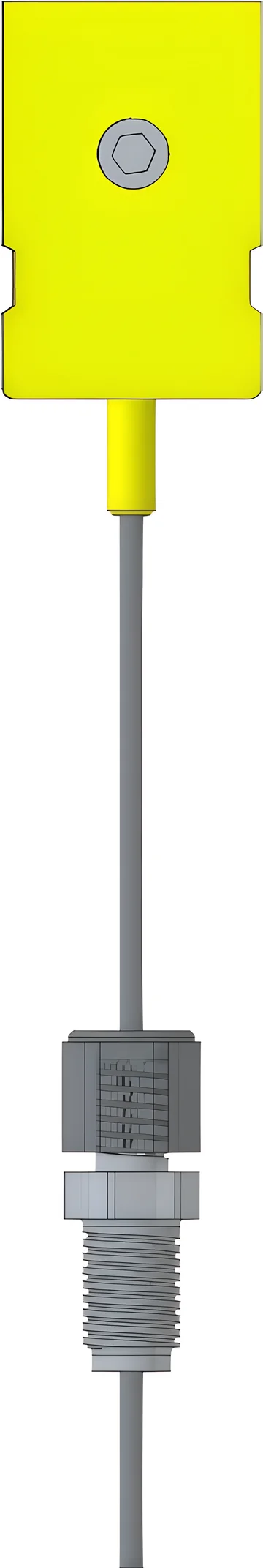

Temp-Sense™

- Real-time monitoring capability

- Multiple model configurations

- Industrial grade durability

US Patent Protected

ISO 9001:2015

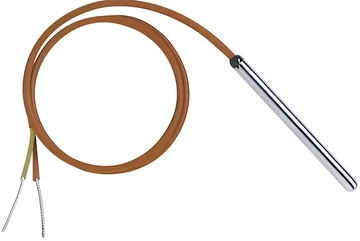

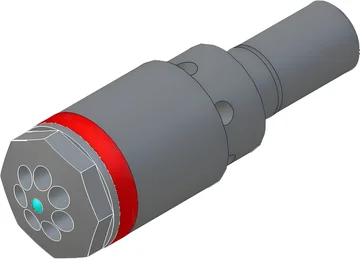

Comprehensive injection molding solutions including patented screws, barrels, shut-off valves, temperature sensors, and monitoring systems. MD Plastics delivers innovative plasticating components with proven performance for enhanced productivity, reduced scrap rates, and superior melt quality in industrial manufacturing applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 17 results

What temperature ranges do MD Plastics sensors support?

Our Temp-Sense™ sensors operate up to 450°C with ±1°C accuracy for precise real-time monitoring.

How does the Mini-Shut™ technology eliminate drooling?

What makes Posi-Melt™ screws more efficient than standard designs?

Can your components retrofit existing injection molding machines?

What is the typical service life of your plasticating components?

Do you provide custom design services for specific applications?

What technical support do you offer with your products?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components for automotive applications requiring consistent quality and performance.

Sterile plastic components and precision molding for critical medical device applications.

High-precision plastic housing components for electronic devices and consumer products.

Heavy-duty plasticating solutions for demanding industrial manufacturing and processing environments.

Talk to our experts for custom solutions and tailored guidance.

Eight patented technologies including Posi-Melt™ screws, Mini-Shut™ nozzles, and Melt-IQ™ systems deliver proven performance improvements.

Founded in 1999 by Mike Durina with decades of plastics engineering expertise, serving leading manufacturers like Foxconn and Boston Scientific.

Direct consultation with founder Mike Durina ensures custom-engineered components tailored to specific machine requirements and applications.

Connect with our technical team for custom component design, application guidance, and competitive quotes. Direct access to 25+ years of expertise.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com