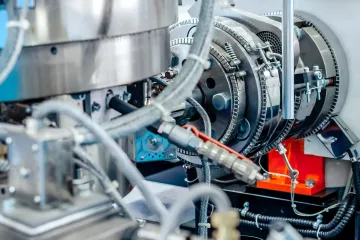

High Performance Plasticating Barrels

- Bimetallic bonded construction

- Precision honed tolerances

- 14-250mm bore size range

US Patent Holder

Made in USA

High-performance extrusion barrels designed for injection molding, extrusion, and blow molding applications. Featuring bimetallic construction with precision-honed tolerances and abrasion-resistant liners, these industrial-grade barrels deliver superior durability, energy efficiency, and process control. Manufactured in the USA with custom design capabilities for sizes ranging from 14mm to 260mm.

What is an example of extrusion?

Extrusion is a manufacturing process where heated plastic material is forced through a barrel and die to create continuous profiles like pipes, sheets, or films.

What are the benefits of bimetallic barrel construction?

What barrel sizes are available for injection molding machines?

Can you retrofit existing injection molding presses with new barrels?

What materials are compatible with these plasticating barrels?

How do I select the right barrel for my application?

What is the typical lead time for custom plasticating barrels?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded components for vehicle interiors, exteriors, and under-hood applications with consistent quality.

Sterile plastic components for medical devices requiring ultra-precise shot control and validated process consistency.

High-quality plastic housing and structural components with tight tolerances for electronic devices and appliances.

Heavy-duty extrusion and blow molding operations for industrial plastics processing with maximum uptime requirements.

Talk to our experts for custom solutions and tailored guidance.

Since 1999, we've delivered innovative plasticating solutions backed by decades of industry expertise and eight patented technologies.

Owner Mike Durina personally designs barrels using proprietary software that calculates heat transfer, shear rates, and pressure profiles for your exact specifications.

Our bimetallic barrels deliver extended equipment life, reduced scrap, and improved melt quality with measurable cost savings for processors worldwide.

Our technical team will review your application requirements and provide expert recommendations with a detailed quote within 24-48 hours.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com