Melt-IQ™ System

- Real-time temperature monitoring

- Good/Bad part quality prediction

- VP switch point control

ISO 9001:2015

U.S. Patent 7,585,166

U.S. Patent 6,649,095

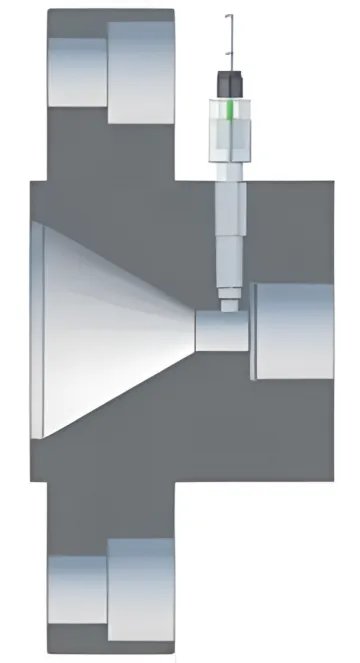

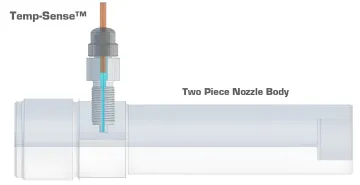

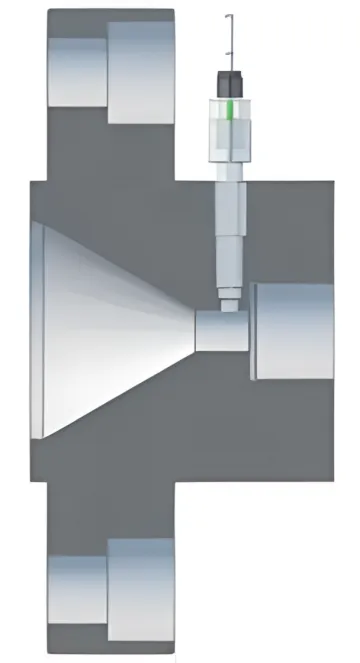

MD Plastics offers precision plastic melt monitoring systems that deliver real-time temperature analysis and process control for injection molding operations. Our patented sensor technologies and intelligent monitoring platforms enable manufacturers to optimize processing conditions, reduce scrap rates, and ensure consistent part quality through continuous melt profiling and data-driven insights.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 7 results

What is the accuracy of MD Plastics temperature sensors?

Our patented micro-bead sensors deliver ±1°C accuracy with response times under 1 second, providing the most precise melt temperature measurement available for injection molding applications.

How do melt monitoring systems reduce scrap rates?

Can these systems retrofit existing injection molding machines?

What is the difference between Melt-IQ™ and Melt-Profiler™ systems?

What temperature range do the sensors support?

How quickly can I expect ROI from a melt monitoring system?

Do you provide installation and training support?

Talk to our experts for custom solutions and tailored guidance.

Precision melt monitoring for injection molded automotive components ensures consistent quality and dimensional accuracy in high-volume production environments.

Real-time temperature profiling systems validate sterile plastic component production with documented process control for regulatory compliance.

Advanced sensor technology monitors melt conditions for plastic housing components requiring tight tolerances and superior surface finish quality.

Robust monitoring systems withstand demanding extrusion and injection molding environments while delivering continuous process optimization.

Talk to our experts for custom solutions and tailored guidance.

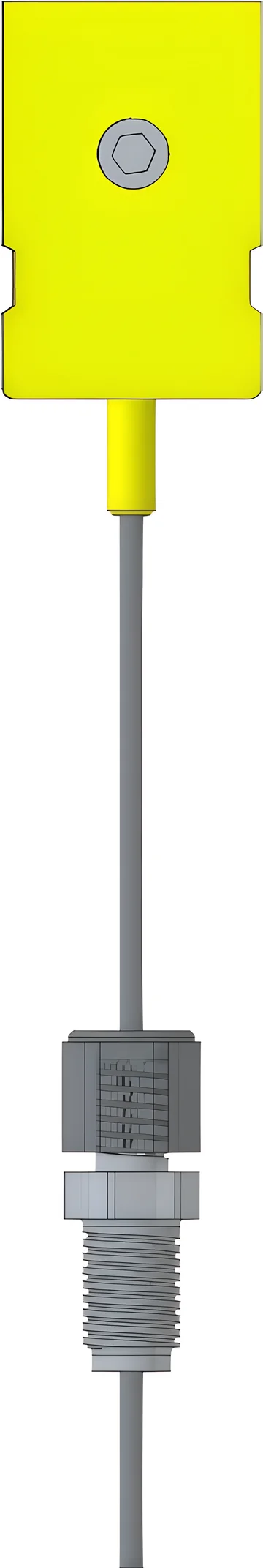

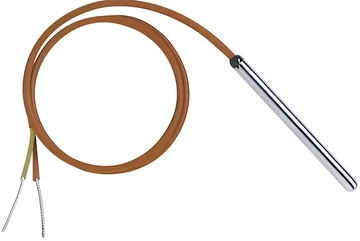

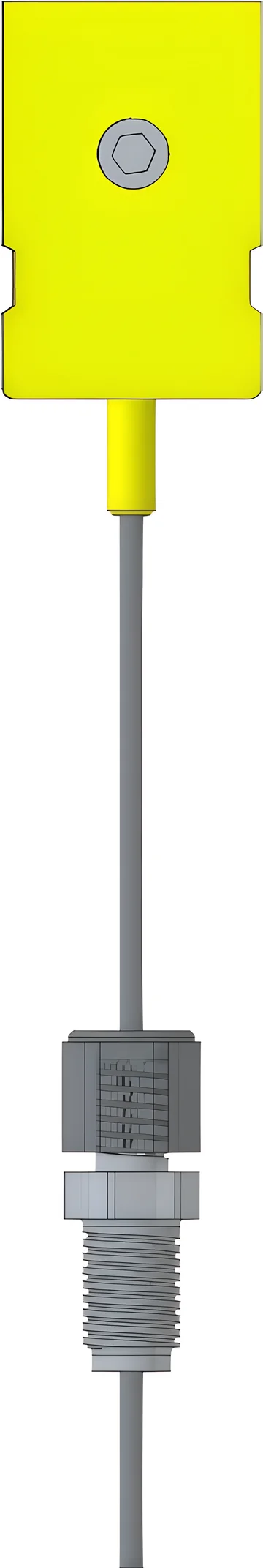

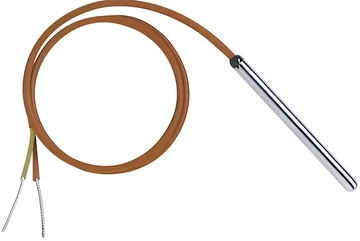

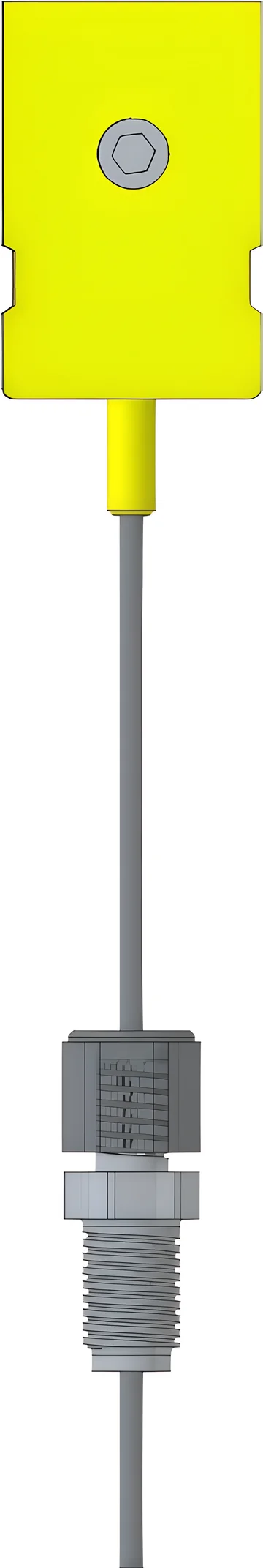

Our proprietary micro-bead sensors deliver unmatched accuracy (±1°C) with sub-second response times, protected by multiple U.S. patents for proven innovation and reliability.

Founded in 1999 by industry veteran Mike Durina, we bring decades of plasticating knowledge and eight patented innovations to help injection molders maximize profitability.

From standalone sensors to comprehensive monitoring platforms like Melt-IQ™ and Melt-Profiler™, we provide end-to-end solutions with installation support and free software upgrades.

Request a quote and our technical experts will help you select the right melt monitoring solution. Expect a response within one business day with personalized recommendations.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com