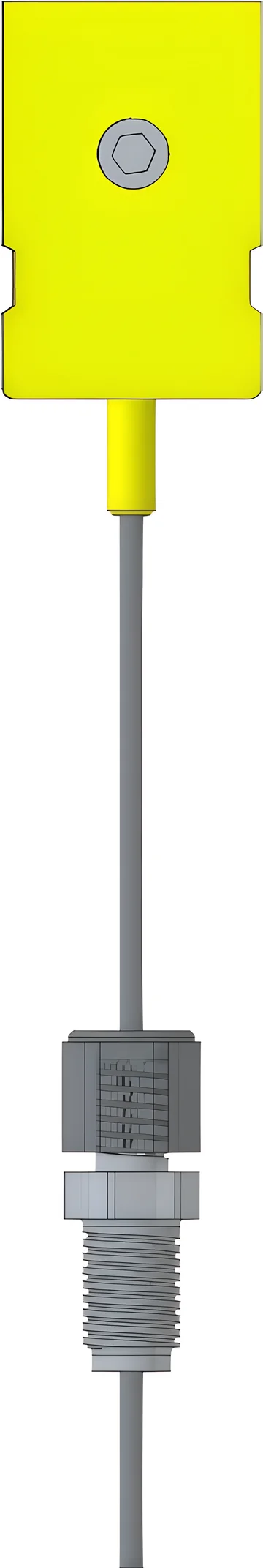

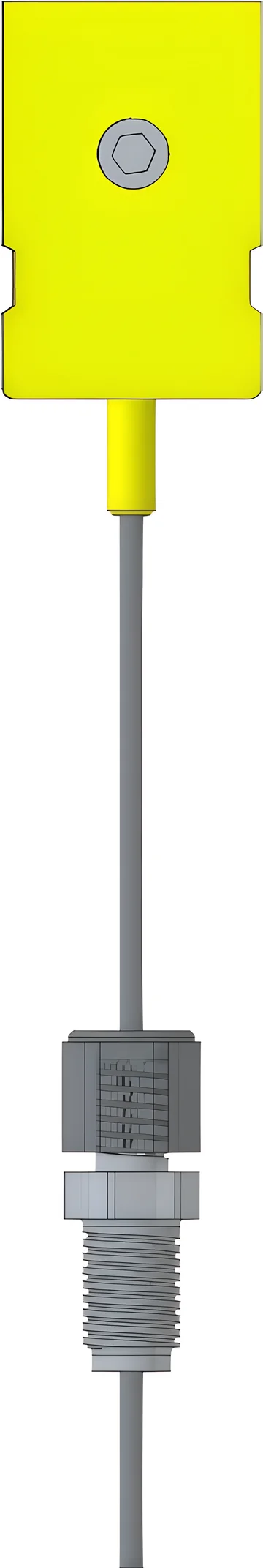

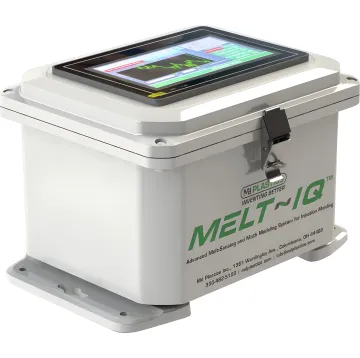

Melt-IQ™ System

- Real-time quality prediction

- VP switch point control

- 24-bit precision ADC processor

US Patent Technology

ISO 9001:2015

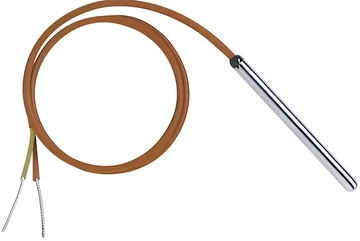

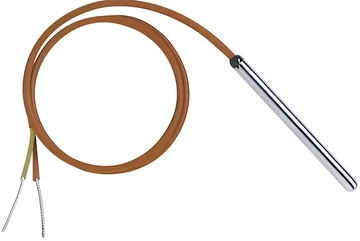

Plastic melt monitors deliver real-time temperature and process monitoring for injection molding and extrusion operations. Our patented Temp-Sense™ technology and advanced monitoring systems provide precise melt temperature measurement, quality prediction, and process optimization to reduce scrap rates and improve part consistency across automotive, medical device, and industrial manufacturing applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 7 results

What is the accuracy of Temp-Sense™ melt sensors?

Temp-Sense™ sensors deliver ±1°C accuracy with response times under 1 second, providing precise real-time melt temperature data for optimal process control and quality assurance.

Can melt monitors work with existing injection molding equipment?

How do melt monitors reduce scrap rates?

What industries benefit most from melt monitoring systems?

What is the difference between Melt-IQ™ and Melt-Profiler™ II?

How long do Temp-Sense™ sensors last in production?

Is technical support included with melt monitoring systems?

Talk to our experts for custom solutions and tailored guidance.

Precision melt monitoring ensures consistent quality for injection molded automotive components and plastic parts production with real-time process control.

Advanced temperature monitoring systems provide the precision and documentation required for sterile plastic components and FDA-compliant molding operations.

Real-time melt temperature tracking enables consistent production of plastic housing components with tight tolerances for electronic devices and assemblies.

Comprehensive monitoring solutions optimize extrusion and injection molding operations for industrial applications requiring high throughput and consistent quality.

Talk to our experts for custom solutions and tailored guidance.

Eight patents in plasticating and melt monitoring technology, including revolutionary Temp-Sense™ micro-bead sensors and Melt-IQ™ systems that deliver unmatched accuracy and real-time quality prediction for superior process control.

Since 1999, we've helped injection molders improve profitability through innovative plasticating solutions. Our founder's 40+ years of experience ensures you get proven, reliable technology backed by deep industry knowledge.

From installation guidance to custom system design, our expert team provides comprehensive support including free software upgrades, phone consultations, and direct access to engineering expertise for optimal system performance.

Connect with our technical team to discuss your specific application. We'll help you select the right monitoring system and provide a custom quote tailored to your process requirements.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com