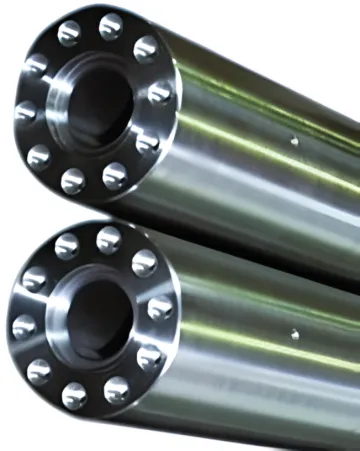

High Performance Plasticating Barrels

- Bimetallic bonded construction

- Precision honed tolerance fit

- Manufactured in United States

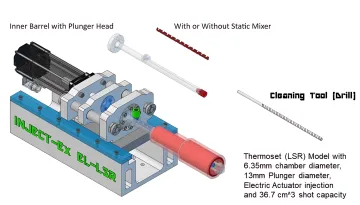

Browse our complete line of silicone rubber screw barrels and plasticating systems engineered for LSR processing and injection molding. These advanced systems feature patented Posi-Melt™ technology, precision-honed bimetallic construction, and real-time monitoring capabilities. Designed for superior melt quality, faster changeovers, and extended equipment life across demanding silicone rubber applications. Over 25 years of manufacturing excellence from MD Plastics.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

What makes silicone rubber screw barrels different from standard plasticating systems?

Silicone rubber screw barrels feature specialized LSR-compatible materials, patented mixing geometries, and corrosion-resistant construction designed specifically for thermoset liquid silicone rubber processing applications.

How does the Posi-Melt™ technology improve LSR processing performance?

What size range of silicone rubber screw barrels are available?

Can these systems retrofit existing injection molding machines?

What industries benefit most from advanced silicone rubber screw barrels?

How does bimetallic construction extend barrel service life?

What technical support is available for custom screw barrel design?

Talk to our experts for custom solutions and tailored guidance.

Precision silicone rubber screw barrels engineered for sterile LSR components requiring consistent melt quality and tight tolerances.

High-performance plasticating systems for automotive silicone rubber seals, gaskets, and injection molded components.

Precision LSR processing equipment for consumer electronics housing, seals, and silicone rubber protective components.

Robust plasticating systems designed for industrial silicone rubber applications requiring superior durability and uptime.

Talk to our experts for custom solutions and tailored guidance.

Our proprietary screw designs increase plastic exposure by 60% for superior melt uniformity, faster changeovers, and reduced scrap in LSR applications.

Since 1999, we've engineered advanced plasticating solutions backed by 8 patents and decades of injection molding expertise from our founder Mike Durina.

Direct consultation with our owner for custom screw barrel design, technical optimization software, and end-to-end support from design to installation.

Submit your requirements and our technical team will respond within 24 hours with custom recommendations, specifications, and competitive pricing.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com