Inject-EX™ Plasticating System

- Stationary screw eliminates defects

- Ultra precise shot control technology

- Made in United States

ISO 9001:2015

U.S. Patented Technology

High precision automatic industrial plastic melt machines designed to optimize injection molding and extrusion processes. Our comprehensive range includes advanced plasticating systems, mixing screws, temperature sensors, and shut-off valves engineered for superior melt quality, precise shot control, and enhanced productivity across all polymer types and machine sizes.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 15 results

What is a high precision automatic industrial plastic melt machine?

It's a comprehensive system of plasticating components including mixing screws, barrels, sensors, and control valves that optimize injection molding and extrusion processes for superior melt quality and precision.

How does the Posi-Melt™ technology improve melt quality?

What are the benefits of real-time melt temperature monitoring?

Can these systems be retrofitted to existing equipment?

What machine sizes are supported by these systems?

How long is the typical service life of these components?

What technical support is available for installation and operation?

Talk to our experts for custom solutions and tailored guidance.

Precision injection molded plastic components for automotive interiors, exteriors, and under-hood applications requiring consistent quality and high-volume production.

Sterile plastic components and precision molding for medical devices, surgical instruments, and diagnostic equipment with stringent quality standards.

High-precision plastic housing components, enclosures, and internal parts for smartphones, computers, and electronic devices requiring tight tolerances.

Large-scale extrusion and injection molding for industrial plastic products, packaging, pipes, profiles, and engineered components across diverse applications.

Talk to our experts for custom solutions and tailored guidance.

Founded in 1999 by Mike Durina, we combine decades of plastics engineering expertise with cutting-edge design software and patented technologies to deliver measurable profitability improvements for injection molders worldwide.

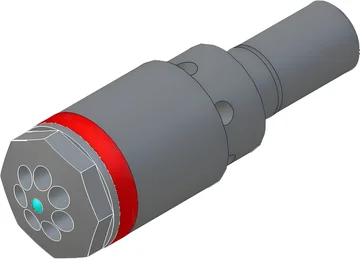

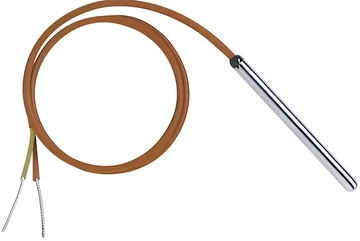

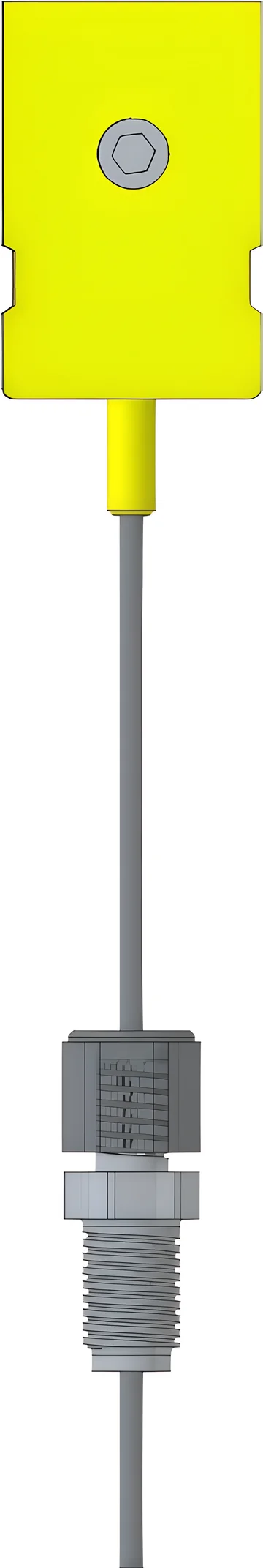

Our portfolio includes 8+ U.S. patents covering revolutionary plasticating systems like Inject-EX™, Posi-Melt™ screws, Mini-Shut™ nozzles, and real-time Melt-Profiler™ monitoring systems that set industry standards for precision and efficiency.

Direct consultation with founder Mike Durina and our expert team ensures custom-engineered solutions tailored to your specific requirements, backed by comprehensive installation support and ongoing technical guidance at every stage.

Contact us for a custom quote and technical consultation. Our team will help you select the right plasticating components to optimize your injection molding or extrusion process.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com