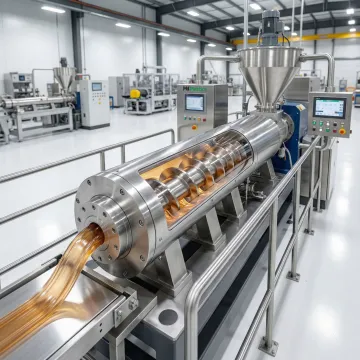

Posi-Melt™ MB Barrier Screws

- 60% increased barrel exposure

- Patented MB barrier geometry

- Fast purging performance

MD Plastics Inc. manufactures American-made feed screws and barrels engineered for precision plasticating in injection molding and extrusion. Our patented Posi-Melt™ technology, high-performance bimetallic barrels, and advanced mixing systems deliver superior melt quality, faster changeovers, and extended equipment life across thermoplastic and LSR applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

What makes Posi-Melt™ screws different from standard feed screws?

Posi-Melt™ screws use patented flight geometry that increases plastic exposure to the barrel wall by up to 60%, delivering superior melt uniformity and faster changeovers compared to conventional designs.

What size range do your American feed screws and barrels cover?

Can your screws and barrels handle abrasive or corrosive materials?

Do you offer custom screw designs for specific applications?

What is the typical lead time for custom screws and barrels?

Are your products compatible with existing injection molding machines?

What technical support do you provide after purchase?

Talk to our experts for custom solutions and tailored guidance.

Precision feed screws and barrels for injection molding automotive components with consistent quality and fast cycle times.

Sterile-grade plasticating systems delivering the melt uniformity required for precision medical component molding.

Advanced mixing screws ensuring color consistency and dimensional accuracy for plastic housings and enclosures.

Patented extrusion screws optimizing throughput and melt quality for pipe, profile, sheet, and film production.

Talk to our experts for custom solutions and tailored guidance.

Our proprietary screw geometry increases plastic exposure to the barrel wall by up to 60%, delivering superior melt uniformity and reduced scrap rates across all polymer types.

Since 1999, we've engineered American-made plasticating solutions trusted by global leaders like Foxconn, TE Connectivity, and Boston Scientific for injection molding and extrusion precision.

Direct consultation with founder Mike Durina and our technical team ensures your screws and barrels are optimized for your specific materials, throughput goals, and machine configurations.

Our technical team will review your application and recommend the optimal screw and barrel configuration. Expect a detailed response within one business day.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com