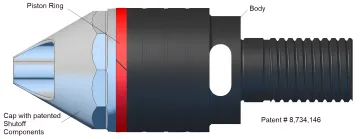

Mini-Shut™ Automatic Shut-Off Nozzle

- Instant automatic shutoff technology

- Universal nozzle body compatibility

- Minimal pressure loss design

US Patent Technology

Made in USA

Positive shut-off nozzles for industrial machinery eliminate drooling and stringing in injection molding operations. Our patented automatic shut-off technology provides instant, precise closure when melt flow stops, ensuring shot-to-shot consistency and reducing scrap rates. Compatible with all machine sizes and polymers, these shut-off valves improve cycle times, maintain optimal injection conditions, and work seamlessly with thermoplastics, LSR, and structural foam applications.

What is a positive shut-off nozzle?

A positive shut-off nozzle is an automatic valve that instantly stops material flow in injection molding when melt stops, eliminating drooling and stringing to ensure consistent part quality.

What is a shut-off nozzle?

How does the Mini-Shut™ automatic shutoff technology work?

What machine sizes are compatible with these shut-off nozzles?

Can shut-off nozzles be used with LSR and structural foam molding?

How do shut-off nozzles reduce scrap and improve part quality?

What materials are the shut-off nozzles made from?

Talk to our experts for custom solutions and tailored guidance.

Precise shutoff control for injection molded plastic components ensuring consistent part quality in high-volume production.

Sterile precision molding for medical components requiring shot-to-shot consistency and zero contamination from drooling.

High-quality plastic housing production with automatic shutoff preventing defects and maintaining tight tolerances.

Efficient processing of thermoplastics and difficult resins with minimal downtime and improved productivity.

Talk to our experts for custom solutions and tailored guidance.

Our proprietary Mini-Shut™ technology delivers instantaneous, precise shutoff, eliminating drooling and stringing while ensuring consistent part quality across every shot.

Founded in 1999, we bring decades of plasticating expertise with 8+ awarded patents, providing forward-thinking solutions that improve profitability and efficiency.

Our shut-off nozzles fit virtually all machine sizes from small to 400+ oz capacity and work with all polymers, thermoplastics, LSR, and difficult-to-process resins.

Request a quote and our technical team will respond within 24 hours with custom recommendations tailored to your machine configuration and processing requirements.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com