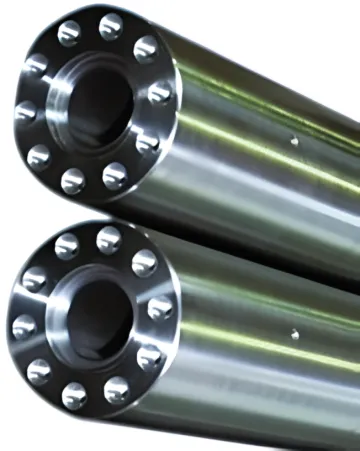

High Performance Plasticating Barrels

- Bimetallic bonded construction

- Precision honed close tolerance

- Made in USA

Patented Technology

Made in USA

MD Plastics manufactures professional-grade bimetallic screw barrels and plasticating systems for injection molding, extrusion, and blow molding applications. Our patented Posi-Melt™ technology delivers superior melt quality, enhanced mixing, and extended equipment life. From precision-honed barrels to advanced mixing screws, our solutions improve productivity while reducing scrap and downtime across automotive, medical, and industrial manufacturing.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

What makes bimetallic screw barrels superior to standard barrels?

Bimetallic construction bonds two different metals, creating a hard wear-resistant liner with high-strength steel backing for maximum durability and extended service life.

How does Posi-Melt™ technology improve melt quality?

What size range of screw barrels does MD Plastics manufacture?

Can your screws retrofit existing injection molding machines?

What materials are compatible with your plasticating systems?

How do I specify the right screw barrel for my application?

What after-sales support does MD Plastics provide?

Talk to our experts for custom solutions and tailored guidance.

High-performance screw barrels for precision injection molded automotive components requiring consistent quality and dimensional accuracy.

Precision plasticating systems delivering sterile, consistent plastic components for medical devices with stringent regulatory requirements.

Advanced mixing screws ensuring uniform melt quality for plastic housing components in consumer electronics with tight tolerances.

Durable bimetallic barrels for high-volume extrusion and compounding operations in demanding industrial environments.

Talk to our experts for custom solutions and tailored guidance.

Founded in 1999 by industry veteran Mike Durina, we've delivered cutting-edge plasticating solutions with eight patents and decades of engineering expertise driving profitability for manufacturers worldwide.

Our proprietary screw designs increase plastic exposure to barrel walls by up to 60%, delivering superior melt quality, faster changeovers, and reduced scrap across all polymer types.

Work directly with founder Mike Durina and our technical team using advanced design software to create optimized solutions tailored to your exact process requirements and machine specifications.

Get expert consultation from our technical team. We'll analyze your requirements and provide a tailored solution with competitive pricing and delivery timeline.

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com

For immediate assistance, feel free to give us a direct call at 3304825100 You can also send us a quick email at info@mdplastics.com