Technical Specifications at a Glance

Detailed specifications and technical parameters for the Posi-Shut™ Automatic Shut-Off Valve system.

DON'T JUST TAKE OUR WORD WATCH TO SEE HOW IT WORKS

Engineered for Maximum Performance

Advanced valve technology delivering superior process control and consistent quality for injection molding operations.

Precise Shutoff Control

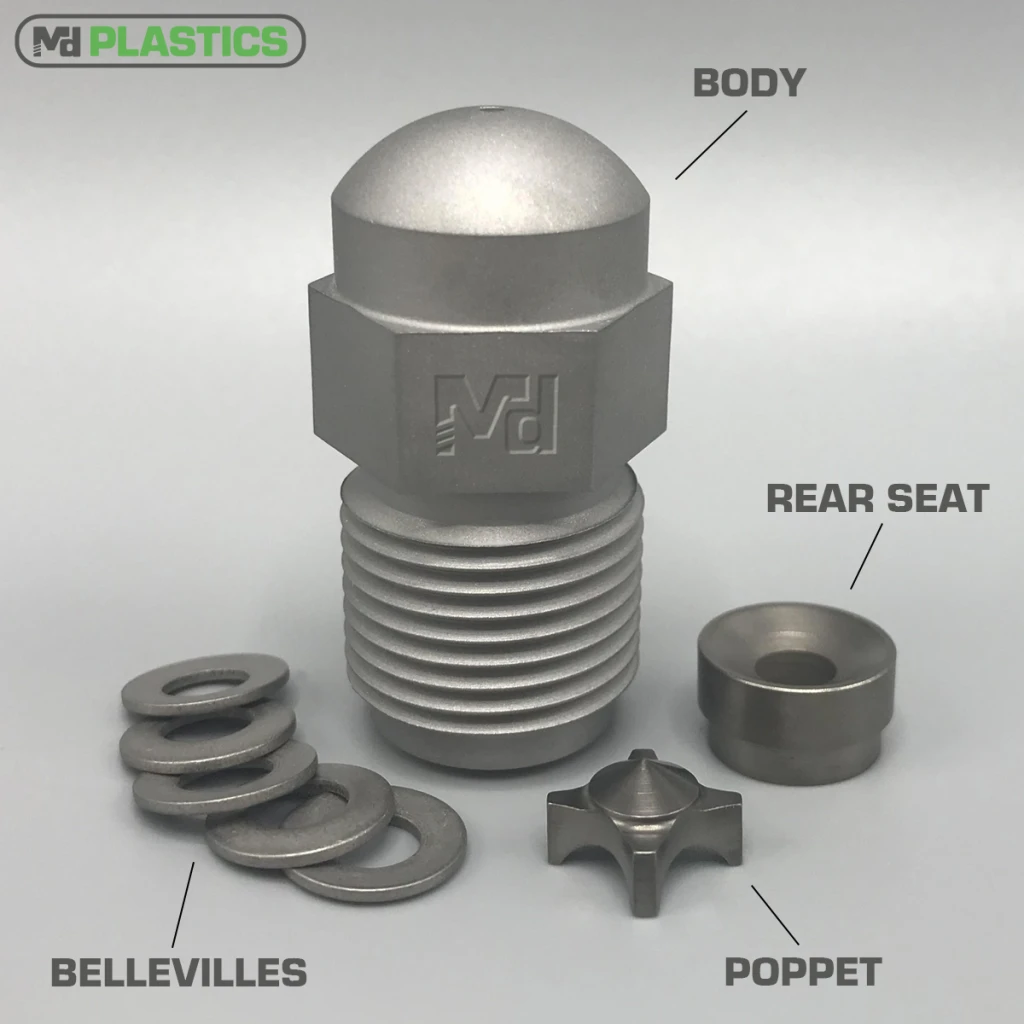

Mechanically operated poppet valve provides instantaneous and precise closure at sealing surface, ensuring shot-to-shot consistency and eliminating material waste through superior shutoff performance.

Independent Operation

Valve operates independently of screw movement, facilitating valve shut-off at melt recovery and eliminating the need for decompression while maintaining optimal process control throughout the molding cycle.

Patented Technology

Features patented Mini-Shut™ technology with replaceable shutoff cartridge (Patent #8734146), providing proven reliability and cost-effective maintenance for extended operational life and consistent performance.

Durable Construction

Standard construction utilizes wear-resistant heat-treated H13 tool steel with optional metallurgical and surface treatments available for extreme abrasion and corrosion environments, ensuring long-term durability.

Enhanced Productivity

Reduces scrap rates and reject rates while improving overall part quality, maximizing yield rates and increasing profit margins through consistent part-to-part weight control and superior process repeatability.

Versatile Applications

Compatible with most resins processed in injection molding including standard thermoplastics, LSR processing, structural foam molding, and difficult-to-process resins with customized design options available.

Frequently Asked Questions

What size range and materials are compatible with this valve?

The Posi-Shut™ valve is available in 50MM and up for thermoplastics, with customized design and size ranges available for Liquid Silicone Rubber (LSR) processing. It's compatible with most resins processed in injection molding, including standard thermoplastics and difficult-to-process resins.

How does the valve achieve such precise shutoff performance?

The valve uses Belleville springs to create kinetic energy that expedites valve closure, achieving instantaneous and precise closure at the sealing surface with each shot. This mechanical system ensures repeatable performance and consistent part-to-part weight control.

What construction materials and treatment options are available?

Standard construction uses wear-resistant heat-treated H13 tool steel. Metallurgical and surface treatment options are available for extreme abrasion and corrosion wear environments, ensuring optimal performance in demanding processing conditions.

Industries We Serve

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Medical Devices

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Consumer Electronics

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Additive Manufacturing

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Plastic Processing

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Complete Plasticating System Solutions

Discover our comprehensive range of advanced plasticating components designed to optimize your injection molding operations.

MDP™ Performance Non-Return Valve

Features patented design with low pressure drop, precise shutoff, and extended wear life of 6-7 years. Works with all polymers and sizes from 14-260mm with improved hydraulic design.

Mini-Shut™ Automatic Shut-Off Nozzle

Simple, cost-effective solution that eliminates melt-decompression, stringing, and drooling. Shuts off instantaneously with unique design allowing free flow with minimal pressure loss.

Inject-EX™ Plasticating System

Revolutionary system with stationary Posi-Melt™ screw providing consistent output-recovery time, ultra precise shot control with patented mechanical shut-off mechanism, and smaller footprint design.

Need Custom Engineering Solutions?

Connect with our technical experts for personalized valve design and application consultation services.

Let's Optimize Your Operations

Ready to experience the superior cleaning performance of Posi Shut Automatic Shut-Off Valve Blitz Universal? Contact our team for expert guidance and custom solutions.

For immediate assistance, call (330) 482-5100 or email us at [email protected]

For immediate assistance, call (330) 482-5100 or email us at [email protected]