ISO 9001:2015 Certified

ISO 9001:2015 Certified CE

Certified

CE

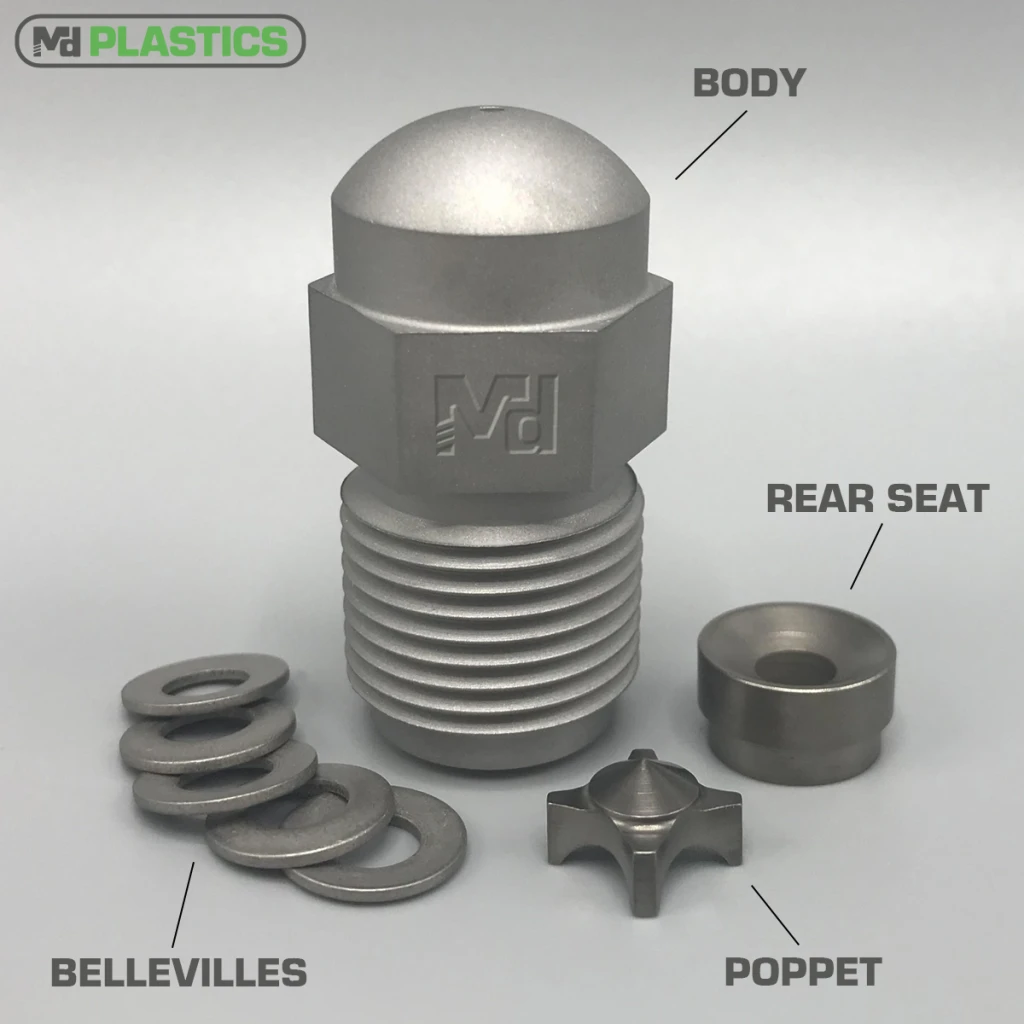

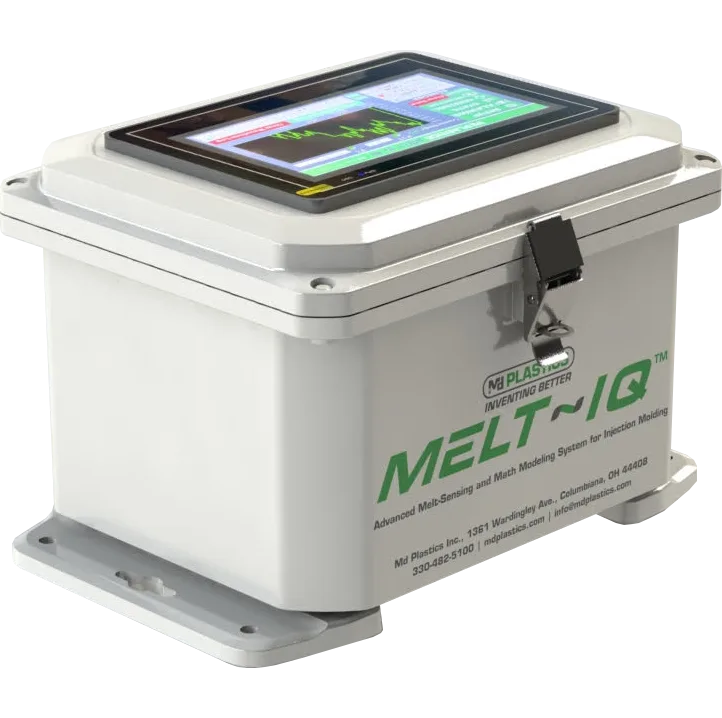

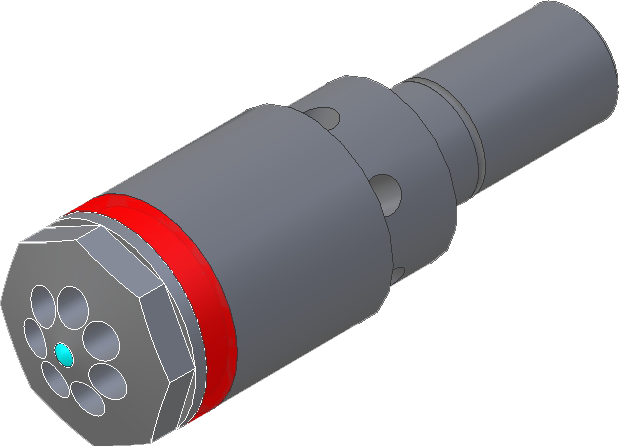

CertifiedComplete Range of Precision Injection Molding Products

Discover our comprehensive collection of innovative injection molding solutions including high-performance valves, precision nozzles, advanced plasticating systems, process monitoring equipment, specialty sensors, and premium purging compounds. Each product is engineered for optimal performance, reliability, and cost-effectiveness in demanding manufacturing environments.