Made in USA

Made in USABetter Melt Monitoring

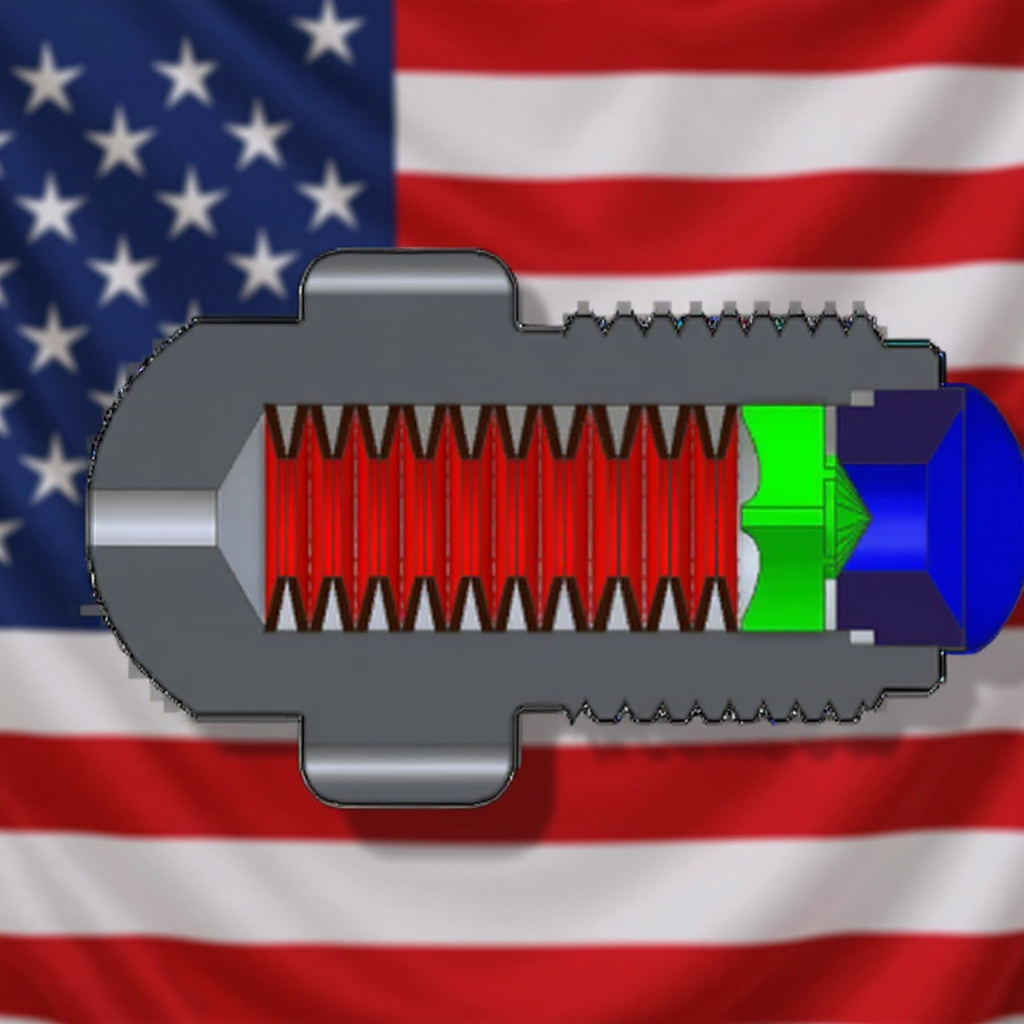

Discover our revolutionary monitoring and control systems designed to optimize injection molding processes. Our patented Temp-Sense™ Melt Sensor technology paired with our Melt-IQ™ and Melt-Profiler™ Melt Monitoring systems provide real-time melt temperature monitoring, quality control, and process optimization. We deliver precision solutions that reduce waste, improve part quality, and maximize profitability for molders worldwide.