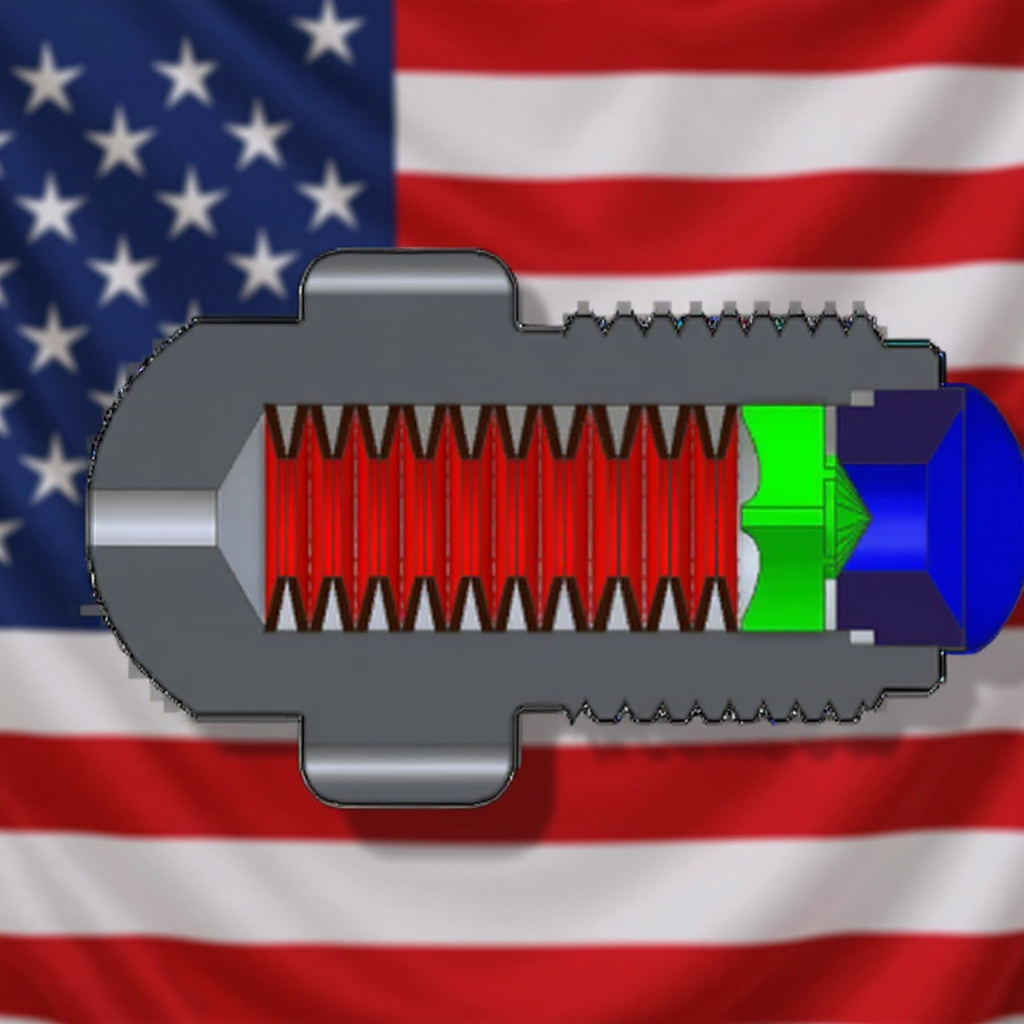

Made in USA

Made in USABetter Melt Systems

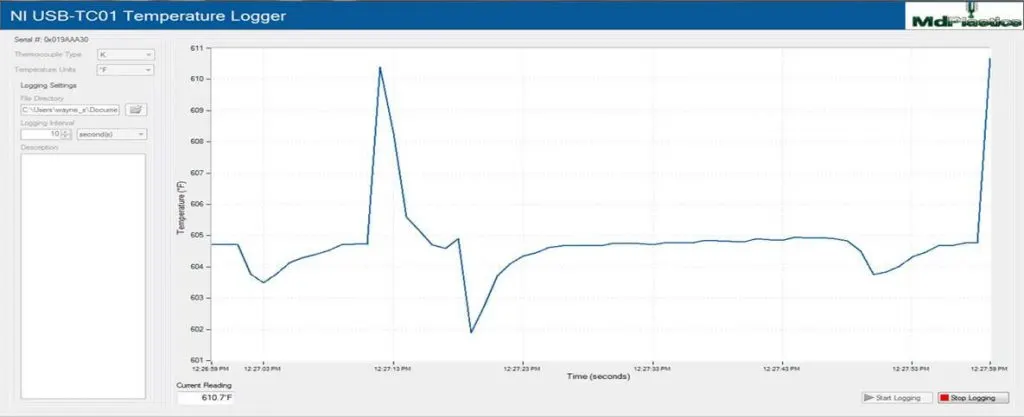

Discover our revolutionary Inject-EX™ Plasticating Systems designed to optimize injection molding processes. Our patented technology delivers superior melt quality, precise control, and enhanced productivity. These cutting-edge systems provides unmatched performance for molders seeking to maximize efficiency, reduce waste, and achieve consistent part quality in their manufacturing operations.