Technical Specifications

Advanced dispersive mixing screw engineered for exceptional melt homogenization, throughput, and purge performance.

Engineered for Superior Performance

Our patented Posi-Melt™ technology delivers unmatched melt quality and processing efficiency across all polymer types.

Patented Technology

Proprietary feed screw technology that alters flight pitch and root through the melting section, making them un-tangential to disrupt laminar flow for superior mixing.

Enhanced Melt Quality

Increases plastic exposure to barrel wall by up to 60%, delivering uniform homogenized melt with consistent temperature and material distribution.

Faster Changeovers

Quicker color and material changeovers reduce downtime and increase productivity, leading to lower manufacturing costs and improved operational efficiency.

Complete Pressurization

Complete pressurization throughout ensures excellent conveying, melting, and pumping performance with positive pumping angle and major flight OD wiping action.

High Throughput

Designed for low pressure drop and high throughput with appropriate leading and trailing edge radii to avoid low-velocity sections and maximize pressure.

Versatile Applications

Suitable for injection molding, extrusion, blow molding, LSR applications, 3D printing, rubber machinery, and corrosion-resistant environments.

Frequently Asked Questions

What makes the XLA mixer specoal versus other mixing designs?

There are "rules" for designing mixing sections and the XLA design meets and exceeds these rules better than any design in the industry.

Which polymer materials can I use a XLA mixing section on?

We have used a XLA mixing section on everything from LCP to CPVC. The most crystalline to the most amorphous materials on the market, with great success in injection molding and extrusion applications.

Industries We Serve

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Medical Devices

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Consumer Electronics

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Additive Manufacturing

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Plastic Processing

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Complete Plasticating Solutions

Explore our comprehensive range of complementary products designed to optimize your entire plasticating system performance.

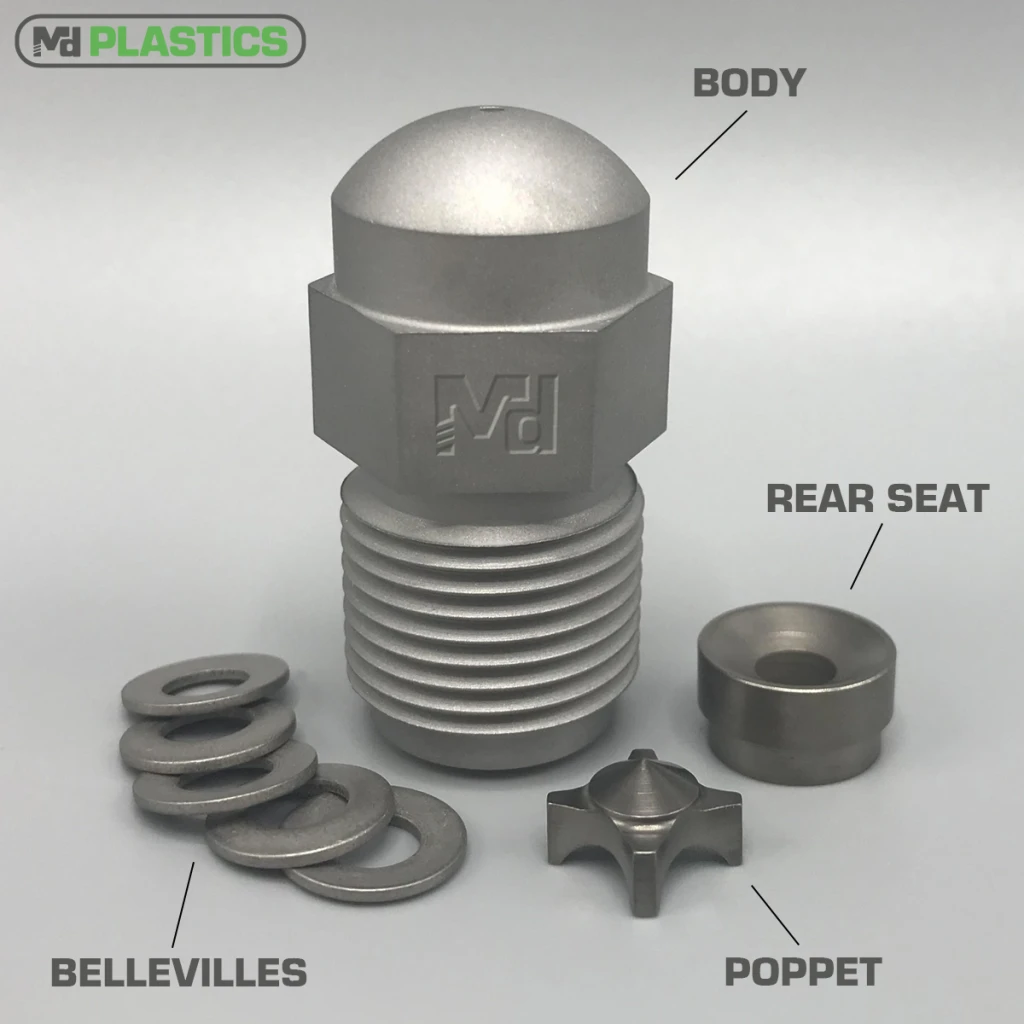

MDP™ Performance Non-Return Valve

Revolutionary valve with patented design featuring low pressure drop for improved hydraulics, precise shutoff, and extended wear life of 6-7 years with all polymers.

Mini-Shut™ Automatic Shut-Off Nozzle

Cost-effective solution eliminating drooling and stringing with instantaneous shutoff, free material flow with minimal pressure loss, and compatibility with all machine sizes.

Inject-EX™ Plasticating System

Revolutionary system with stationary Posi-Melt™ screw providing consistent output-recovery time, ultra-precise shot control, and enhanced energy efficiency with smaller footprint.

Need a Custom Plasticating Solution?

Speak directly with Mike Durina for personalized consultation and custom screw design tailored to your specific requirements.

Let's Optimize Your Processing Together

Ready to experience the benefits of Posi-Melt™ technology? Contact us for a custom consultation and quote tailored to your specific application.

For immediate assistance, call (330) 482-5100 or email us at [email protected]

For immediate assistance, call (330) 482-5100 or email us at [email protected]