Technical Specifications Overview

Comprehensive technical details for the Melt-Profiler™, designed for precise injection molding process monitoring.

WHY YOU NEED THE The Melt-Profiler™ System

One Temp-Sense™ Sensor

Precision temperature monitoring for optimal mold performance. Features a 1/2" rear opening with 7/8-14 threading, compatible with any radius and orifice sizes ranging from 1.5mm to 9mm. This versatile sensor delivers real-time temperature data to ensure consistent melt quality and prevent defects. Ideal for injection molding machines up to 68 oz. shot capacity, the Temp-Sense™ Sensor helps maintain tight process control and reduces scrap rates.

One Stand-Alone Model 603 Data Acquisition Device (DAQ) with Audible Alarm and Dual Temp-Sense™ Sensor Capability

Professional-grade monitoring system designed for comprehensive melt temperature analysis. The Model 603 operates independently with built-in display and audible alarm functionality, providing immediate alerts when temperatures deviate from specified parameters. Capable of simultaneously reading two Temp-Sense™ sensors, this unit enables multi-point temperature profiling across your nozzle or hot runner system. Features intuitive controls for setting alarm thresholds, reviewing historical data, and tracking temperature trends. The stand-alone design means no computer required for basic operation, though USB connectivity allows for advanced data logging and analysis when needed. Perfect for quality control, process validation, and troubleshooting temperature-related defects. Ensures consistent melt quality and helps prevent costly production issues before they occur.

Engineered for Precision Control

Advanced melt temperature monitoring technology that transforms injection molding quality control and process optimization.

Real-Time Temperature Monitoring

Provides continuous monitoring of in-line melt temperature during the injection molding process, ensuring optimal processing conditions throughout production runs.

Audible Alarm System

Features built-in audible alarms that alert operators immediately when melt temperature falls outside acceptable processing ranges, preventing defective parts.

Dual Sensor Capability

Can read two sensors simultaneously, allowing for comprehensive monitoring of multiple zones or comparison testing for enhanced process control.

Easy Installation & Setup

Stand-alone system requires minimal setup with sensors installed in nozzle body or end cap, making it accessible for existing molding operations.

Process Optimization

Enables understanding of how machine settings and environmental changes affect polymer melt, facilitating continuous process improvement and quality enhancement.

Cost-Effective Solution

Very affordable way to ensure melt temperature is where it needs to be, reducing scrap rates and improving overall production efficiency.

Frequently Asked Questions

How many sensors can the system monitor simultaneously?

The Melt-Profiler™ can read two Temp-Sense™ sensors simultaneously, allowing for comprehensive monitoring of multiple zones or comparison testing for enhanced process control.

What components are included with the system?

The system includes one Temp-Sense™ sensor, one stand-alone model 603 Data Acquisition Device (DAQ) with audible alarm, and a CD with proprietary data logger software for complete monitoring capability.

Where are the sensors installed on molding machines?

Temp-Sense™ sensors are installed in the nozzle body or end cap of molding machines. Customers are responsible for machining the hole for sensor placement, and phone consultation is available for installation guidance.

What patent technology does the system utilize?

The system utilizes specially fabricated Temp-Sense™ micro-bead sensors protected by U.S. patents 7,585,166 and 6,649,095, ensuring reliable and precise temperature measurement technology.

Industries We Serve

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Medical Devices

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Consumer Electronics

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Additive Manufacturing

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Plastic Processing

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Explore Our Complete Monitoring Solutions

Discover our full range of advanced melt monitoring and plasticating technologies designed to optimize your injection molding processes.

Inject-EX™ Plasticating System

Revolutionary plasticating system with stationary Posi-Melt™ screw providing consistent output-recovery time and ultra precise shot control with patented mechanical shut-off mechanism.

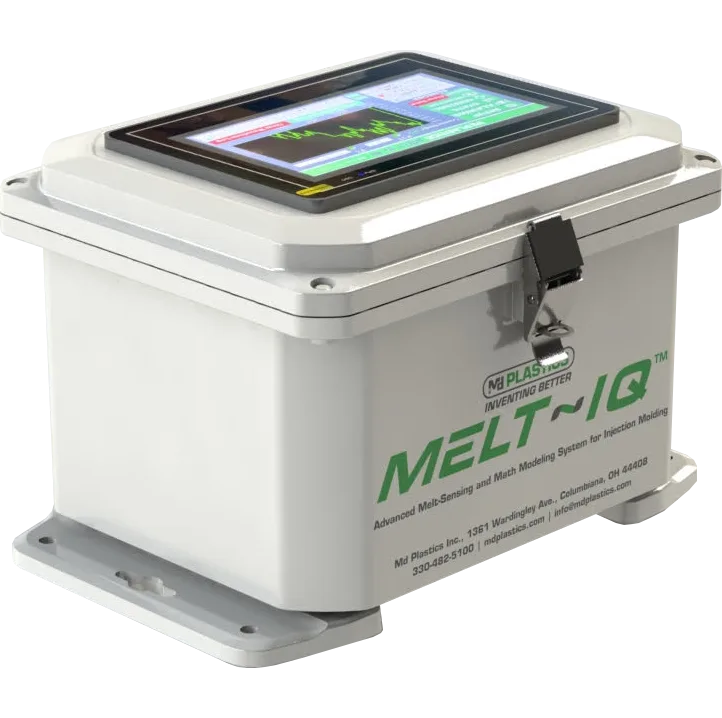

Melt-IQ™ System

Advanced Melt-Sensing and Math Modeling System that knows when a Good or Bad part is made, measures real time melt temperature and turns any machine into a 5-Star quality control manager.

Need Custom Process Solutions?

Our injection molding experts can help design the perfect monitoring solution for your specific application and requirements.

Ready to Improve Your Process Control?

Get in touch with our injection molding experts to discuss how the Melt-Profiler™ II System can optimize your production quality and efficiency.

For immediate technical support, call (330) 482-5100 or email us at [email protected]

For immediate technical support, call (330) 482-5100 or email us at [email protected]