Technical Specifications at a Glance

DON'T JUST TAKE OUR WORD WATCH TO SEE HOW IT WORKS

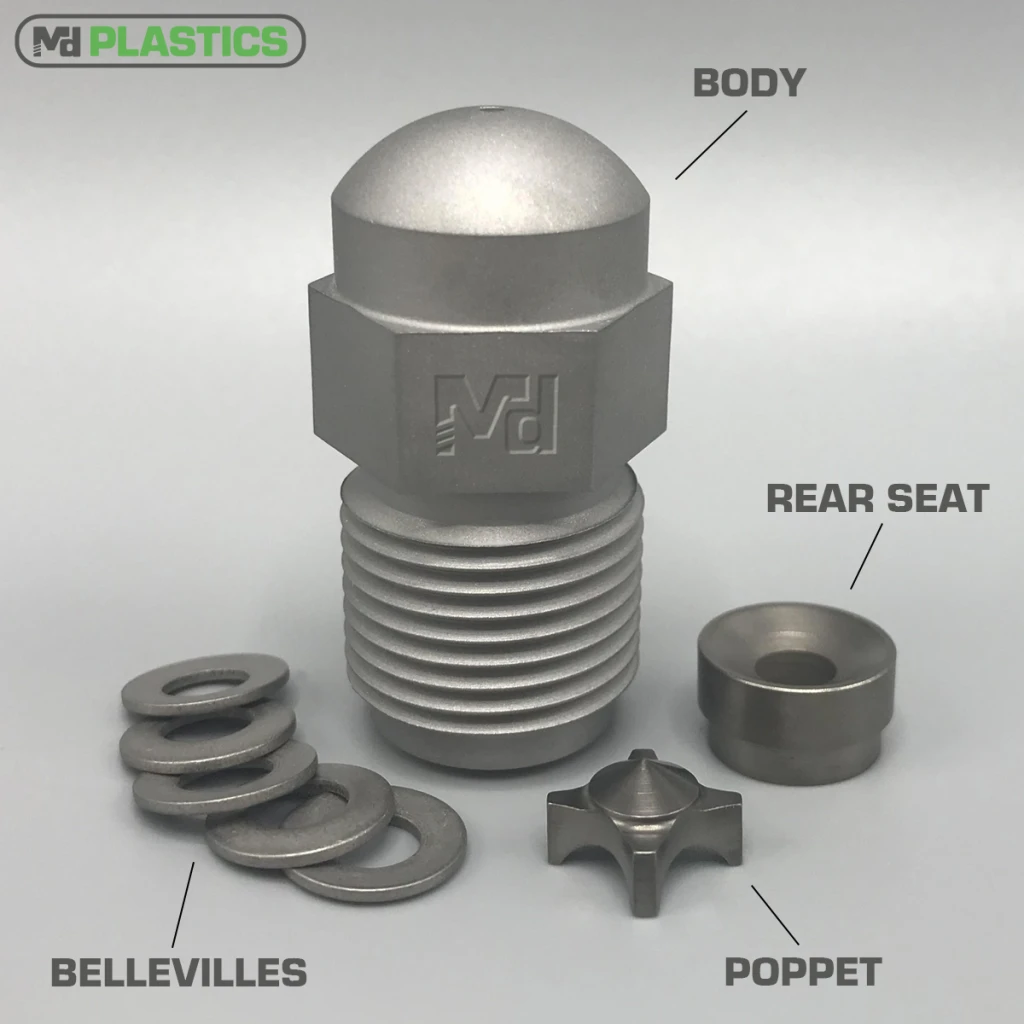

Engineered for Superior Performance

The MDP™ Performance Non-Return Valve delivers unmatched reliability and efficiency for injection molding operations worldwide.

Low Pressure Drop

Patented hydraulic design features the lowest pressure drop in the industry, improving overall system efficiency and reducing energy consumption while maintaining optimal flow characteristics.

Precise Shutoff Control

Delivers exceptional shutoff performance with low part weight variance, ensuring consistent shot-to-shot quality without requiring melt decompression assistance for optimal operation.

Universal Polymer Compatibility

Works seamlessly with all polymer types from CPVC to LCP, including filled and unfilled materials, making it the perfect solution for diverse manufacturing requirements.

Extended Service Life

Tungsten carbide retainer pin and tool steel ring construction provide exceptional wear resistance, delivering 6-7 years of reliable service life in demanding applications.

Easy Implementation

Simple three-step process: request quote, install valve, and immediately start saving time, money, and materials with minimal disruption to existing operations.

Proven Reliability

Trusted by injection molders and machine OEMs worldwide, the patented design eliminates common valve problems while ensuring consistent performance across all application scenarios.

Frequently Asked Questions

Can the MDP™ valve work with all polymer types?

Yes, the MDP™ valve is compatible with all resin groups including CPVC to LCP, both filled and unfilled polymers, making it suitable for any injection molding application regardless of material choice.

What size ranges are available for the MDP™ valve?

The MDP™ Performance Non-Return Valve is available in all sizes from 14mm to 260mm diameter, accommodating virtually any injection molding machine configuration and application requirement.

How long does installation and implementation typically take?

Implementation follows a simple three-step process: request quote, install valve, and start saving. Installation is straightforward and can typically be completed during routine maintenance with minimal production downtime.

Is custom design consultation available for specific machine configurations?

Yes, owner Mike Durina provides personalized custom design consultation for specific machine makes and models, ensuring optimal valve configuration and performance for your unique application requirements.

Industries We Serve

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Medical Devices

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Consumer Electronics

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Additive Manufacturing

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Plastic Processing

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Explore Our Complete Product Line

Discover our full range of innovative plasticating components and systems designed to optimize your injection molding operations.

Mini-Shut™ Automatic Shut-Off Nozzle

Simple, cost-effective solution that eliminates melt-decompression, stringing, and drooling with instantaneous shutoff and reliable performance for all machine sizes and polymers.

Inject-EX™ Plasticating System

Revolutionary system with stationary Posi-Melt™ screw providing consistent output-recovery time, ultra precise shot control, and enhanced energy efficiency with smaller footprint requirements.

Need a Custom Solution?

Get personalized consultation from our experts to optimize your injection molding process performance.

Let's Optimize Your Injection Molding Process

Ready to experience the benefits of the MDP™ Performance Non-Return Valve? Get in touch with our team for a custom consultation.

For immediate technical support, call (330) 482-5100 or email us at [email protected]

For immediate technical support, call (330) 482-5100 or email us at [email protected]

.png)