Technical Specifications Overview

Comprehensive technical details of the revolutionary Inject-EX™ Machine design and capabilities.

DON'T JUST TAKE OUR WORD WATCH TO SEE HOW IT WORKS

Engineered for Excellence

The Inject-EX™ System delivers superior performance through innovative design and advanced plasticating technology.

Precise Shot Control

Ultra precise shot control with patented mechanical shut-off mechanism and plunger technology ensures consistent part quality and minimal waste in every injection cycle.

Consistent Recovery Time

Stationary Posi-Melt™ screw provides consistent output and recovery time, eliminating disruption of solids bed compaction for reliable processing performance.

Energy Efficiency

Inline polymer flow design reduces energy usage and pressure drop while maintaining optimal processing conditions with smaller footprint per output ratio.

Advanced Process Control

Temp-Sense™ Melt Sensor provides real-time melt density verification and good-bad part discrimination using Melt-Profiler™ technology for superior quality control.

Easy Installation

Can be retrofitted onto existing injection molding machines or integrated into new systems through collaboration with EdeX Technology Co., Ltd. for flexible implementation.

Reduced Carbon Footprint

Fewer parts compared to traditional screw/pot machine design results in smaller carbon footprint while maintaining superior performance and reliability.

Frequently Asked Questions

Can the Inject-EX™ System be retrofitted to existing injection molding machines?

Yes, the Inject-EX™ System can be retrofitted onto existing injection molding machines or integrated into new full Inject-EX™ IMM systems through our collaboration with EdeX Technology Co., Ltd. Our team provides direct consultation for custom system design and implementation.

What types of materials are compatible with the Inject-EX™ System?

The Inject-EX™ System is designed to process both thermoplastics and thermoset LSR (Liquid Silicone Rubber) materials. It's particularly effective for thermoplastics processing, LSR processing, recycling applications, and any injection molding operations requiring improved melt quality and precise shot control.

How does the Temp-Sense™ Melt Sensor improve part quality?

The Temp-Sense™ Melt Sensor provides real-time melt density verification and enables good-bad part discrimination using Melt-Profiler™ technology. This allows for immediate quality control feedback and helps prevent defective parts from being produced, reducing waste and improving overall production efficiency.

What support and documentation is available for the Inject-EX™ System?

Md Plastics provides comprehensive support including explainer videos, machine list PDFs, direct consultation with owner Mike Durina for custom system design, and quote requests through our website form. We also offer retrofit services and collaboration with EdeX Technology for complete system solutions.

Industries We Serve

Serving diverse sectors with specialized plasticating solutions for enhanced manufacturing performance.

Automotive

Precision plasticating solutions for high-quality automotive components requiring consistent melt quality and performance.

Medical Devices

Advanced plasticating technology ensuring purity and precision for critical medical device manufacturing applications.

Consumer Electronics

Innovative solutions for complex electronic housings and components requiring superior surface finish and dimensional accuracy.

Additive Manufacturing

Specialized plasticating systems for 3D printing and additive manufacturing, delivering consistent filament quality and material flow.

Plastic Processing

Comprehensive plasticating solutions for general plastic processing applications across various manufacturing sectors.

Advanced Manufacturing Process

Our revolutionary Inject-EX™ System utilizes innovative stationary screw technology to deliver consistent, high-quality plasticating performance.

Material Feed & Preparation

Raw polymer pellets are fed into the system where they encounter the stationary Posi-Melt™ screw design. Unlike traditional systems, our approach ensures consistent material handling from the very beginning.

Stationary Screw Melting Process

The revolutionary stationary Posi-Melt™ screw provides consistent output and recovery time. Each pellet experiences the same heat and shear history, eliminating the deficiencies of traditional reciprocating systems.

Temp-Sense™ Melt Monitoring

The integrated Temp-Sense™ Melt Sensor provides real-time melt density verification and temperature monitoring. This advanced sensor technology ensures optimal processing conditions throughout the cycle.

Superior Melt Homogenization

The inline polymer flow design along a single axis ensures superior melt homogenization. This eliminates the variability common in traditional systems and delivers consistent material properties.

Advanced Pressure Management

The pressure vessel with tight diametrical fit enables precise mass displacement and pressure control. This design reduces energy usage and pressure drop while maintaining optimal processing conditions.

Ultra Precise Shot Control

The patented plunger head with kinetic energy springs provides instantaneous independent mechanical shutoff. This ultra-precise shot control ensures consistent part weight and minimizes material waste.

Good-Bad Part Recognition

The integrated Melt-Profiler™ technology enables real-time good-bad part discrimination. This advanced quality control system prevents defective parts and ensures consistent production quality.

Efficient Cycle Reset

The system efficiently resets for the next cycle with minimal energy consumption and optimal recovery time. The stationary design eliminates unnecessary movements and reduces cycle time variability.

Explore Our Complete Plasticating Solutions

Discover our comprehensive range of innovative plasticating components and systems designed to enhance your injection molding operations.

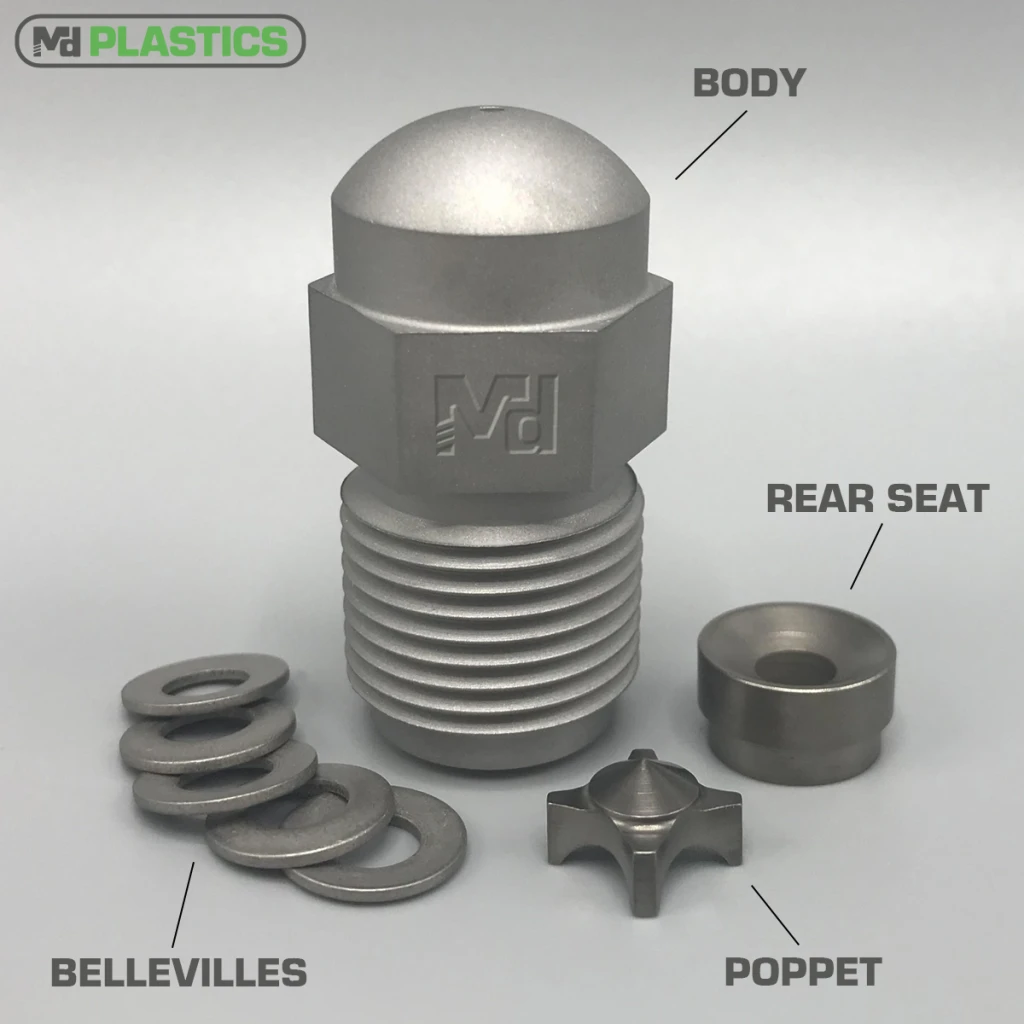

MDP™ Performance Non-Return Valve

Features patented design with low pressure drop for improved hydraulics, precise shutoff and minimal part weight variance, working with all polymers and machine sizes from 14-260mm.

Mini-Shut™ Automatic Shut-Off Nozzle

Simple, cost-effective solution that eliminates melt-decompression, stringing, and drooling while shutting off instantaneously as soon as melt flow stops with almost no loss of pressure.

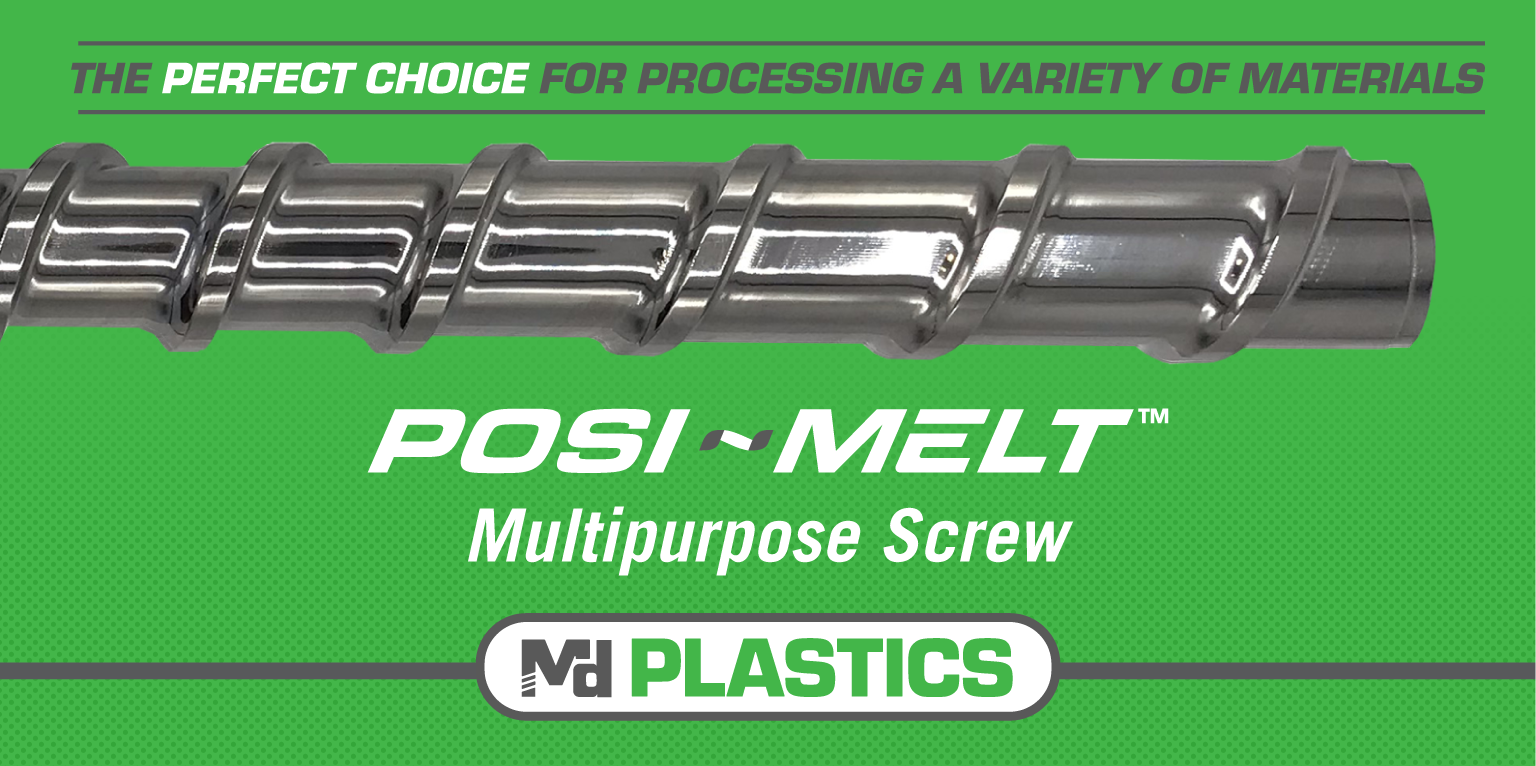

Posi-Melt™ Plasticating Screws

Patented feed screw technology with altered flight pitch and root through melting section, increasing plastic exposure to barrel wall by up to 60% for uniform homogenized melt and quicker changeovers.

Need a Custom Solution?

Our engineering team can design custom plasticating systems tailored to your specific requirements and processing needs.

Ready to Transform Your Manufacturing Process?

Connect with our team to discuss how the Inject-EX™ System can revolutionize your injection molding operations with superior precision and efficiency.

For immediate assistance, call (330) 482-5100 or email us at [email protected]

For immediate assistance, call (330) 482-5100 or email us at [email protected]